NTM’s SSH MultiPro vs. SSQ II MultiPro Roof Panel Machines

If you’re looking at purchasing one of New Tech Machinery’s (NTM) roof panel machines for your business, you’re probably wondering if the SSH™ MultiPro Roof Panel Machine is adequate for your workload or if you’re better off going with the SSQ II™ MultiPro Roof and Wall Panel Machine. It’s a question we frequently get from our customers. There’s no simple answer, as while both are great machines, you may find one fits your needs better than the other.

You can tell from the starting price that the larger SSQ II is going to give you more options. There’s no question that the SSQ II is NTM’s flagship model, and we sell more SSQ IIs than any other machine we produce. That said, not everyone needs the broad profile range of an SSQ II. The SSH MultiPro is a fine machine, offering contractors many profile and material options.

This article will closely compare these two machines to what best matches your operation. We’ll look at:

- Specifications

- Profiles

- Options

- Materials and widths

- Pricing

- Owners

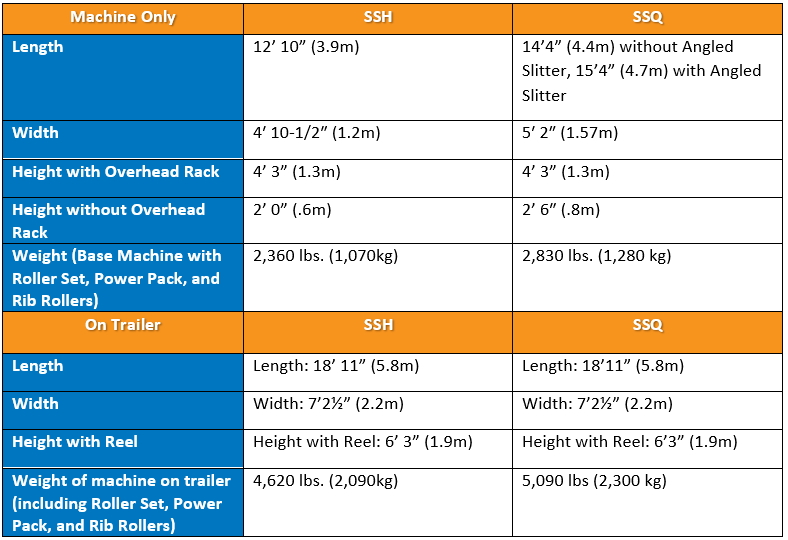

SSH and SSQ II Specifications

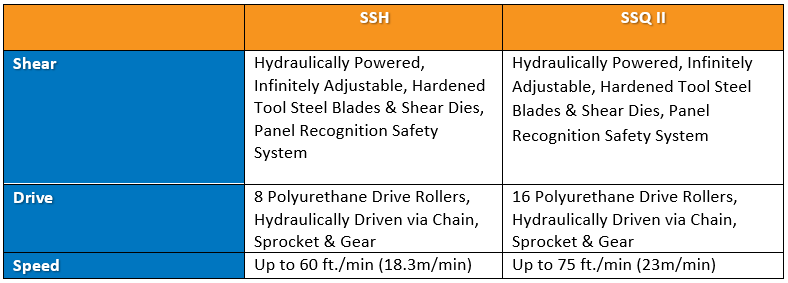

The two roof panel machines exhibit some differences in their mechanics. For example, while they’re both hydraulically driven via chain, sprocket, and gear, the SSH is chain driven with eight drive rollers to operate the drive system, whereas the SSQ II is gear driven and uses 16 drive rollers. Additionally, the SSH uses three carriages for tooling alignment whereas the SSQ II uses the width adjustment. Both require about the same amount of maintenance.

The key is to keep your machine well-maintained so that you don’t put unnecessary wear and tear on parts. Because the SSQ II is larger does not necessarily mean that it incurs more maintenance costs. The need for repair is related more to how well you care for your machine. Also, improper use can risk voiding your warranty.

SSH and SSQ II Profile Options

SSH profiles include most of the same roof profiles as the SSQ II, but are limited to 1 ½” height, which is generally adequate for residential and light commercial use. One significant difference is the SSQ II Machine can produce a 1” or 1 ½” wall or soffit, and specialty panel profiles like the board & batten that the SSH can’t produce.

If your business is strictly residential and light commercial roofing and you’re not looking to expand into heavier commercial work or metal siding, then the added profiles won’t prove advantageous.

It’s also worth noting that with the SSQ II, the Quick-change profiles take less time to change—only about 45 minutes. The SSH profile changeover is more time-consuming, taking 1-2 hours, depending on your familiarity with the changeover process. If you’re working with a tight schedule that requires profile changeovers between jobs, this issue is something to consider.

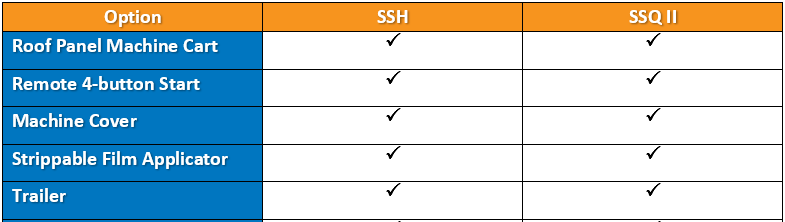

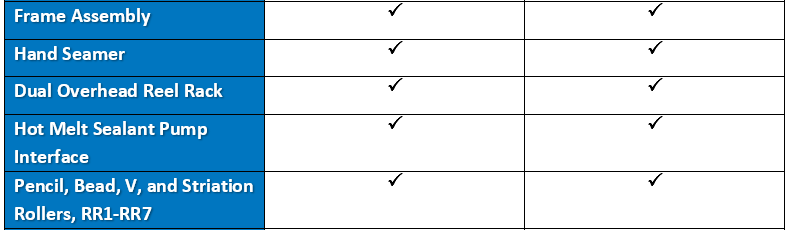

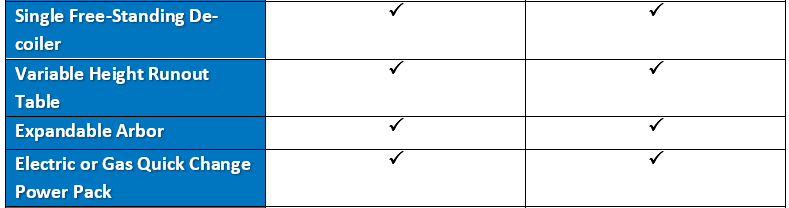

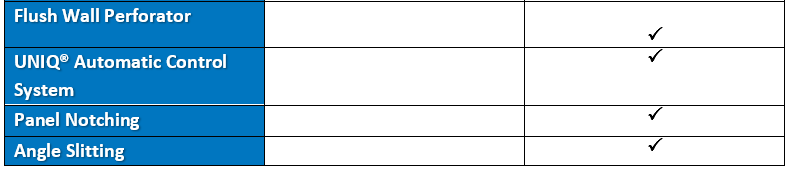

Add-On Options

Both machines offer options at additional costs. Check the chart below for the full list of options. Notable SSQ II options not available for the SSH include the following:

UNIQ® Automatic Control System

The UNIQ Automatic Control System is NTM’s most advanced controller. It includes:

- 7” touchscreen with troubleshooting screens

- Coil calculator, controller settings, length calibration, and more

- USB port to import a 600-panel length cutlist and export final project specifications

- Interactive pop-up error messages for easy troubleshooting

- Controls shear and notching accessories (sold separately)

Panel Notching

Built into the machine, the hydraulic notching system punches notches before the legs are formed for a clean cut. Finished panel has a 1” (25.4mm) wide strip at each end for hemming. Notches can be offset for angled cuts. Snap-seam panels can be made with a profiled flap to be used as a closure. The UNIQ Automatic Controller is required to operate the notching system at an additional price.

Angle Slitting

The angle slitter attaches to the exit end of the SSQ II. It slits at any angle from 90° to 35° for panels up to 24” (610mm) wide.

SSH and SSQ II Materials, Panel and Coil Widths

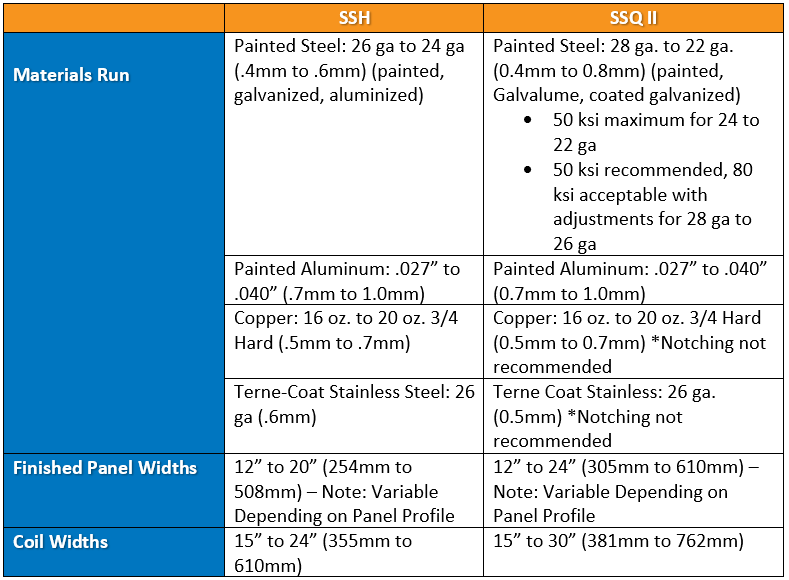

The SSH has eight polyurethane drive rollers which will run the 26 or 24-gauge steel and finished panel widths of 12” to 20”. The SSQ’s 16 polyurethane drive rollers can handle thicker 22-gauge steel and finished panel widths of up to 24”.

SSH and SSQ II Pricing

Price is a major factor for many buyers, especially those new to the business. The SSH starts at $65,890 and includes a profile set, while the SSQ II starts at $63,400 but profile sets are sold separately, so the difference is significant when you consider that you’ll need to purchase a trailer and necessary accessories. That said, other factors should be weighed into the buying decision. The SSH comes standard with the PLC batch and length controller that allows users to program these features into the machine for automatic panel production. While not as advanced as the UNIQ controller it’s a very handy feature, simplifying the machine’s operation.

Depending on the size of the jobs and your workflow, the machines can pay for themselves relatively quickly. Also, they also have a high resale value (you won’t find many used NTM machines on the market, and they’re known to last a long time with proper care). So, you could say you won’t experience high depreciation in your machine, especially if you maintain it.

Many first-time buyers are drawn to the SSH due to its lower price. If you don’t plan to move beyond residential and light commercial roofing, then it makes sense. However, if you’re considering expanding into commercial, large-scale residential, or wall panels, even a few years down the road, think about this: Is it cheaper to buy the SSH now and purchase an SSQ II in two or three years, or get the SSQ II which will be able to handle the growing workload as you expand?

Over the years, we have had SSH owners whose businesses never really changed and who remained happy with their purchases. We have also had SSH owners who wished they’d purchased the SSQ II from the get-go because as it turned out, their businesses did expand and they needed the options offered by the larger machine. Remember, this is a machine that, assuming you take proper care of it, will last you decades. We have machine owners who’ve had their machines since NTM’s early days in the 1990s when we built the SSQ’s predecessor, the SSP. Many of these machines are still running!

The bottom line is, if you plan to grow your business, the SSQ II MultiPro can support your development as a metal roof and wall panel contractor. We like to think that the SSQ II develops as you develop. It has so many features and capabilities that few users reach the end of its potential. Our customers sometimes expand their operations, and the SSQ II accommodates the increasing work demands and offers them the flexibility to run a wider variety of panel profiles.

SSH and SSQ II Owners

The Ideal SSH Owner

- Small roofing operations or part-time contractors

- Residential panel work by job (running panels on-site)

- Small to medium-scale chop-and-drop operation (running panels on-site)

- Small to medium scale residential or light commercial projects

- Operations not planning to expand beyond residential and light commercial roofing

The Ideal SSQ II Owner

The SSQ II MultiPro Roof and Wall Panel Machine is ideal for businesses operating on commercial or large-scale residential projects.

The SSQ II is a good fit for the following work:

- Finished panel work producing panels for installers (running panels in-plant)

- End-user production and installation

- Large-scale chop-and-drop operation (running panels on-site)

- Large residential projects

- Commercial jobs

- Residential or light commercial operations planning to expand to wall panel and/ or commercial markets

Final Thoughts on the SSH vs. SSQ II

The higher production speed, thicker gauge steel, wider panels, taller seams, and greater number of profiles offered by the SSQ II are not necessary for the operator who runs a small to medium size residential to light commercial operation. However, businesses planning for future growth may be wise to invest in the SSQ II to accommodate a wider range of profiles.

If you’re still not sure of your direction, talk to a contractor who’s been in the business for a while. They’ll likely be happy to pass along wisdom they’ve collected over their years in the industry. Chances are, they started out the same as you.

You can also speak to one of our machine experts. At NTM, we’ve been helping metal roofing, wall panel, and gutter contractors for decades. Our business is to help you grow yours, so give us a call.