Whether you’re buying your first portable roof panel machine and need to select a profile, or you’re unsure of what profiles you should add to your rollforming equipment, it can get complicated trying to figure out where to start. So, how do you pick a metal roof panel profile? What should you know about the project, your market, and other factors when selecting a profile?

At New Tech Machinery (NTM), we get asked questions like these all the time: “What panel profile do you recommend?” “What metal roofing profile is popular in my area?”

While we can’t tell you directly what profile to buy for your customer base or service area, we can help you find the information you need to make the best decision for your business and to serve your customers. Also, not every machine can produce the same profiles, so your choices may depend on what machine you have.

In this article, you’ll learn:

- What you need to know about your business and service area before choosing a profile

- How to find out which profiles you should consider based on your region and market

What Should You Know Before Choosing a Metal Roof Panel Profile for Your Service Area or Portable Rollformer?

Before requesting a quote on a portable rollforming machine, you need to decide which panel profile(s) you need. Also, if you’re looking to add more profile options for customers, it’s important to know what factors to consider.

What do you need to take into account before deciding on the profile or profiles you want to offer to your customers? Let’s look at a few of the factors:

What Metal Roof Panels Can Your Portable Rollforming Machine Produce?

If you are in the market to buy a roof panel machine, or if you already have one and just want to add profile options to expand your offerings, you first need to understand what profiles your machine can fabricate. If you’re purchasing and not sure what machine will meet your operational needs, take the Roof Panel Machine Quiz.

Not all roof panel machines produce the same profiles, so if you’re considering adding commercial options or wall / siding profiles, research which machines can produce those types of panels. Our SSR™ MultiPro Jr. and SSH™ MultiPro both run seven different profiles. Our flagship SSQ II™ MultiPro runs 16 roof and wall panel profiles, so is the most versatile. Our specialty machines, which include the WAV™ Wall Panel Machine, built for industrial use, runs four wall panel profiles. Our 5VC-5V Crimp™ Roof Panel Machine runs exposed fastener roof panels with three profile variations.

When you buy a new machine with New Tech Machinery, you get your choice of a profile roller set. If you’re trying to figure out which one to get, it helps to consider what would be the most bang for your buck and what will be the most requested by customers. Commercial profiles are the most expensive to purchase on their own, so if you bought the SSQ II™ MultiPro machine, you could select a commercial-style panel as your choice of profile.

How is your metal roofing business set up and how do you see it expanding?

Whether your business operates by supplying panels on site to metal roofing installers or by fabricating the panels and installing them yourself, it’s critical to understand where you see any possible future expansion of your services (i.e. branching out into commercial work, adding gutter installation services, etc.).

If you primarily install metal roofs yourself, you should have a good idea of what profiles you want to focus on and if you’d like to get into commercial projects eventually. If you want to get into “chop-and-drop” as a panel supplier, consider getting a machine that can make the profiles your customers would ask for.

What panel profiles are popular or specified in your region, market, and local building codes?

Understanding what kinds of standing seam panel profiles are popular or more often specified in your region will also help you pick the right ones for your portable rollformer.

Certain regions may also have local building codes (i.e. FM Approvals, Miami-Dade County, etc.) dictating which profiles you can use to adhere to their testing standards and the weather in certain regions. The current market demand in your area will also play a part in which profiles you will need to have on hand based on what’s popular with your customers.

Do you want to focus on residential metal roofing projects or eventually break into commercial work?

The scope of your current and/or potential commercial or residential projects can help guide your decision on which panel profile to use. Residential profiles are typically those with a 1.5” leg height or smaller. Once you get to a 1.75” seam height or taller, the panel profile is more structural and industrial-looking, and can be used on a lower slope for commercial projects.

What do the architect’s specifications dictate?

Before any construction or installation of a metal roof begins, the contracting company will receive the specifications and details of the project as dictated by the architect or engineer. This document includes details like what materials will be used, local building codes to adhere to, metal roofing accessories, and more. Knowing the structure and details of the project you’ll be working on will help you determine if you need to use a certain profile.

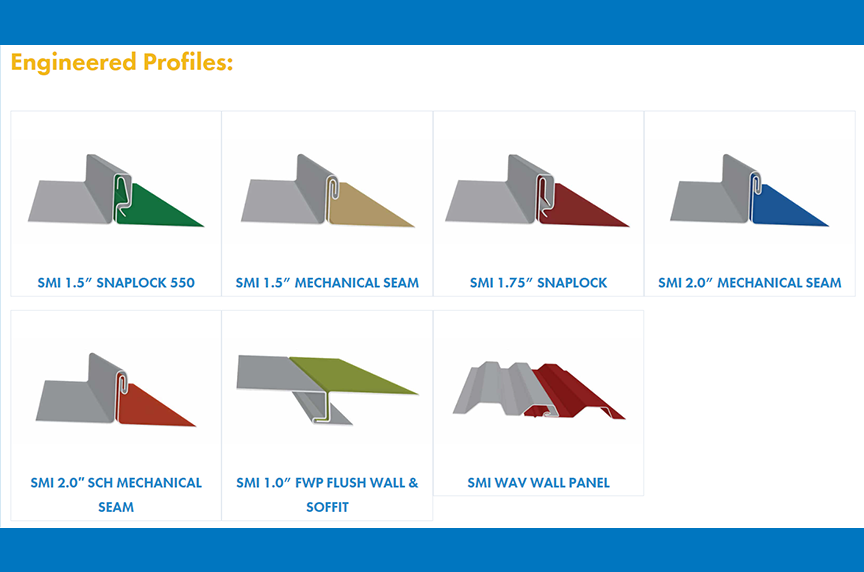

Do you need to use engineered roof panel profiles?

If the project you’ve bid on requires an engineered system, you’ll need to make sure you have or can purchase a profile tooling for your machine that meets those engineering standards (like wind uplift, water penetration, etc.).

Not all sizes or styles of profiles have engineering behind them. Although NTM doesn’t offer panel testing, you can check with your coil supplier to see what testing or engineering they offer for specific panel profiles. Some coil suppliers will be able to provide testing and engineering data if you are using their coil with your NTM machine.

How to Pick the Right Metal Roof Panel Profiles for Your Service Area & Portable Rollforming Machine

After you’ve done your initial research and understand some of the factors that can influence which profile you should choose, what are some ways you can find out the right profile to buy for your service area? How do you know which profile will be the right choice for your customers?

Here are some simple ideas to scope out the profile popularity in your region:

- If you have access, take a look at previous architectural bids and find out what specs, engineering requirements, and project scopes are common.

- Go out in your region and look at local metal roofing projects to see what profiles are popular or most often used in residential and commercial projects.

- Look at your competitors’ websites or talk to other roofing companies and find out what they offer in your area or comparable markets.

- Ask your local metal roofing coil or sheet supplier for their suggestions, what they are getting requests for, and what engineering they offer.

- Contact your local roofing associations or trade groups to ask other industry professionals and connect with other roofing contractors in your area.

Final Thoughts

Doing your research as a customer and buying the panel profiles you know your customers want in your area, can help ensure you’re making the right choices for your business. Remember, you can always buy other panel profiles as needed down the road, even if you don’t get them with the initial machine purchase.

Purchasing the right panel profiles for your area and customers has its benefits, including:

- You have the profiles your customer base wants in that region, residentially and/or commercially.

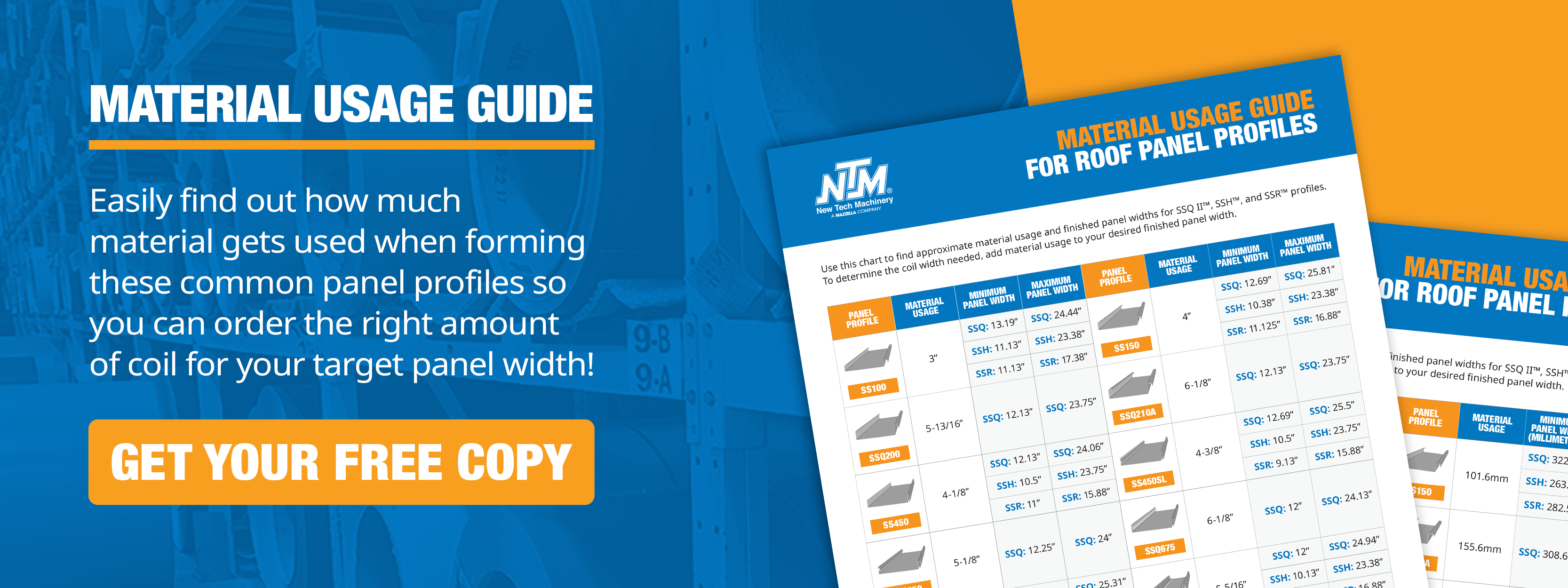

- You can order the right metal coil and source the right accessories (i.e. clips, fasteners, etc.) for that material and panel profile so it’s correctly installed.

- You’ll be able to adhere to building codes and engineering requirements by offering certain profiles.

- You’ll be able to bid competitively on metal roofing projects and know that you can meet the architect’s specifications.

- If you purchase a profile that you don’t end up liking or don’t see yourself using, it’s not easy to return or exchange that profile tooling with a manufacturer. It’s critical that you buy what you need, when you need it, to save yourself money and time.

After decades of making and selling portable rollformers, New Tech Machinery understands the importance of buying the right profiles the first time so your business can be as successful as possible. We’ve helped thousands of roofing contractors choose the right portable roof panel machine, accessories, and profiles to increase their product offerings and experience in the field.

Looking to get started with portable rollforming or want to find out more about our roof and wall panel profiles? Talk to one of our experienced rollforming specialists today!