Types of Metal Roof Profiles for Portable Rollforming Machines

Updated for 2025

There are lots of different models and manufacturers of portable roof panel rollforming machines, and each can make various metal roof panel profiles.

So, what’s the difference between snap-lock and mechanical seam? Or exposed fastener? And do you know which portable rollforming machines fabricate the profiles you’re looking for?

At New Tech Machinery (NTM), we know that your decision to get a portable roof panel machine involves a lot more than just checking out its features and specs. It’s important to know which profiles are available for the machine you’re considering and understand which materials you can run for that panel profile.

In this article, we’ll dive into the differences between different standing seam profile styles, what panel profiles we offer at New Tech, and which portable roof panel machines fabricate each profile.

If you’re unfamiliar with metal roofing or rollforming terms, check out our comprehensive Metal Roofing & Rollforming Glossary with definitions of words used often in these industries.

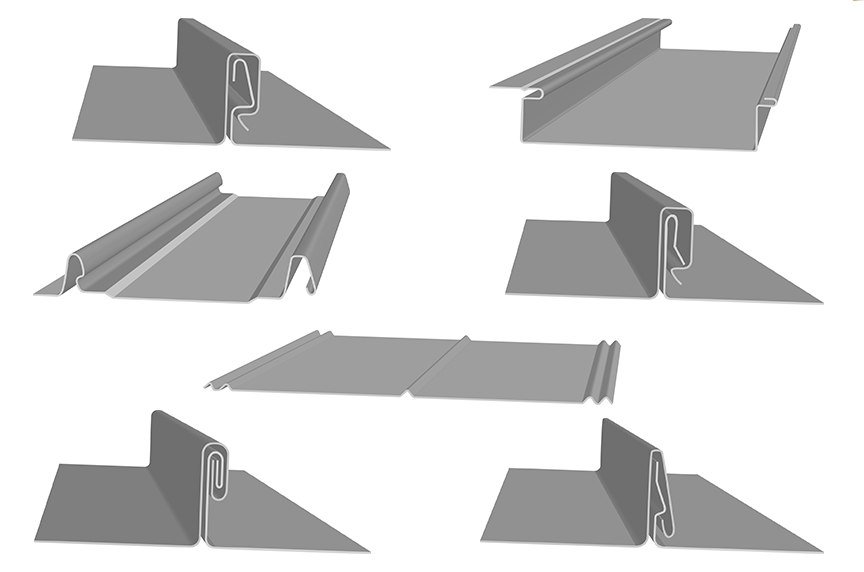

Types of Metal Roof Panel Profiles

Standing seam metal roofs are a type of concealed fastener metal panel system with vertical legs and a flat area between the legs. It’s a popular option for both metal roof and wall systems as the fasteners in this metal roof design aren’t visible and, as such, are protected from exposure to weather and the elements.

There are a variety of different panel profile styles, including:

- Snap-lock

- Mechanical Seam

- Fastener Flange

Other metal roofing profiles that may be available with your portable rollformer include:

- Flush Wall and Soffit

- Board and Batten

- Proprietary profiles specific to a certain manufacturer/distributor

For this article, we’ll only discuss the types of panel profiles available with New Tech Machinery roof panel machines.

Snap-lock Panel Profiles

Snap-lock panels are rollformed into shape with a male and female leg which snap together without using a hand or mechanical seamer during installation. They are typically used on roof slopes of 3:12 or greater unless otherwise specified by the manufacturer.

They are typically cheaper, faster, and require less labor to install. Once the seam is engaged, the panel is installed. You also don’t need to rent or purchase any seaming tools. Snap-lock profiles are a common choice for both commercial and residential building applications.

New Tech Machinery’s portable roof panel machines can manufacture a variety of snap-lock profiles, including:

SS450

Panel seam: 1 1/2” high

Panel material: Painted steel, painted aluminum, copper

Panel coverage: 12” to 24” on SSQII, 12” to 19 7/8” on SSH, and 11” to 15 7/8” on SSR

Machines that make this profile: SSQ II™ MultiPro Roof Panel Machine (SSQ II), SSH™ MultiPro Roof Panel Machine (SSH), and SSR™ MultiPro Jr. Roof Panel Machine (SSR)

SS450SL

Panel seam: 1 1/2” high

Panel material: Painted steel, painted aluminum, copper

Panel coverage: 12” to 24” on SSQII, 12” to 19 5/8” on SSH, and 11” to 15 5/8” on SSR

Machines that make this profile: SSQ II, SSH, and SSR

*Please note: the same roller set can produce either the SS450 or SS450SL profile; one just needs an extra roller to convert an SS450 profile to the SS450SL profile.

SSQ550

Panel seam: 1 1/2” high

Panel material: Painted steel, painted aluminum, copper

Panel coverage: 12” to 24”

Machine that makes this profile: SSQ II

SSQ675

Panel seam: 1 3/4” high

Panel material: Painted steel, painted aluminum, copper

Panel coverage: 12” to 24”

Machine that makes this profile: SSQ II

Both the SSQ550 and SSQ675 are also structural profiles capable of spanning open purlins, depending on the material you use and the finished panel’s width. Be sure to check what engineering is available for max purlin spacing.

Mechanical Seam Panel Profiles

Rollforming machines also make mechanical seam profiles, although this type of panel profile has vertical legs that line up together. Then, a hand or power seamer seams the panel legs, connecting the panels.

Mechanical seamed panels are typically stronger than snap-locks. However, the fact that they require seaming tools can make them more labor-intensive and costly to install. Some potential problems can come with using this type of profile, such as the seamer may jump and damage the seam.

One significant benefit of using mechanically seamed panels is that you can use it at a lower slope than snap-lock panels. Mechanically seamed panels are a great option if the roof slope is 2:12 or less unless otherwise dictated by the project specifications or panel design limitations.

NTM mechanical seam profiles include:

SS100

Panel seam: 1” high

Panel material: Painted steel, painted aluminum, copper

Panel coverage: 12” to 24” for SSQ, 12” to 21” for SSH, and 12” to 17” for SSR

Machines that make this profile: SSQ II, SSH, and SSR

SS150

Panel seam: 1 1/2” high

Panel material: Painted steel, painted aluminum, copper

Panel coverage: 12” to 24” for SSQ, 12” to 20” for SSH, and 11” to 16” for SSR

Machines that make this profile: SSQ II, SSH, and SSR

SSQ200

Panel seam: 2” high

Panel material: Painted steel, painted aluminum, copper

Panel coverage: 12 to 24”

Machine that makes this profile: SSQ II

SSQ210A

Panel seam: 2” high

Panel material: Painted steel, painted aluminum, copper

Panel coverage: 12 to 24”

Machine that makes this profile: SSQ II

*Both SSQ200 and SSQ210A profiles are made with the same roller set; one just needs an extra roller to convert from SSQ200 to SSQ210A.

The SSQ200 and SSQ210A are also structural profiles capable of spanning open purlins, depending on the material you use and the finished panel’s width. Be sure to check what engineering is available for max purlin spacing.

Fastener Flange Panel Profiles

Fastener flange profiles have similar characteristics to snap-lock profiles, except they are directly fastened to the roof deck through a flange on the panel’s male leg. Once fastened, the female leg snaps over the male leg. Because the fastener’s head is the only thing keeping the panels attached to the roof deck, it is not as strong as other snap-lock profiles that utilize clips to affix the panel to the roof deck.

This panel profile is typically used for higher slope applications, popular on residential buildings, and a cheaper standing seam profile option because you don’t need as many accessories to install them. They also don’t need clips for installation, saving time and money. It is recommended to run shorter lengths of panels when installing them due to oil canning or distortion from changing temperatures or expansion/contraction of metal.

Fastener flange profiles don’t always have engineered testing available, so they may not qualify for weathertight warranties. You’ll also need a substrate or decking on the roof to put the metal panels over.

At New Tech Machinery, we have these fastener flange profiles available:

FF100

Panel seam: 1” high

Panel material: Painted steel, painted aluminum, copper

Panel coverage: 12” to 24” for SSQ, 12” to 20” on SSH, and 11” to 16” on SSR

Machines that make this profile: SSQ II, SSH, and SSR

*Clip relief rollers are recommended with this profile to prevent potential fastener head distortion.

FF150

Panel seam: 1 1/2” high

Panel material: Painted steel, painted aluminum, copper

Panel coverage: 12” to 24” for SSQ, 12” to 18 11/16” on SSH, and 10” to 14 11/16” on SSR

Machines that make this profile: SSQ II, SSH, and SSR

*Clip relief rollers are recommended with this profile to prevent potential fastener head distortion.

Additional Popular NTM Roof Panel Profiles

Flush Wall & Soffit – FWQ100 and FWQ150

We have flush wall/soffit/underdecking panel profiles available with the SSQII Roof Panel Machine. As the name suggests, this panel profile’s seam lies flush with the wall instead of having legs as in other standing-seam profiles and is used as an architectural wall panel, soffit panel (with the optional perforations, you can have a vented soffit), or underdecking panel. It also offers an adjustable reveal from 0 to 3-inch increments.

Panel seam: FWQ100 is 1” high, FWQ150 is 1 1/2” high

Panel materials: Painted steel, painted aluminum, copper

Panel width: 12” to 22”; 25” maximum coverage with 3” reveal

Machine that makes this profile: SSQ II

Board and Batten – BBQ750

We have a board and batten wall siding profile for the SSQII Roof Panel Machine. This profile is only used for wall applications and is typically installed vertically. It gives a classic farmhouse look to any structure.

Panel materials: Steel and aluminum

Panel width: 10″ to 25″ coverage

Machine that makes this profile: SSQ II

Proprietary – SSQ275

At NTM, we also offer a specialty profile, the SSQ275, which can be snap-locked AND mechanically seamed. This specific profile offers added seam strength due to the snap-lock/seamed design and easy installation.

This proprietary panel combines technology from the 2” mechanical seam profile and the 1.75” snap-lock. This panel also includes testing and an installation and detail manual. Testing on this panel includes ASTM, UL, and FM.

Panel seam: 2” high

Panel material: 26 ga to 22 ga steel/painted steel or .024” to .040” aluminum/painted aluminum

Panel width: 12” to 24”

Machine that makes this profile: SSQ II

Trapezoidal – TRQ250

The trapezoidal panel profile is mechanically seamed with an anti-capillary leg. This structural profile is an excellent choice for both commercial and industrial building applications. Please note that there is no testing for this panel profile, but it is available.

Panel seam: 2 1/2” high

Panel material: 26 ga to 22 ga steel/painted steel or .024” to .040” aluminum/painted aluminum

Panel width: 14” to 24”

Machine that makes this profile: SSQ II

T-Panel

All of our profiles can produce a T-panel profile (a panel with straight up and down legs), except for the FF100, FF150, FWQ100, FWQ150, and TRQ250 profiles.

Panel seam: 1/2” to 2” (leg height is profile dependant)

Panel material: Painted steel, painted aluminum, copper

Machines that make this profile: SSQ II, SSH, and SSR

Last Take

We hope this article gives you a better idea of the differences between each of the profile styles and which ones are available with our rollforming machines. Many portable rollforming machines can produce panels in a variety of different profiles. However, it’s still important to know the differences between each profile and find the machine that will best suit your needs.

We strive to help our clients choose the best portable roof panel rollformer for their business, understand which profiles are available with specific machines, and provide quality post-sales support to ensure they get the most out of their machine.

If you are looking for assistance in choosing the right roof panel machine for your business or want to learn more about our portable rollforming machines and profiles, please reach out to our rollforming specialists.