How NTM Machine Owners Benefit From Sheffield Metals

by Colin Murnan and Rick Zand

New Tech Machinery (NTM) and Sheffield Metals International (SMI) are sister companies, which is why SMI products align so well with NTM portable rollformers. However, NTM machine owners may not know about the benefits of using SMI for their coil needs in engineering, testing, machine support, and more.

We liken the relationship between NTM and SMI to a stapler and staples, where an NTM machine acts as a stapler and SMI provides what the machine/stapler needs to do its job. But the relationship goes further than this, as NTM machine owners benefit from more than SMI’s high-quality metals and warranties.

In this article, we’ll show you the practical advantages of sourcing coil from SMI specifically for NTM portable metal panel machines.

You’ll discover:

1) SMI Coil Engineered for Portable Rollforming

- Tight thickness tolerances: Consistent gauge across the coil helps maintain panel width, rib height, and finished profile fit-up—critical for avoiding oil-canning, poor engagement, or panel drift.

- Optimized formability: SMI metal bends cleanly on portable rollforming machines to minimize paint cracking in tight bends like snap-lock seams, ribs, and hems.

- Clean edges and coil handling: Proper slit edges and coil winding reduce feed issues, edge wave, or camber that can cause tracking problems through NTM tooling.

What it means for you: Fewer adjustments, fewer scrap panels, and more time spent installing—not fiddling with entry guides and depth settings.

2) Proven SMI Coatings That Run Well and Look Great

- PVDF systems: Premium fade and chalk resistance for standing seam roofs and walls. PVDF paints hold up in demanding climates and maintain curb appeal.

- Over 50 color choices: Access to architectural colors that align with spec requirements, HOA preferences, and regional styles—helping you win bids without special-order delays.

What it means for you: A better-looking finished panel with durable color performance—and fewer warranty callbacks related to finish.

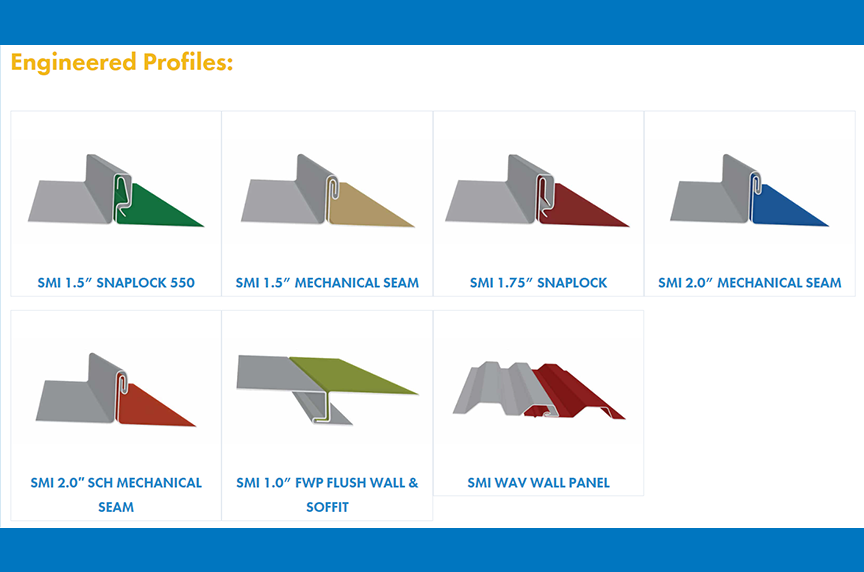

3) SMI Compatibility With NTM Profiles and Tooling Best Practices

- Field-proven performance: Contractors across North America run the SMI coil through NTM SSQ II™, SSR™, SSH™, WAV™, and the 5V-5VC™ Crimp, which has been tested specifically for most NTM panel profiles.

- Profile-specific recommendations: SMI’s team can advise on coil width, gauge, and substrate for the NTM profile you’re running (snap-lock vs. mechanical seam, etc.).

- Accessory alignment: Coil specs that integrate cleanly with common underlayments, clips, sealants, and trim stock to ensure the entire system performs as designed.

What it means for you: You have the SMI team who are familiar with your machine and profiles and can facilitate matching the right type and gauge of metal with the best coatings and substrates to your project profiles and specs.

4) SMI Substrate Options Built Around Performance and Budget

- Galvalume® (AZ50/AZ55), G-90 galvanized, and aluminum: Choose corrosion resistance to match coastal, industrial, or high-snow-load environments.

- Common gauges for NTM: 0.019–0.032 aluminum; 24–26 ga steel are readily available—no guessing if your machine will run it well.

What it means for you: The right material for the environment—and peace of mind that it will run well in your NTM.

5) SMI Warranties That Protect You and Your Customer

- Finish and substrate warranties: SMI’s PVDF and SMP paint systems and metal substrates come with established warranty programs that architects and building owners expect.

- Clear documentation: Straightforward warranty terms help you set expectations with customers and protect yourself from ambiguous claims.

What it means for you: Confidence in selling higher-end roofs with the paperwork to back it up.

6) SMI’s Consistent Supply and Logistics Support

- Strategic stocking: SMI maintains inventory in popular colors, substrates, and gauges to shorten lead times for crews on the go.

- Slitting and packaging for jobsite rollforming: Packaged for safe transport and fast deployment, with attention to coil OD, ID, and weight that fits your decoilers and trailers.

- Multi-location distribution: Reduced freight distances mean quicker turns and less downtime.

What it means for you: Keep your crew rolling—fewer schedule slips waiting on material.

7) Technical Support From a Team That Knows NTM Machines

- Real humans, real answers: SMI technical specialists understand rollforming, panel geometry, and how small coil variances affect output.

- Troubleshooting partnership: If you see rib waviness, panel twist, or seamer challenges, SMI can help you isolate whether the cause is coil, entry guides, or tooling alignment.

- Training resources: Guidance on storage, handling, and job-site best practices to prevent damage before the coil ever reaches the machine.

What it means for you: Faster root-cause fixes and better productivity in the field.

8) SMI Quality Control in the Finished Panel

- Incoming metal verification: Substrate, coating weight, and paint system checks provide consistency from coil to coil.

- Documented tolerances: Targeted gauge and width tolerances support accurate profile geometry and watertight seams.

- Batch traceability: If there’s a problem, SMI can track it and act quickly.

What it means for you: Repeatable panels that install faster and seal better.

9) Total System Value: Lower Rework, Higher Margins

- Quality assurance: Good coil helps you avoid micro-cracking at tight bends and feeding defects that produce out-of-spec panels. With weathertight warranties offered for commercial projects, your customers can be reassured of the quality and durability Sheffield Metals provides.

- Sheffield Metals’ testing is based on NTM panel profiles, and as an NTM machine owner, you have free access to testing and engineering for most NTM panels formed from Sheffield coil.

- A relationship with Sheffield Metals provides easy access to both machine and metals support.

What it means for you: A streamlined operation, quick solutions, and less time on the job.

10) One Family: New Tech Machinery and Sheffield Metals

- Sister brands: You benefit from coordinated support between the machine maker (NTM) and the coil supplier (SMI). No coil supplier will know more about NTM machines than SMI, so you’re always getting the support you need, relevant to your machine and profile.

- Focus on contractor success: Our mission is to support your operation so that you can focus on high-quality panels, not machine issues. Our highly qualified service team is just a phone call away. We have an in-house service facility at our main plant in Aurora, Colorado, and service techs who can travel to your location. We align our services with your goals and priorities around safety, quality, and efficiency.

What it means for you: An NTM/ SMI partnership that aligns with your business needs.

Practical Tips for NTM Owners Buying Coil From SMI

- Match coil width to profile: Confirm finished panel coverage, rib geometry, and hem consumption to select the correct coil width for your NTM profile.

- Confirm gauge and temper: Check your NTM manual for allowable ranges and verify with SMI when switching substrates or moving between snap-lock and mechanical seam profiles.

- Plan color lots: Order enough from the same batch for continuous elevations to avoid subtle shade shifts.

- Store properly: Keep coils dry, elevated, and covered. Avoid long-term storage in plastic wrap to prevent sweat/condensation.

- Test run: Before the full run, form a few panels to validate seam fit, rib tolerances, and clip engagement—adjust entry guides and tooling as needed.

What NTM offers:

- The industry’s best portable rollforming machines

- Machine training & support

What SMI offers:

- Free access to panel testing & engineering for NTM machine owners

- Metal coil tested for most NTM panel profiles

- Warranty support

- NTM machine support

- Architect Hub

- Homeowner Hub

FAQ: Benefits of Using NTM & SMI

Wrap-up: Make Your NTM Machine—and Your Business—Run Smarter

When you pair an NTM portable rollformer with Sheffield Metals coil, you’re not just feeding a machine but building a partnership. SMI’s coil is engineered to run through NTM portable rollformers, backed by quality coatings, panel testing and engineering, technical support, and warranty programs. Further, SMI representatives can use their knowledge of NTM machines to ensure that you have the right coil for your panel profile.

As a result, every standing seam job is a collaboration where you know you can rely on your NTM and SMI partners to support your rollforming operation.

If you’re an NTM owner, you also get something most suppliers can’t offer: Alignment between the machine maker and the metal provider. That means faster answers, fewer variables, and a single team that understands how coil, tooling, and profile specs and engineering come together.

Contact Sheffield Metals to speak with a knowledgeable representative for more information on coil.

Speak with an experienced account manager for information on New Tech Machinery portable metal roof panels, wall panels, or seamless gutter machines.