Editor’s Note: This article has been edited to reflect 2024 pricing on all New Tech Machinery portable roof and wall panel machines and includes updated information.

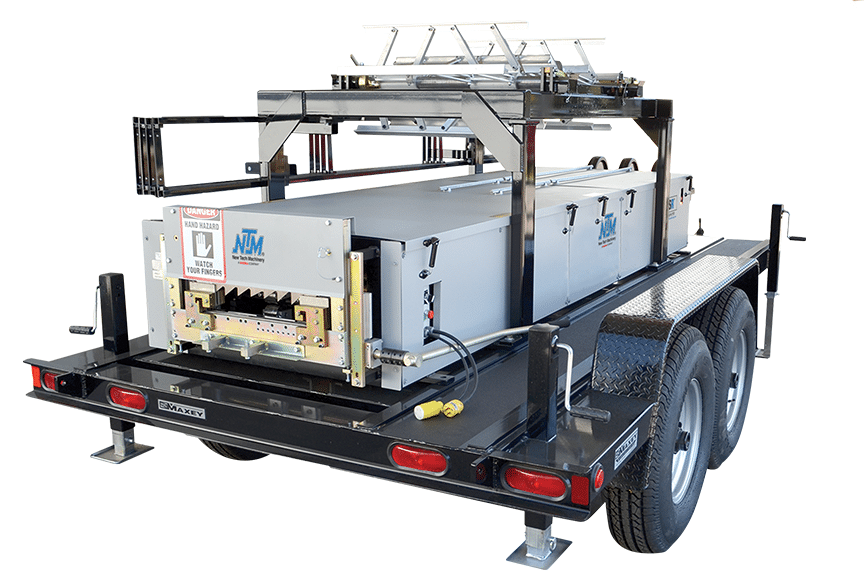

Purchasing a portable rollforming machine requires a significant investment. The size and type of roof panel machine you need will determine how much you need to spend. Of course, the return on your investment will mean that it pays for itself many times over, and NTM machines, if taken care of, can last decades.

The cost of your portable rollformer isn’t the only consideration. You also have to think about accessories and configurations, machine maintenance, material costs, labor, transportation, etc. If you’ve been running a metals operation you’re already familiar with those expenses and have most likely worked out a budget. If you’re just starting out, you’ll want to take those extra costs into account.

At New Tech Machinery (NTM), we’ve supported contractors and manufacturers with our portable metal roof and wall panel and gutter machines for over 30 years. This means not only providing quality rollformers and accessories, but educating our customers on the correct operation of our machines, as well as highlighting issues in the industry. For more information on how to use our machines, visit our Learning Center.

In this article, we will cover:

- The cost and price of some portable roof and wall panel machines

- What factors may affect the price of a rollformer

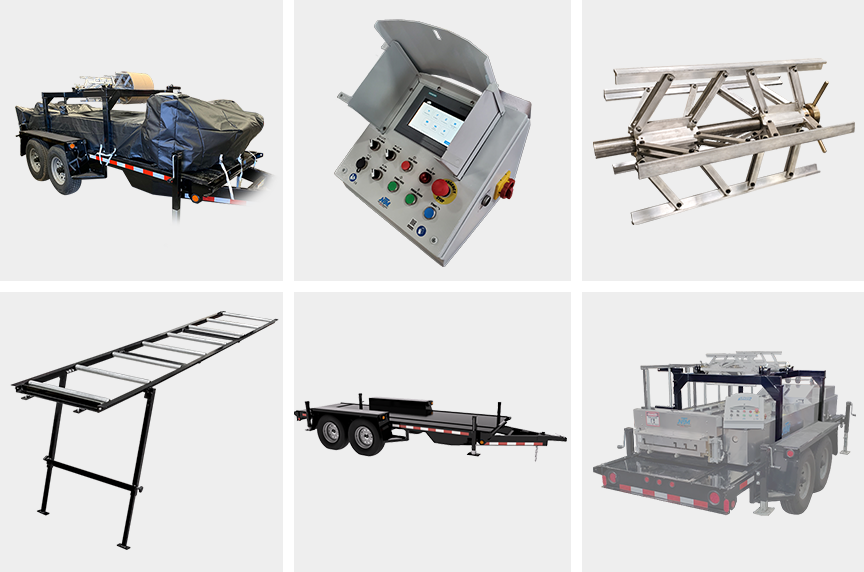

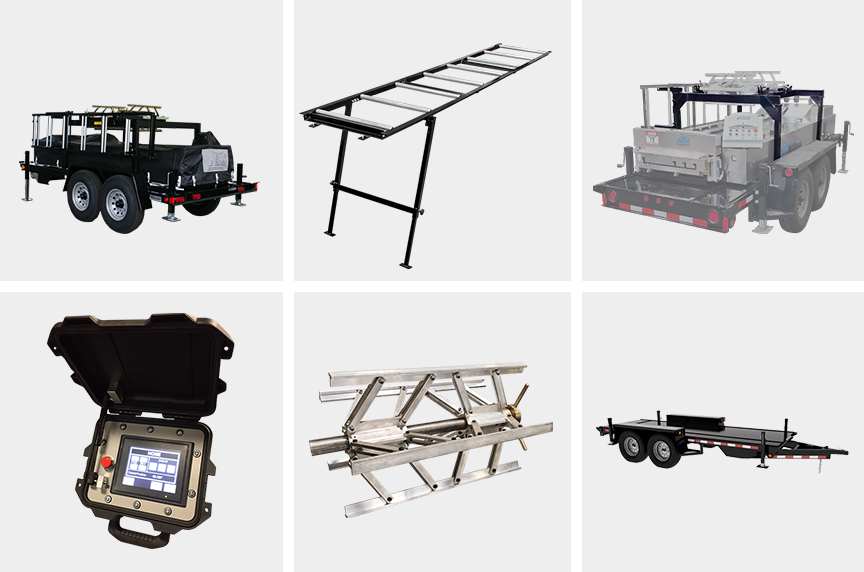

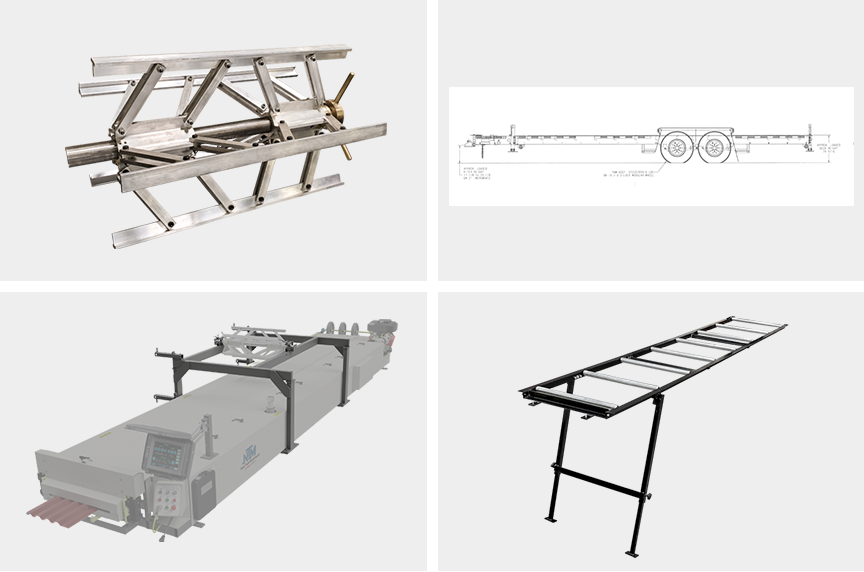

- Common machine accessories and add-ons you can choose from

- What to look for as you purchase a new or used machine

2024 Cost & Price of a Portable Roof or Wall Panel Rollforming Machine

The cost of a portable rollformer depends on several factors, starting with the type of machine you need for your operation. Before purchasing, you’ll want to think about your operational needs not only today, but in the future. From our experience, it’s better to purchase a larger machine and grow into it rather than a smaller machine that you grow out of. However, there’s nothing that says you can’t have more than one portable rollformer, and many of our customers do. Buy today for tomorrow’s jobs, we like to say.

If you’re looking for a complete machine configuration with accessories typical for most metal roofing applications who are primarily transporting their machine to a job site, want automatic computer operation of their machine, and handle a lot of regular jobs, we’ve included a range of prices for a more realistic cost analysis.

SSQ II™ MultiPro Roof Panel Machine

The starting price of the SSQ II is $79,800 USD and includes:

- Your choice of gas or electric Quick-Change™ Power Pack

- Powder-coated painted covers

- Your choice of one profile tooling set

- Choice of bead, v-rib, or striation rib rollers with frame

- Hydraulic drive and shear and manual controller

- Push Button RUN/JOG Controls at Entry & Exit Ends

- Power Interruption Safety Circuit

- UL Rated Panels (Must Be Certified by UL for Recognition)*

*Not all panel profiles have UL ratings associated with them. Check with your account manager for more information.

Customers who buy the SSQ II (without notching) typically end up paying between $106,000 USD and $121,000+ USD for a machine with the following accessories (including everything in the base price):

- UNIQ® Automatic Control system $15,300

- Trailer $16,900

- Dual overhead reel stand, machine mount $3,050

- Canvas cover kit $3,150

- 2 expandable arbors $2,425 each

- Variable height run-out table $895 per 10′ section

The starting price for the SSQ II with the optional notching function is $127,000+ USD* and includes:

- Choice of gas or electric Quick-Change Power Pack

- Choice of one set of profile tooling sets

- Notching system with one pair of notching cartridges

- Hydraulic drive and shear

- Choice of bead, v-rib, or striation rollers with frame

*UNIQ® Automatic Controller (required to run notching system) additional $15,300

A lot of customers who purchase the SSQ II with notching typically end up paying between $ 164,000 USD and $200,000 + USD for this machine configuration (including what’s listed above):

- NATM-compliant 12,000 lb. capacity tandem axle trailer with four independent jack stands, crane lifiting eyes, electric brakes, shear scrap tray, and breakaway kit $16,900

- Dual overhead reel stand, machine mount $3,050

- Canvas cover kit $3,150

- 2 expandable arbors $2,425 each

- Variable height run-out table $895 per 10′ section

SSH™ MultiPro Roof Panel Machine

The starting price of the SSH machine is $62,160 USD and includes:

- Choice of gas or electric Quick-Change Power Pack

- Choice of one panel profile

- Hydraulic drive and shear

- PLC computer batch / length controller

- Choice of bead, v-rib, or striation rib rollers with frame

Typically, those who purchase the SSH machine for their business may spend upwards of $84,000 to $89,000+ USD for this particular machine configuration (including everything listed above):

- NATM-compliant 12,000 lb. capacity tandem axle trailer with four independent jack stands, crane lifiting eyes, electric brakes, shear scrap tray, and breakaway kit $16,900

- Dual overhead reel stand, machine mount $3,050

- Canvas cover kit $2,690

- 2 expandable arbors $2,425 each

- Variable height run-out table $895 per 10′ section

SSR™ MultiPro Jr. Roof Panel Machine

The SSR MultiPro Jr. machine starts at $38,850 USD. This price includes:

- Electric 110V Motor (220V/50Hz motor also available for overseas clients)

- Choice of one panel profile

- Overhead reel rack

- One expandable arbor

- 20’ of run-out table

- Choice of bead, v-rib, or striation rib rollers with frame

- Manual shear

- 100’ extension cord

For typical metal roofing projects using the SSR machine, customers may pay between $61,000 USD to $66,000+ USD, depending on the configuration of these add-on options and what’s included in the base price:

- NATM-compliant 12,000 lb. capacity tandem axle trailer with four independent jack stands, crane lifiting eyes, electric brakes, shear scrap tray, and breakaway kit $16,900

- Additional expandable arbor 16″ to 20″ ID $2,425

- EZ-Counter Computerized Length Controller $2,900

- Canvas cover kit $2,690

- Variable height run-out table (specifically for SSR machines) $550 per 10′ section

5VC-5V CRIMP™ Roof Panel Machine

Starting price for the 5VC-5V CRIMP machine is $63,350 USD and includes:

- Gas or electric Quick-Change Power Pack

- Forming rollers

- Hydraulic drive and shear

When someone typically purchases the 5VC machine with a loaded configuration, the price can increase somewhere between $96,000 USD to $100,000+ USD. This configuration includes everything in the base price and also:

- NATM-compliant 12,000 lb. capacity tandem axle trailer with four independent jack stands, crane lifiting eyes, electric brakes, shear scrap tray, and breakaway kit $16,900

- NTM controller (PLC) $10,500

- Dual overhead bolt-on reel stand, machine mount $3,050

- Expandable arbor 16″ to 20″ ID $2,425 each

- Variable height run-out table $895 per 10′ section

- Canvas cover kit $2,690

- Striation assembly for 5VC Machine $6,600

WAV™ Wall Panel Machine

The WAV wall panel machine’s price starts at $195,000* USD and includes:

- UNIQ® Automatic Control System

- Gas power

- On-site setup and training (within continental U.S.)

*requires purchase of a chosen trailer or fixed base/ platform at an additional price (see below)

The WAV machine could cost between $213,000 USD to $220,000+ USD for the following portable configuration (in addition to the machine’s standard features above):

- 12,500 lb. capacity tandem axle trailer for single overhead reel rack $23,000

- 23,100 lb. capacity 3-axle trailer for triple overhead reel rack $29,200

- Single overhead reel rack (supports 3,000 lbs.) $4,300

- Triple overhead reel rack (maximum weight 4,000 lbs. per reel) $8,700

- Single free-standing decoiler $2,500

- Expandable arbor/ reel (maximum weight 4,000 lbs.) $2,425

- Variable height run-out table $895 per 10′ section

- Canvas cover kit $3,150

- WAV in-plant base $13,500

Roof Panel Rollforming Machine Cost Factors & Add-ons

Common Factors Affecting the Price of a Machine

You might be asking yourself: What makes one portable roof panel rollforming machine cost more than another?

The answer lies within the unique features and functions that a machine offers. For example, here are some items that tend to make a rollforming machine cost more:

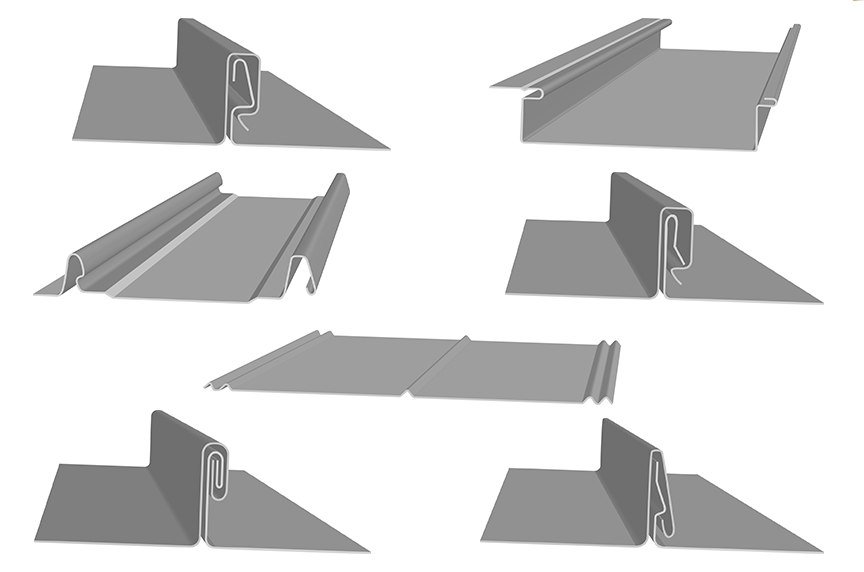

- Additional profiles – Roof panel machines used to produce more than one panel profile will increase the price. Profile roller systems range from $8,800 to over $34,000, depending on the complexity and nature of the panel profile.

- Notching – This is specifically for the SSQ II MultiPro. Notching is an expensive add-on, but it has become a must for both manufacturers and contractors as it saves labor time. If you’re installing, you don’t need an extra hand to notch for you. For panel manufacturers, you can charge extra for providing notching. Plus, snap lock profiles that are notched include a closure tab built-in to cap off leg ends at eaves and ridges.

- Computer-operated controllers –Upgrading to a PLC or the UNIQ Automatic Controller can add cost to the machine. However, it can reduce work time and save you money in the long run. In addition, computer controllers are much more accurate and user-friendly when measuring panel lengths versus using a tape-measurer.

What to Look for in a New Portable Roof Panel Machine

The best way to make sure you purchase the right portable roof panel machine is to be an educated consumer from the beginning, as this equipment is a significant part of your business and production.

You don’t necessarily want to buy the first new portable roof panel rollforming machine you look at. It’s important to compare and contrast attributes among the ones you’re interested in. When looking at your options, check for the following:

- Separate drive and forming rollers: The best rollforming machines tend to be those with separate drive and forming rollers. Separating the functions of the rollers results in less stress on the metal because the rollers aren’t forming and driving the metal at the same time. The forming rollers will also last longer if they aren’t under the additional stress of driving the metal through the machine.

- Post-cut or pre-cut shear: Advantages to pre-cut include creating a clean cut and allowing the user to hand-feed for low-volume production. Also, pre-cut shears require less maintenance. No die changes need to be made for varying profiles because cutting is done prior to rollforming. However, some panels run better on post-cut, like high-strength and heavy gauge steels. Also, shorter panels can’t be run with pre-cut shears, whereas post-cut can handle as short as 3″ or 4″ panels.

Post-cut and pre-cut differences:

- Post-cut – The metal part is formed first in the forming stations and cut AFTERWARD. One benefit of cutting after the panel is formed is that there are no length restrictions. Products can be cut as small as a few inches. The main disadvantage to post-cut is the high maintenance. The shear needs constant lubrication. Then there’s the expense and maintenance of cut-off dies.

- Pre-cut – The metal is cut BEFORE it goes through the forming stations at the entry end of the machine. Conversely to post-cut, there are minimum length restrictions on pre-cut machine shears.

Ultimately, most panels can be produced using either shear. Though the post-cut end may look a bit rougher, it’s worth noting that this edge gets tucked under, so it’s debatable whether it makes much difference. While the pre-cut may be more cost-effective and provide a cleaner cut, it isn’t ideal for every situation. Many contractors prefer the post-cut for this reason.

- Number of machine profiles/ profiles run: If you want to offer your customers a variety of profile options, you’ll want to ensure the new machine has the right tooling for the profiles you need. Some users purchase more than one machine so as not to change profiles because of strong demand. However, changeovers only take around 45 minutes.

- Materials run: make sure the machine runs the type of metal you plan to use. Most machines run aluminum, but only finished, not raw. Also, confirm that the machine can accommodate the gauge and widths of metal coil you plan to run.

- Controllers: Stock controllers tend to be limited, with start/stop and run/ reverse functions. Many rollforming companies offer upgrades with more sophisticated functions that allow batch control cut list uploads, coil calculators, and troubleshooting screens.

- Power: Portable machines may run on either gas engines or electric motors. If you’re using your machine in-plant, then you probably want to go electric to avoid gas fumes. However, if you plan to use your machine in-plant and out in the field, you may want both.

- Machine speed – Most portable rollformers run fast and consistently enough for the average metal roofing or wall panel jobs. That being said, some machines may run slower or quicker depending on the use of hydraulics, so be sure to verify the machine’s speed if speed of production is an issue.

- Warranties – Before you buy new equipment, always make sure you know about the warranties on the machine or the various parts that are offered with the purchase. Portable rollforming machine manufacturers offer varying warranties so it’s important you ask about what’s covered, what’s not covered, how to file a claim, and what would deny a warranty claim.

- Service / support, parts availability, and training – No one wants their new machine to run into issues, but it’s important you know what to do if a problem does occur. Always ask a manufacturer if they offer service / technical support and training for the machines they sell. Plus, check how quickly they are typically able to provide service or replacement parts when a machine is down. Also, ask about any costs associated with training.

- Machine size – The size or footprint of the machine (length and weight) can make a difference for some contractors. This is especially true if you don’t plan on purchasing a trailer for the rollformer because you already have another form of transportation with size restrictions. Also, you’ll need space to store the machine when not in use, either in a shop or enclosed trailer, unless you plan on having an in-plant setup.

What Should I Expect to Spend on a Rollforming Machine?

Buying a portable roof panel rollforming machine can give you a competitive edge in your region and take your business to the next level. But you want to make sure you’re buying the right machine with the accessories and options that you need. You should also consider the costs of maintenance, transportation, and insurance.

There’s no straight answer to how much you spend because it all depends on your operational needs. Start with choosing the machine that will fit your needs and budget. Add in the accessories you’ll need, as well as the cost of a trailer for transporting it. If you’re financing, figure payments into your monthly budget.

Keep in mind:

- The starting price of a roof panel rollforming machine normally doesn’t include many accessories or add-ons. Some manufacturers, like NTM, will include one set of tooling with your machine. However, some do not, and you’ll need to pay extra for any profile roller set.

- Many variables affect the cost of a portable rollformer, including versatility, accessories, hydraulics, automation, and drive systems. The SSQ II Multipro with notching will have more sophisticated components than, say, the SSR MultiPro Jr.

- Make sure the new machines you’re looking at offer the features and functionality you want, such as profiles (roller sets), pre- or post-cut shears, speed, etc.

- When purchasing used equipment, always go see the machine in person and run material in every panel profile and size the rollformer can produce before you make a decision to buy.

At New Tech Machinery, we’ve helped customers purchase and learn how to operate roof panel machines. Whether you’re a contractor, manufacturer, or someone looking to break into the industry, we’re dedicated to answering your questions and helping you find the best roof panel machine to fit your needs. Reach out to us anytime!