Are you looking to offer a flush wall / soffit panel profile to your customers or want to add more versatility to your metal roofing projects? Understanding the NTM flush wall / soffit profiles, their applications, and which machine can form them can help you decide if this option is right for you.

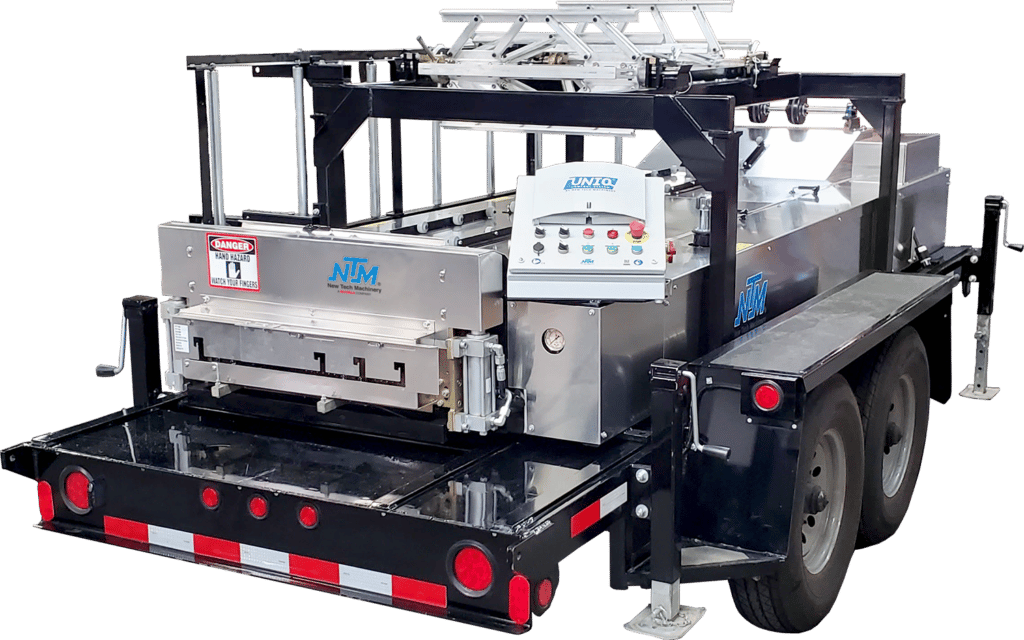

For years, New Tech Machinery has helped educate contractors and panel suppliers on the different roof panel machines available and what profiles they can produce to help make their companies more versatile and profitable. The fact that the SSQ II™ MultiPro Roof Panel Machine can form 14 roof panel profiles, as well as specialty 1” or 1.5” flush wall / soffit profiles, makes it an advanced and more unique machine than the SSH™ MultiPro or SSR™ MultiPro Jr. roof panel machines.

In this article, we’ll cover:

- The specifications of the FWQ profile, application, and materials used to form this profile

- Which NTM machine produces this type of profile

- Benefits and drawbacks of using the FWQ profile

- Unique aspects of the flush wall profile

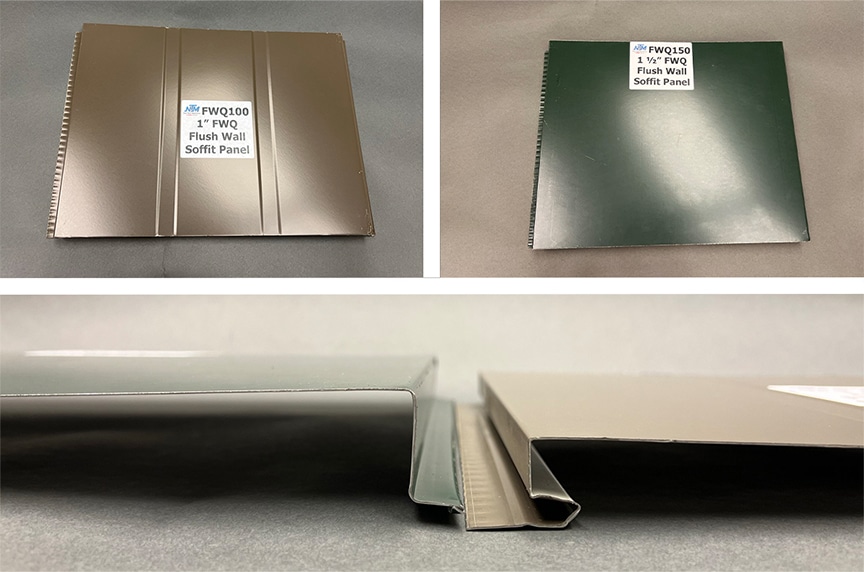

Specifications of the FWQ100 and FWQ150 Flush Wall / Soffit Panel Profiles

The flush wall profile takes on the appearance of a flat metal sheet as it sits “flush” against the wall. The soffit refers to the underside of a roof’s eave. This wall panel would protect that part of the roof system against harsh weather.

You can use this metal wall panel profile for residential and commercial applications, but it’s more common in commercial roofing. One of the benefits of this profile specifically is that it can also be used as an under-decking panel (a system of panels and gutters that are installed underneath a deck to keep it dry), not only as a flush wall and/or soffit profile.

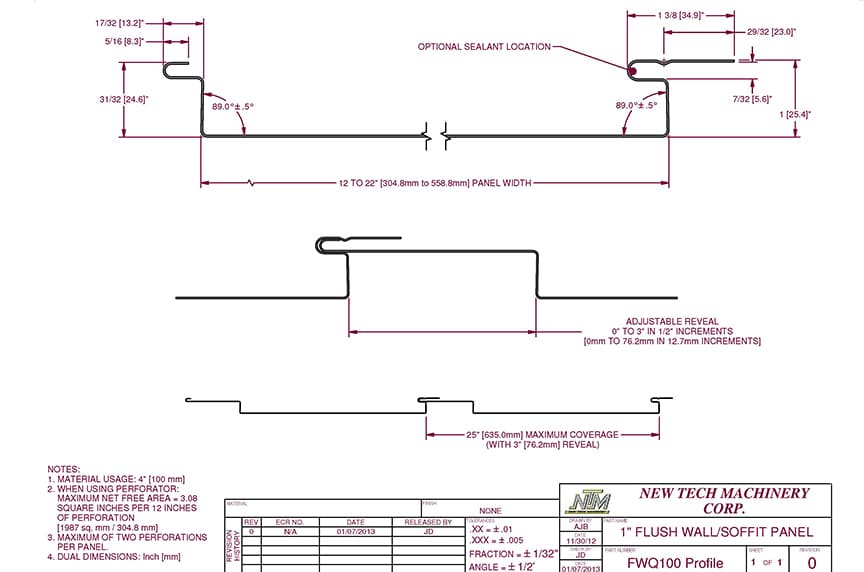

The flush wall / soffit / under-decking profile available with the SSQ II™ MultiPro Roof Panel Machine comes in two panel seam heights: 1” and 1 1/2”. The panel seam on the FWQ100 is 1” and the panel seam on the FWQ150 is 1 1/2”.

Both have the option to form an adjustable reveal (the reveal looks like a gap between panels) from 0” to 3” in 1/2” increments. The FWQ100 and FWQ150 wall panel profiles have a finished panel width of 12” to 22” and maximum coverage of 25” when utilizing the full 3” reveal.

When using your roof panel machine to form the FWQ100 or FWQ150 profile, it’s recommended to use 22 ga., 24 ga., or 26 ga. Grade 50 steel (painted, Galvalume, or coated galvanized). If you’re going to use aluminum, it’s best to use .024 to .040.

Another thing to consider is that oftentimes a specification will call for a 12” or 16” wide panel as a standard. This is not typically an issue for the FWQ100 as it only uses 4” of material in the seam, allowing you to easily secure a 16” coil for a 12” finished panel or a 20” coil for a 16” finished panel. However, the FWQ150 uses 5” of material to form the seam. Therefore, to achieve a 12” or 16” finished panel, you may have to budget for some additional drop coil or scrap coil.

These materials are recommended for the best quality panel and to reduce the risks of any oil canning. Using other materials thicknesses outside of recommended ranges could potentially damage the forming rollers or machine itself and would void your warranty.

What NTM Portable Roof Panel Machine Can Form Metal Flush Wall Panel Profiles?

As of 2022, the only machine that can make this metal wall panel is the SSQ II MultiPro. Why? Because of the specifically-designed length and roller set situation of the SSQ II, and the complexity of this specific profile, the flush wall / soffit profiles are better suited to be formed with a machine with more forming stations as opposed to a smaller machine like the SSR™ MultiPro Junior Roof Panel Machine.

The reasoning behind this is simple: the more forming stations and forming rollers a machine has, the more gradual the rollforming process is. Hence, there will likely be less stress on the material as it passes through the machine and will produce a higher quality profile. Having more forming stations inside the machine can also help reduce the possibility of oil canning.

Benefits of the FWQ100 or FWQ150 Flush Wall / Soffit Profile

The FWQ100 and FWQ150 panel profiles are versatile in that you can use them as a wall panel, soffit panel, and under-decking. The roller set also has an optional perforator / crimper that adds venting holes to the finished panel for use as a vented soffit panel. It also has a 0” to 3” adjustable reveal on the roller set assembly that you can engage as it suits your project requirements.

Before manufacturing the SSQ II machine, New Tech Machinery had a single designated machine to make flush wall panel profiles. However, adding this profile to the SSQ II machine increased the versatility, allowing customers to produce more profiles without having to purchase additional machinery.

Drawbacks to the FWQ100 or FWQ150 Flush Wall / Soffit Panel Profile

One of the downsides of this profile is that the narrowest soffit you can form is 12”, which may be too large for typical residential applications. One way to give the panel the illusion of a smaller soffit profile is to use 1-2 small V rib rollers to break up the profile if the project can accommodate a 12” wide soffit profile.

Testing on this panel is available if your project calls for it, but only through certain coil suppliers (for example Sheffield Metals International). Always check which flush wall configuration has been tested, as some testing may not cover installations with a reveal or in horizontal applications. To adhere to engineering specifications, you may also have to install the panel in a more labor-intensive way.

What’s Unique About the NTM Flush Wall / Soffit Profile?

The FWQ100 and FWQ150 are not your traditional siding profiles. What makes this metal wall profile unique from other flush wall / soffit panels? Here are some aspects of the FWQ profile that make it worth considering with your SSQ II machine:

- The FWQ100 and FWQ150 have an optional perforating assembly for you to add ventilation to the soffit panel. This assembly does not come with the perforator roller sets but they are available for an additional cost.

- When loading coil and feeding coil into the machine to form this specific profile, it needs to be turned so that the painted side is down.

- This profile has an adjustable reveal from 0” to 3” in half-inch increments. This reveal gives a board and batten type of appearance to the panel.

- The reveal on the flush wall profile can be adjusted quickly in the middle of a job offering designers a variety of custom looks with minimal associated costs.

- You can install the FWQ100 or FWQ150 wall panel profile horizontally or vertically.

- The first several tooling stations for this profile are connected in such a way that performing a changeover is slightly different than it is with other profiles. See your manual for instructions on installing the flush wall profile tooling.

- The FWQ100 and FWQ150 share many of the same roller stations. If you own one of these roller assemblies, you can purchase the other at a reduced price.

Final Thoughts

When considering what portable roof panel machine to add to your metal roofing business, having the versatility to offer roof and wall panel profiles is an advantage for your business and your customers, setting the SSQ II MultiPro out amongst all competitors.

Having the soffit, under-decking, and wall panels the same material and color as the metal roofing can help ensure a clean look for your project and save you time and money by making it all with the same machine.

If you’re considering adding the FWQ100 or FWQ150 flush wall / soffit profile to your lineup, remember:

- It has various uses: flush wall, soffit, or even under-decking.

- The profile has an adjustable 0” to 3” reveal, giving it a board and batten look.

- Only the SSQ II roof panel machine can make this type of profile.

- Use only the recommended materials and thicknesses, so you avoid potential oil canning or roller / machine damage.

We’re here to help answer any of your questions about the profiles available with a New Tech Machinery portable rollformer, how the SSQ II MultiPro can enhance your business, or how the flush wall profile works with the SSQ II machine. Just contact us to talk to one of our rollforming specialists today.