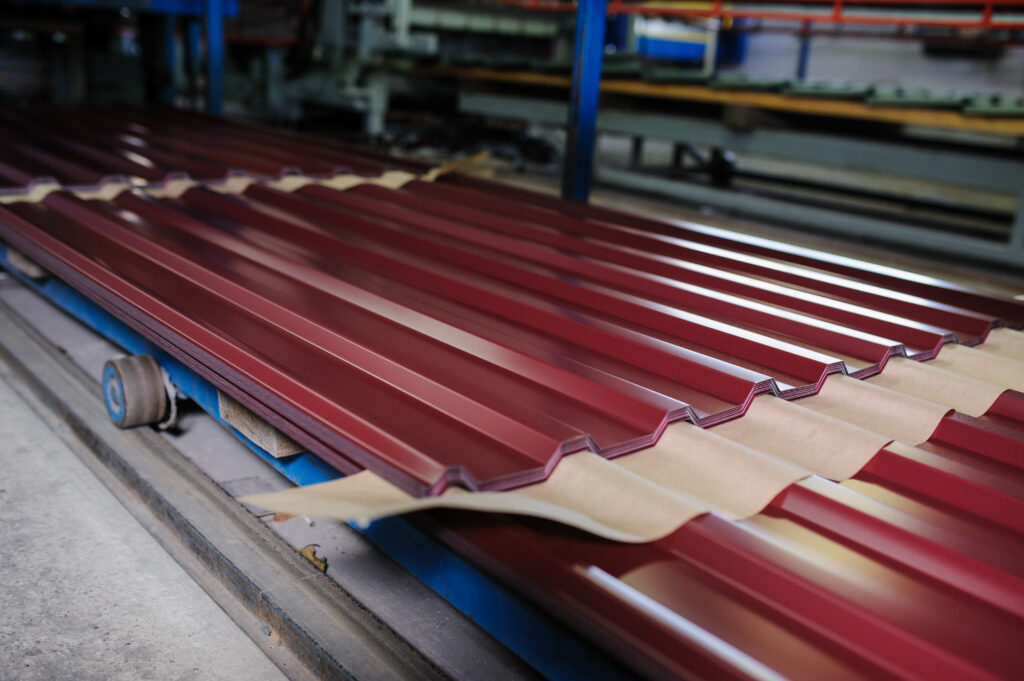

The demand for metal roof panels is growing in the construction industry, from factory-made to those fabricated on a portable rollforming machine. For both commercial and residential structures, metal roof panels offer durability and energy efficiency, and their aesthetic appeal is only increasing as metal companies continue to produce new colors, designs, and textures.

When it comes to sourcing metal panels for your project, you have two primary options: factory-made panels or panels custom-made from a portable rollforming machine. Each option has its own set of advantages and disadvantages. In this article, we’ll dive into the pros and cons of each. Whether you’re new to the industry or an old hand who’s been installing prefabricated factory panels, you’ll want to weigh your options.

As portable rollforming manufacturers, New Tech Machinery (NTM) has helped contractors build their metal roofing, wall panel, and seamless gutter businesses for over three decades. However, we also know that for some contractors, purchasing factory-made panels is a more practical solution for their operational needs.

In this article, you’ll learn:

- Factory panel pros and cons

- Portable rollformer pros and cons

- What to consider when purchasing a portable rollformer

Factory-Made Metal Panels

Factory Panel Pros

Consistency and Quality

Factory metal panels are mass-produced in controlled factory environments using long rollforming machines with multiple forming stations. The added forming stations ensure uniformity in dimensions, finish, and quality. The size of these in-plant machines allows for high-speed production with consistent quality.

However, many factory suppliers also use use portable rollformers such as NTM machines for quicker changeovers and “chop and drop” operations.

Faster Installation

Factory-made panels arrive on-site ready to install, saving job site time and labor costs. Contractors can install them quickly, accelerating project timelines. Also, as an installer, you can focus exclusively on installing the panels, not on operating the machine, forming panels, or transporting the rollformer between jobs.

Wider Variety

Manufacturers offer an extensive range of finishes, colors, and profiles, allowing builders to choose panels that meet the project’s design requirements. They can accommodate an array of different profiles, so you’re not limited to those you’ve acquired for your machine.

With your own machine, you may have to purchase additional profiles to meet your customers’ varying needs. However, the choices of coil colors, patterns, and finishes have expanded rapidly in recent years, and metal companies continually develop new styles.

No Maintenance or Machine Costs

By purchasing from a manufacturer, you avoid the costs of maintaining a machine, dealing with profile changeovers, and transporting the rollformer between worksites. Also, you don’t have the initial cost of purchasing the metal panel machine and its accessories. You only need to have the materials delivered from the supplier on time and in good condition, with no mistakes on the order.

Factory Panel Cons

Limited Customization

Factory-made panels are often produced in standardized sizes and shapes, or according to order specifications. Customization options are limited, making it challenging to address all design requirements. Also, you can’t make on-site adjustments. Every panel size must be calculated in advance, which can add to material waste during installation.

Increased Transportation Costs

Shipping large and heavy factory-made panels to construction sites can incur significant transportation expenses, especially for long-distance projects. This also risks limited transportation options or scheduling issues if you suddenly need a quick delivery from the plant. For example, if a panel size was miscalculated, or you received the wrong color or size, you’re limited by the transportation available to deliver the replacement panels as quickly as possible.

Another risk with transportation is damage to the panels. Panels often arrive scratched, bent, or dented due to careless handling. This leads to panel replacement with added costs, more delivery scheduling, and job delays.

Limited Panel Availability

Desired panel profiles or materials may not be available when you need them. Profile changeovers for factory rollforming machines are laborious and time-consuming, so depending on their scheduling and workload, changeovers between profiles to accommodate your order may take days or even weeks.

Transportation can limit panel lengths, so longer panels may have to be segmented to fit into a transport vehicle. Portable rollformers, on the other hand, can fabricate panels of any length, which makes them suitable for large industrial or commercial projects.

Also, factory suppliers may run into delays, which means pushing back your timeline in completing the job. Your customers won’t appreciate this, nor will other contractors working on the project, even if it’s not your fault. Such delays can damage your business’s reputation.

Custom-Made Panels from Portable Rollforming Machine

Portable Rollformer Pros

High Customization

Panels produced from a portable rollforming machine are highly customizable. Contractors can create panels of varying lengths, shapes, and profiles to fit the project’s exact specifications. Plus, adjustments can be made on-site if there is size variation, or if initial measurements were incorrect. Also, most machine controllers allow you to upload cut lists, making it easy to run multiple panels in sequence.

Cost-Efficiency

Custom-made panels reduce material waste because panels are produced on-site as needed to specific lengths, much more accurately than factory-produced panels. This can lead to cost savings, especially for smaller projects. Prefabricated panels cost much more per linear foot, so many in the industry switch to portable rollformers. Plus, you not only have reduced material costs but also downtime if your crew is left waiting on panels that don’t arrive on time. Finally, contractors with portable rollformers have more control over their materials and panel production.

Production Capacity

Portable rollforming machines can handle a high volume of large-size panels, making them suitable for large-scale projects. When it comes to panel length, portable rollformers can form panels much longer than factory transport trucks can accommodate. Portable rollformers are able to run panels 100’ or more that can be lifted by a crew. Some contractors even use a crane to elevate their portable rollformers and run out lengthy panels from roof level.

Reduced Transportation Costs

Eliminating the need to transport large panels to the site can reduce transportation costs. All that’s required is a trailer and truck to transport your portable machine and all the equipment and accessories that go with it. If something comes up, you don’t have to rely on available transportation to deliver additional panels. Plus, this eliminates the risk of freight damage which can hinder the on-time completion of projects.

On-Site Adaptability

Rollforming machines can be adjusted on-site to account for changes or unforeseen issues during construction, ensuring a precise fit. Also, you can run additional panels, if necessary, rather than having to re-order from a factory and possibly wait weeks for them to be delivered.

Reduced Delays

When you’re in control of the panel forming process, you’re not restricted by the manufacturing plant’s schedule, their issues with profile changes, transportation issues, and so forth. You’re not losing production hours with workers standing around waiting for a late delivery. Everything is done on-site, so you set your own schedule.

More Opportunities

With a portable rollformer, you can choose to run the machine on-site or in-plant. Not only can you run panels for your own installation jobs, but having your own machine allows you to form panels for other contractors. You can do chop-and-drops, which will bring in added revenue.

Greater Versatility

With some portable rollformers, like NTM’s SSQ II MultiPro Roof and Wall Panel Machine that runs 16 different profiles, you have more flexibility. You can purchase additional profile toolings as needed, and appeal to a wider range of consumers. Maybe you’ll expand your operations to include segments you hadn’t previously explored, like commercial building or board and batten siding and underdecking projects.

Portable Rollforming Machine Cons

Machine Cost

Owning a portable rollformer requires an investment. You have the cost of the machine, accessories, any upgrades (like notching or an advanced controller), and a trailer. All of this adds up to a substantial amount of money.

The other side to consider is your return on investment. You may have to do some calculating to figure out how much a portable rollformer can increase your profits and open up new revenue streams, such as chop-and-drop jobs. Chances are that the machine can pay for itself relatively quickly.

Job Site Time

Custom panel production from a portable rollforming machine requires more time on the job site, as you must load the coil, make any necessary profile adjustments, and run the panels. Most rollformers will work at speeds up to 60’-75’ per minute. Forming the panels will have to be calculated into your job site time. However, producing panels yourself still has advantages over ordering from a factory and waiting for production and delivery.

Skill-Dependent

Operators of rollforming machines require training and expertise to ensure panels are fabricated accurately. They need to know how to perform changeovers, make profile adjustments, form panels, and maintain the machine.

NTM strongly recommends rollformer machine training for you and your operators. At NTM, we offer free training to all new machine owners at our plant in Aurora, Colorado. We also offer on-site training for an additional fee.

Quality Control

Quality control for on-site production can be more challenging than in a controlled factory environment, leading to potential variations in panel quality. You may have to make adjustments to reduce uphill or downhill camber. Also, you’ll need to maintain your machine to keep it running smoothly and producing quality panels. This includes lubricating the shear and cleaning the rollers.

How to Know if a Portable Rollformer is Right for You

There is no question that owning a portable rollformer can save you time and money. However, it may also increase the amount of work you have to do prior to installation. Here are some factors to consider:

Your Workforce

You need to have a trained operator who can handle the machine. This means running panels, changing profiles, and making adjustments. The operator must also know how to care for the machine and what to do if something breaks down. As a business owner, you’ll want to ensure you have a dependable operator to run the machine.

Your budget

You don’t have to pay in full to own a rollforming machine. Financing is available. The place to start is by analyzing your budget and calculating payments into your revenue stream. You can also factor in the cost savings from fabricating your own panels as well as savings on transportation.

Workflow

Does your workflow justify purchasing a machine? If you’re a contractor who does occasional or part-time work, it may not be worth it to invest in a portable rollformer. Also, if you do small jobs that don’t require customization, maybe you don’t want the responsibility that comes with machine ownership.

However, if you have a steady workflow and regularly purchase factory panels, then a portable rollformer can save you time and money, and give you more control of your operation. You will no longer be at the mercy of plant and transportation schedules that cause delays and add costs to your business

Final Thoughts on Factory-Made vs. Portable Rollformer Panels

Choosing between prefabricated factory-made metal panels and custom-made panels from a portable rollforming machine depends on your business’s specific needs. Factory-made panels offer consistency, speed, and a wide variety of options, making them ideal for clients that don’t do a lot of metal roofing or wall panel projects, or have the crews to work with and maintain a portable machine. On the other hand, custom-made panels from rollforming machines provide unparalleled customization, cost-efficiency, and reduced transportation costs.

Ultimately, your decision should consider factors such as project sizes, workflow, customization requirements, budget, and timeline.

For information on NTM’s portable metal roof and wall panel machines, or our gutter machines, please contact us. One of our account managers can help you find the best fit for your operation.