NTM SSQ II MultiPro vs. Schlebach Quadro Plus

When choosing a machine for comparison to NTM’s flagship SSQ II MultiPro, the Quadro Plus, Schlebach’s top-of-the-line model, stood out because it was amongst the highest-quality machines on the market. Preference, however, is left to the consumer. This article is not intended to favor one over the other, but simply to compare the Quandro Plus to the SSQ II MultiPro. Both machine manufacturers have earned outstanding reputations in the industry and continue to produce robust, state-of-the-art rollformers.

While both the Schlebach Quadro Plus and the New Tech Machinery (NTM) MultiPro Roof and Wall Panel Machine rollformers fabricate similar roofing panels, in certain aspects the two machines operate differently. Schlebach and NTM designs contrast in ways not seen in other brand machines. We wanted to look at how the SSQ II MultiPro compared to a rollformer that wasn’t just another copy but unique in its design.

The Schlebach Company (Schlebach Maschinen GmbH), based in Germany, first released its QUADRO profiling machine in 1997. They have distribution partners worldwide, including Metalforming II Inc. in the U.S. Along with rollformers, Schlebach manufacturers folding/ seaming, bending, and specialized equipment.

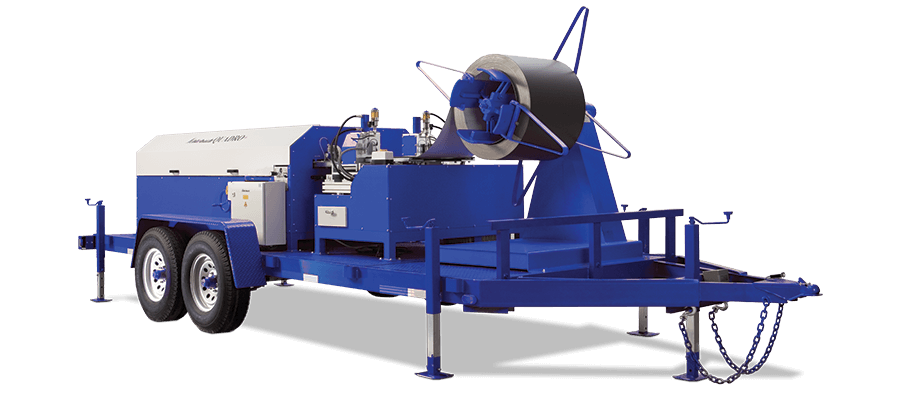

New Tech Machinery, based in Aurora, Colorado, built its first roof panel machine in 1991. NTM was the first company to commercially produce and market a polyurethane drive roller machine with separate forming rollers, which has now become the standard among most rollforming machine manufacturers. Along with its SSQ II, SSR, SSH and 5VC-5V Roof Panel Machine, NTM manufactures the WAV Wall Panel Machine and Mach II 5”, 6”, and 5”/6” Combo Gutter Machines.

In this article, we will deep dive into the following aspects of Schlebach’s Quadro Plus and NTM’s SSQ II MultiPro:

- Drive Systems

- Profiles

- Shear-cutting

- Auto-notching option

- Controllers

- Specs and Costs

Quadro Plus & SSQ II MultiPro Drive Systems

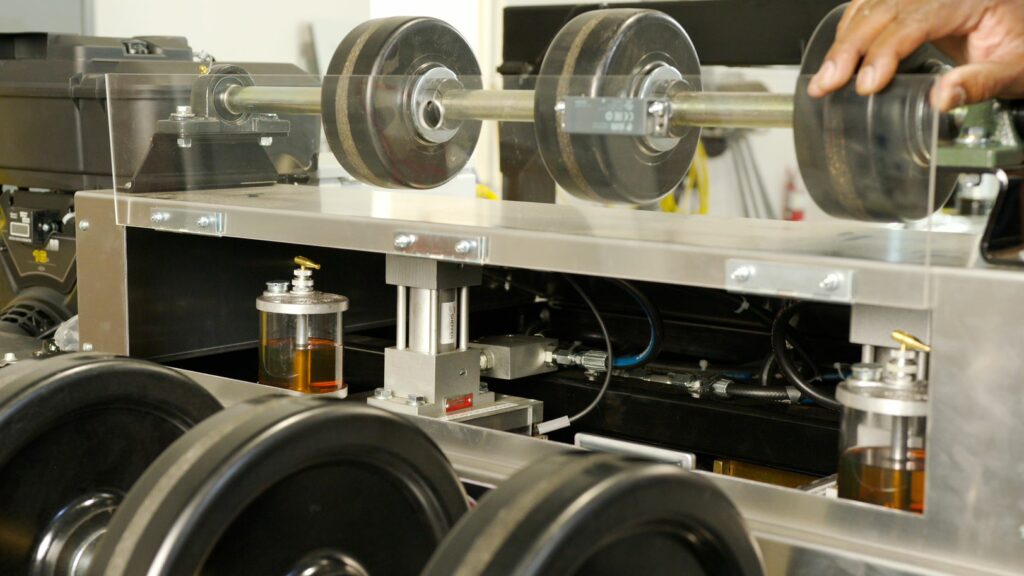

The Schlebach Quadro operates a unique hybrid drive system with dual drivelines built into the profile cartridge. The Quadro system was designed to eliminate oil canning, with the idea that the dual drive system would create less stress on the coil. The other aspect of this system worth noting is that it allows you to make tapered, double female and double male panels in two passes. Because of its design, it can produce narrower panels than would be standard in most cases.

The NTM SSQ II MultiPro has a single, center polyurethane drive system. The polyurethane drive system is designed to put less pressure on the coil as it moves it through the machine, as the single-drive system doesn’t pinch the edges of the coil. The polyurethane system also helps eliminate oil canning.

It’s probably fair to say that any oil canning caused by a machine can be corrected by adjusting the forming rollers, and shouldn’t be a prevelant issue with either style of drive system.

Quadro Plus & SSQ II MultiPro Profiles

The Schlebach Quadro Plus uses tooling cassettes that can hold two residential profiles. The cassette allows a quicker changeover as you just have to flip it and make a few minor adjustments. However, a forklift is required if you need to change cassettes, which isn’t always convenient if you’re out in the field. If you’re doing frequent changeovers between just two profiles, thought, this is definitely an advantage.

The NTM SSQ II MultiPro offers 16 quick-change profiles that a single person can change in less than an hour. No need for a forklift, so while it may take a bit more time for the changeover than with the Schlebach Quadro, it’s more convenient out in the field.

Both machines can run standing seam and metal wall panels.

| Quadro Plus Profiles |

|---|

| 1″/ and 1.5″ Snap Seam |

| 1″ and 1.5″ Nail Strip |

| 1″ and 1.5″ Mechanical |

| 1″ and 1.5″ U-Panel |

| 2″ Mechanical |

| 1″ Soffit (no reveal and max reveal) |

| 1.75″ Snap Seam |

| Board & Batten Panel Profile 1.75″ Snap Lock (dedicated cassette) |

| Soffit/ Wall Profile-Flush up to 1″ reveal (dedicated cassette) |

| SSQ II MultiPro Profiles |

| 1″, 1.5″, and 2″ Mechanical |

| 2″ ARMCO Mechanical Seam |

| 1.5″ and 1.75″ Snap Lock |

| 1″ and 1.5″ Snap-Lock with slotted flange |

| 2.5″ Mechanical Seam Trapezoid |

| 2″ Snap-Lock/ Mechanically Seamed Proprietary profile |

| 1.5″ 550 Snap Lock |

| 1″ Flush wall/ soffit/ underdeck panel with adjustable reveal |

| 1.5″ Flush Wall |

| T-Panel |

| Board & Batten |

Shear Cutting Functions

The Quadro Plus is unique in that the shear cuts from the entry point. In contrast, the SSQ II MultiPro shear cuts from the exit point. There are advantages and disadvantages to both.

Advantages to pre-cut include creating a clean cut and allowing the user to hand-feed for low-volume production. Also, pre-cut shears require less maintenance. No die changes are needed for varying profiles because cutting is done prior to rollforming.

However, some panels run better on post-cut, like high-strength and heavy gauge steels. Also, shorter panels can’t be run with pre-cut shears, whereas post-cut can handle as short as 3″ or 4″ panels.

The main disadvantage to post-cut is the high maintenance. The shear, as mentioned, needs constant lubrication. Then there’s the expense and maintenance of cut-off dies.

Ultimately, most panels can be produced using either shear. Though the post-cut end may look a bit rougher, it’s worth noting that this edge gets tucked under, so it’s debatable whether it makes much difference. While the pre-cut may be more cost-effective and provide a cleaner cut, it isn’t ideal for every situation. Many contractors prefer the post-cut for this reason.

One feature on the shear end of the SSQ II is the proximity sensor. The proximity sensor pauses machine operation if a panel hasn’t been removed once it moves past the shear. That way, the panel doesn’t get damaged or scratched by being pushed out, as the machine will run at the pace of the operator. Once the panel’s been removed, the machine will resume the sequence. The SSQ II is the only machine on the market with this feature.

Quadro vs. SSQ II Auto-notching

Both the Quadro Plus and the SSQ II MultiPro offer auto-notching as an option. Both work using hydraulic systems to notch the panels. Also, both can produce offset notching on panels and can combine with angle cutters, offered by each company as additional options.

The difference here is that with the Quadro Plus, the notcher is a separate unit that attaches to the machine. In the SSQ II, the notching system is built into the machine. The SSQ II has an advantage, especially in terms of transportability, as you don’t have another piece of equipment needing to be attached as an accessory and moved separately. It’s all-in-one machine.

Sieman Touch vs. UNIQ™ Controller

Both machines offer advanced controllers and software.

The Quadro Plus includes a Siemens Touch Screen controller batch control system. Users can program jobs directly into the controller. The machine can be run fully automated or in fully manual control mode.

NTM’s SSQ II MultiPro offers the UNIQ Automatic Control System as an added option. The UNIQ controller also has a USB port and the ability to upload or download a cutlist. It features a coil calculator for estimating the amount of material you have, job and entry functions, and machine settings. You can program notching, including angled notching for hips/ valleys, etc. The USB port makes program updates easy and allows you to import a 600-panel length cut list and export final project specifications. The UNIQ Controller allows you to tell the SSQ II the exact length and quantity of the panels, and controls the machine’s drive and shear.

Quadro Plus vs. SSQ II MultiPro Specifications

| Quadro Plus | |

|---|---|

| Length | 132″ |

| Height | 50″ |

| Width | 60″ |

| Weights | |

| Quadro with Cassette | 3,500 lbs. |

| Cassette weight | ~600 lbs. |

| Speed | Up to 70’/ min. |

| Power | 230 v, 1 phase, 60 hz electric motor |

| Finished Panel Widths | 8″-24.5″ |

| SSQ II MultiPro | |

|---|---|

| Length | 172″ |

| Height | 30″ |

| Width | 62″ |

| Weight (with roller set) | 2,830 lbs. |

| Speed | Up to 75’/ min. |

| Power | 7.5 HP, 3 phase, 5 HP, 1 phase and/ or Gas Power (16 HP Briggs & Stratton Engine) |

| Finished Panel Widths | 12″ to 24″ (depending on profile) |

| Materials | |

| Steel | 22 ga. |

| Aluminum | .032″ |

| Copper | 20 oz |

| Zinc | .032″ |

| Materials | |

| Painted Steel | 28 ga. to 22 ga. |

| Painted Aluminum | .027″ to .040″ |

| Copper | 16 oz. to 20 oz. |

| Terne Coat Stainless | 26″ ga. |

Training Costs

Training is required for the Quadro Plus on-site or in-house by a MetalForming technician to validate the machine warranty. On-site training is $185 per hour plus travel expenses and incidentals. In-house training is available to customers willing to travel to Peachtree, Georgia, also for $185 per hour.

New Tech Machinery does not require training to validate the machine warranty, but training is highly recommended, especially for the SSQ II with notching. On-site training is $750 per day, plus trainer travel expenses and incidentals. In-house training is available to customers at the main plant in Aurora, Colorado, free of charge for new machine owners.

Last Take on Quadro Plus vs. SSQ II MultiPro

As stated at the beginning of the article, both the Quadro Plus and SSQ II represent the finest in portable rollformers. User preference may be the ultimate determining factor.

The Quadro Plus’s quick-change cassettes make profile changeovers fast and enable flipping between two residential profiles very easy. Commercial profiles are dedicated to a single cassette. Also, cassette changeovers require a forklift. On the other hand, the SSQ II profile changeover takes less than an hour and can be performed in the field with a single operator.

If you’re operating the machine strictly in-plant, either will do the job. However, some of the SSQ II’s features, like the built-in notching and gas engine options and overhead coil arbors render it more transportable as you don’t have a separate generator and notching unit.

For information on the SSQ II MultiPro Roof and Wall Panel Machine, or any of our machines or accessories, feel free to contact us. One of our account managers will be happy to answer any questions you may have.