Best Accessories for the SSQ II, SSH, and SSR Panel Machines

How important is choosing the right accessories when purchasing an NTM portable panel machine?

Truth be told, investing in a New Tech Machinery (NTM) portable roof panel rollformer is no small matter. If you’re already in the metal roofing industry and you’ve been buying from a supplier, then chances are, you’re going to increase your profits and pay off the machine in a relatively short order.

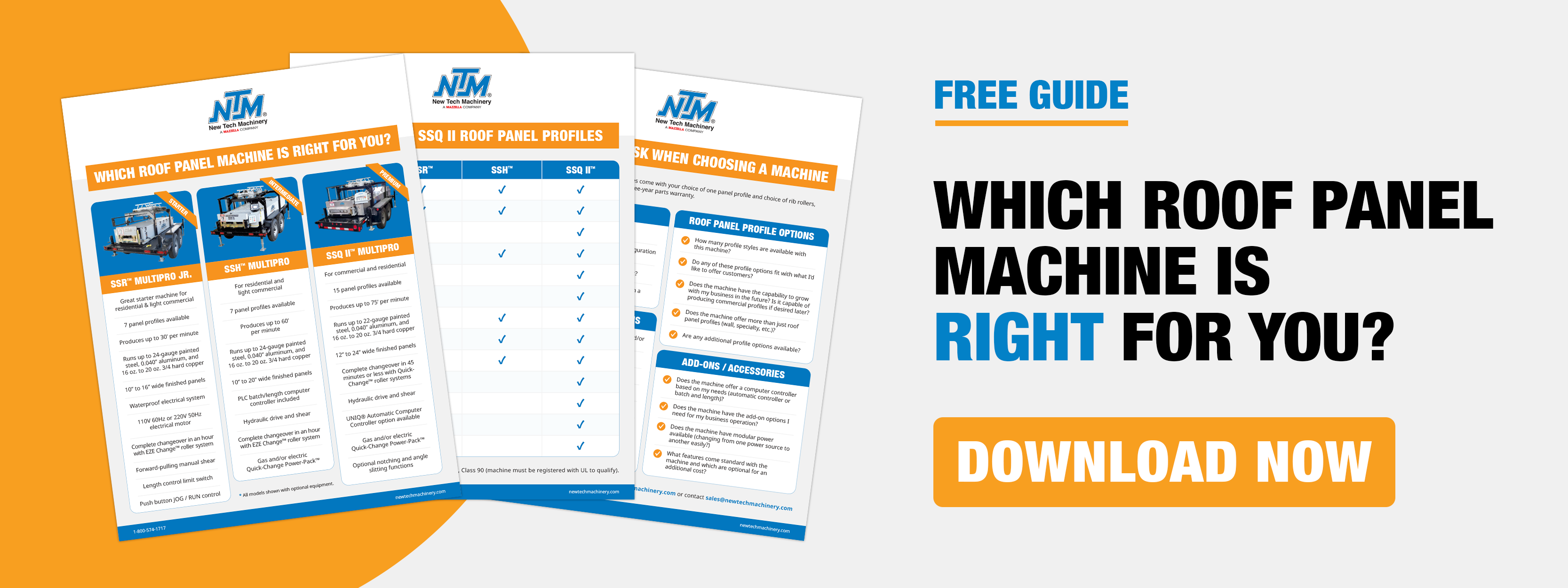

For metal roofing contractors new to the game, their NTM rollforming machine will serve as the foundation of their business. Whether you’re looking at the SSQ II™ MultiPro, the SSH™ MultiPro, or the SSR™ MultiPro Jr., you want to make sure you get the best performance—and that can come down to choosing the right accessories.

Below, we’ll cover which add-ons you really need, why they’re useful, and how easy they are to add (or “retrofit”) if you don’t buy them right away, or if you currently own an NTM panel machine and need an add-on. We’ll also cover the list prices of each one.

Meet the Machines: SSQ II, SSH, & SSR

SSQ II MultiPro Roof and Wall Panel Machine

Our flagship portable rollformer runs up to 16 metal roof and wall panel profiles (and also offers optional notching and angle-slitting functions) and can be powered by a gas engine or electric motor. Prices with one profile, trailer, and basic accessories run from $115,000 – $130,000. Packages are also available, which offer popular options to the price of the machine at a reduced price-point.

SSH MultiPro Roof Panel Machine

Runs seven standing seam profiles, with the PLC computer batch/ length controller included as standard. Base price starts around $65,890 with one profile—you’ll see many setups around $94,000.

SSR MultiPro Jr. Roof Panel Machine

Our most budget-friendly option, used primarily for residential jobs. Starts at $41,200 but can go to $68,000+ if you fully outfit it. Also runs seven standing seam profiles.

All three are multi-profile capable, and purchased added profiles can be swapped out with our Quick-change tooling. However, not all profiles are compatible with all machines.

Coil Handling Accessories

Why They’re Important

You can’t form panels without feeding your coil into the machine, and you need the right equipment to do it safely and efficiently.

Top Coil Handling Options

Dual Overhead Reel Stand

- Compatibility: Optional add-on for SSQ II and SSH, already standard on the SSR.

- What It Does: Holds up to two coils above the machine (up to 3,000 lbs. each). Great if you want to switch between different colors or gauges quickly, or are handling a large job.

- Retrofit? Sure, you can add it later if you start with a free-standing decoiler.

Free-Standing Decoiler

- Compatibility: Works with all three machines—perfect for an in-plant setup.

- What It Does: Sits on the floor to hold coils up to 5,000 lbs, feeding your machine from the rear.

- Retrofit? Yes. If you decide to go in-plant after using a trailer, or you need heavier coils, you can add one later.

Expandable Arbors

- Compatibility: One size fits all (SSQ II, SSH, SSR).

- What They Do: Slide into the coil’s core, expanding to lock it in place.

- Pricing: $2,570 each.

- Retrofit? Easily. You might start with one arbor and add a second if you want to keep multiple coils ready to go.

Controllers & Automation

Why They’re Important

An NTM controller provides more accurate panel lengths, less waste, and easier operation. You’ll also have the option to automate certain features like notching or hot-melt sealant applications.

Controller Options

- Manual Controls (Limit Switch)

- Standard on all three machines.

- Basic but does the job if you run shorter panel batches.

PLC Controller

- Standard on the SSH, but not an option on the SSR.

- Program your panel lengths and batch runs for more precision and productivity.

UNIQ® Automatic Control System

- For SSQ II.

- Higher-end touchscreen controller with advanced diagnostics, best for shops that need to run complex projects and is required for notching and angle-slitting options.

EZ-Counter (SSR)

- Great upgrade if you start out with the SSR’s standard limit switch but end up needing more accurate lengths than what a limit switch offers, saving material and time.

- List price: $3,100.

Retrofit Notes

Yes, you can upgrade most controllers after you buy the machine. However, notching only works on the SSQ II with the UNIQ controller. Also, notching cannot be added to an existing SSQ. In addition, angle cutting is only available on SSQII machines that perform notching.

Run-Out Tables

Why They’re Important

Run-out tables catch and support formed panels so they don’t fall, bend, or get scratched.

Features & Costs

- Standard: The SSR Jr. includes 20 feet of run-out tables (two 10-foot sections).

- Optional: SSQ II and SSH users can add as many 10-foot sections as they like ($580 – $950 per section, depending on the machine model). Up to five run-out tables fit on the reel rack for transport and storage.

- Retrofit? Yes, they bolt right onto each other. If you start running longer panels, you can always add more sections later.

Pro Tip: Even if you’re doing short panels, at least one 10-foot section is a smart buy. It helps you run panels solo, prevents floor damage, and keeps your panels pristine and level.

Trailers & Carts

Why They’re Important

These machines are portable—if you plan to fabricate panels directly at job sites, you’ll need a trailer. If you’re running panels strictly in-shop, a cart might do the trick.

NTM 12,000 lb. Tandem-Axle Trailer

- Works for the SSQ II, SSH, and SSR.

- Fully equipped 12,000 lb. capacity trailer with electronic brakes, a breakaway kit, 4 independent jack stands, and crane lifting eyes on each corner of the trailer. Also, our trailers now have scrap trays to catch the metal tailings when panels are sheared.

- List price–$18k.

- Retrofit? You can buy the machine now and add the trailer later. It’s a little work (you’ll need a crane or forklift), but totally doable. However, you want your machine on a cart. Don’t keep it on a wooden pallet. NTM trailers are NATM (National Association of Trailer Manufacturers) compliant. This means they measure up to industry safety standards.

In-Plant Carts

Stationary or Mobile Carts

- Ideal for factory setups, if you don’t plan to leave your facility.

- Pair well with free-standing decoilers. Feature mount feet and casters (the carts are not designed to support the weight of the machine with dual overhead reel racks, so free-standing decoilers must be used instead).

- Retrofit? Switching from a cart to a trailer later is also possible, just more lifting logistics.

- List price: $6,400 – $7,300

Covers & Protective Gear

Why They’re Important

Keep your rollformer clean, dry, and protected from the elements or debris. A good cover can save you big headaches from rust, dust, dirt, and debris, or electrical damage.

Machine-Specific Fitted Covers

- Available for SSQ II, SSH, and SSR.

- Built from K-Tex heavy-duty boat-cover style synthetic canvas material. Specially fitted to the machine.

- Prices range $2,850–$3,350.

- Retrofit? There’s nothing to “install.” You just buy it and drape it on—easy to add any time.

Notching, Hot Melt, & Other Upgrades

Notching & Angle Slitting (SSQ II Only)

- Perfect for: Complex hips, ridges, or panels needing factory-finished notches.

- Requires: UNIQ controller.

- Retrofit? For notching, no. It must be purchased pre-production and cannot be added to existing SSQ machines. Angle slitting can be added as it attaches to the exit end of the SSQ.

- List price for notching: SSQ with notching: $135k. Includes one panel profile of the customer’s choice. Requires UNIQ controller (lists for $20,700).

- List price for angle slitting: $10,100

Hot Melt Pump Interface (SSQ II & SSH)

- Great for: Low-slope metal roofs needing internal seam sealant.

- Retrofit? Yes. You buy the interface from NTM, and the actual hot melt system from Hot Melt Technologies, an outside vendor.

- List price: $950 – $1,325

Extra Rib Rollers & Hand Seamers

- Rib Rollers: Add pencil ribs, striations, or beads to panels. NTM recommends purchasing the rib roller frame for each tooling set. This saves labor and is easier to store. Typical cost is $950+.

- Hand Seamers: Handy for manually closing seams on mechanical-lock panels.

- Pricing: Single lock, $525. Second-stage $775

- Retrofit? Absolutely. Most folks pick these up as needed for particular profiles or job specs.

How Important Are Accessories?

Choosing NTM machine accessories isn’t like opting for leather seats in a new sedan. Having the right accessories is vital, as they can make your operation a whole lot easier—and your jobs more profitable. From controllers that automate batch cutting to reel stands that speed up coil changes, these add-ons help you make the most of your investment. The good news is that most of these accessories can be retrofitted, so you can start simple and scale up as your business needs grow.

For more details and current pricing, check out the New Tech Machinery Learning Center or browse the Product Pages for each machine. You can also find more accessory guidance and detailed machine pricing in these articles:

- What is the ROI On a Portable Roof Panel Machine?

- The Best Accessories for the SSR MultiPro Jr. Rollformer

- Portable Roof Panel Rollforming Machine Cost

Whatever machine you go with—SSQ II, SSH, or SSR—remember that genuine NTM accessories will keep your equipment running at its best.

Whether you’re brand-new to metal roofing or expanding your current operation, we can help you pick the right machine and accessories for your projects. Contact us to speak to one of our knowledgeable account managers.