Metal Board and Batten Siding: A Contractor’s Golden Opportunity

Is fabricating metal board and batten metal siding worth the investment?

If you’re looking to diversify your metal roofing business, metal board-and-batten siding might be your answer. This classic barn-style siding is found everywhere from farmhouses to barndominums to urban homes, and contractors are capitalizing on the trend by adding it to their metal roofing and panel manufacturing operations.

Whether you’re a roofing contractor or panel manufacturer, fabricating metal board and batten gives you the opportunity to expand your business with a product that mimics traditional wood siding, minus the drawbacks of real wood.

In this article, we’ll explain exactly what we mean by board and batten (in case you’re not familiar with this traditional siding), cost, business opportunities, and the equipment you need to get started.

What Exactly Is Board and Batten?

Board and batten has been around since the 1800s – think classic barn siding with wide vertical boards and narrow strips (battens) covering the seams. It came about for a practical reason—the batten covers the space between the boards to keep out cold and wind. Over time, it became that classic farmhouse look that’s never gone out of style. In fact, with a surge in mixed-material homes, agricultural structures, and barndominiums, it’s more prominent than ever.

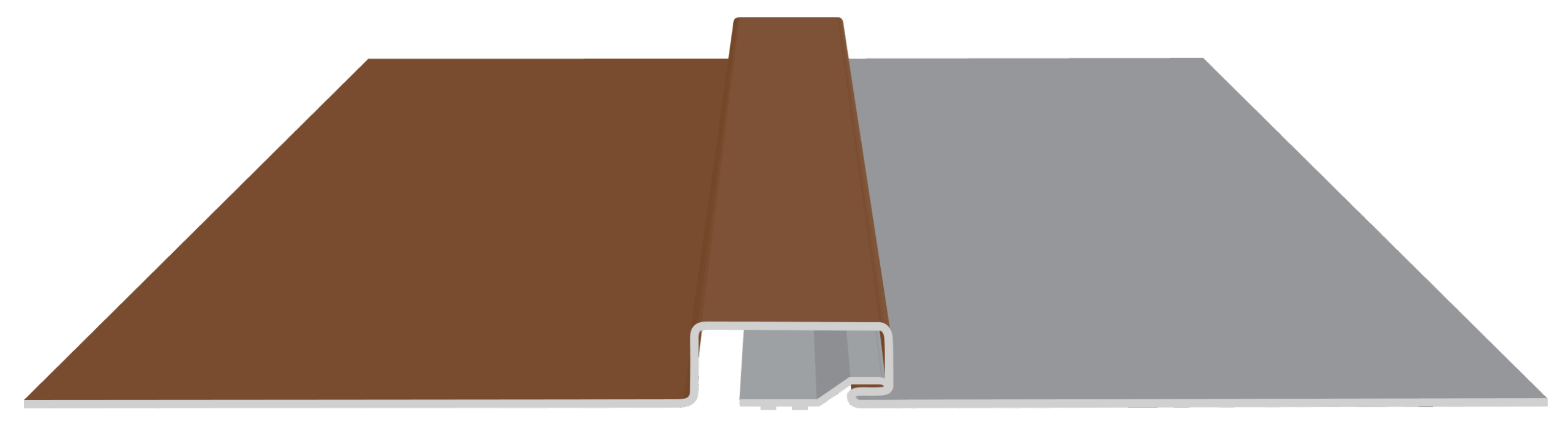

Modern metal board-and-batten uses steel or aluminum panels to replicate the traditional look. Each panel has an integrated batten rib that snaps over the edge of the next panel, hiding fasteners and creating that authentic board-and-batten appearance. The result? You get the classic aesthetic without dealing with rotting wood, warping, or insect infestation.

New Tech Machinery’s board and batten profile produces panels with a 2-inch-wide by ¾-inch-deep batten that covers the nail flange of the neighboring panel – just like traditional wood battens, but built to last decades longer. If you own an SSQ (dating back to 2014), you’re most of the way there. All you need is to add the profile.

Another benefit is the versatility of style, which we’ll get to in the next section.

Why Your Customers Will Love Metal Board & Batten

The B&B Style Factor

Metal board and batten isn’t just functional—it’s versatile. You can offer customers everything from rustic farmhouse vibes to sleek modern designs. With advanced coating technologies like Steel Dynamics’ Tru-Steel HD, you can get realistic woodgrain finishes that are convincing even from close up.

The creativity is in the customization. Since you’re rollforming from coil stock, you can make panels in whatever width and length the job requires. Want to mix narrow and wide panels for that authentic old-barn look? No problem. Need horizontal installation for contemporary flair? You got it.

Metal Siding Performance

Here’s what you can tell your customers about metal siding:

Durability: Steel and aluminum don’t rot, warp, or crack. They survive severe temperature swings that would damage wood siding. And since the battens cover all the fasteners, you don’t have to worry about exposed screws rusting or backing out.

Longevity: This is a big selling point: 50+ years with minimal maintenance. Compare that to wood siding that might need major work every 15-20 years, and you can see why customers are making the switch.

No repainting every few years, no replacing rotted boards, no worrying about termites or woodpeckers. The factory paint finishes are engineered to last, so once it’s up, it’s basically set-and-forget.

Fire Resistance: Non-combustible siding can save your customers up to 20% on their homeowners insurance. In wildfire-prone areas, this isn’t just a nice bonus – it’s becoming a necessity. It’s also worth LEED credits for its sustainability. Plus, metal is 100% recyclable forever.

The Numbers Game: Metal B&B Cost vs. Value

To be fair, metal B&B isn’t the cheapest option upfront. Your customers will be sure to point this out. And you’ll know from dealing with metal roofing that not everyone is your customer—it’s a niche market, and some folks will be priced out. That said, we’re seeing metal board and batten on apartment complexes, commercial structures, residences, and farm buildings. Yes, it’s really a thing.

When you factor in the life-cycle costs, it’s no contest; metal wins hands down. No repainting every few years, no replacing damaged boards, no ongoing maintenance headaches. Plus, there are often insurance discounts and potential energy efficiency rebates that help offset the initial investment. And it will last decades. Your customers’ kids will have grown kids of their own before it needs replacing.

Getting Set Up With Metal Board & Batten: NTM Equipment You Need

As mentioned, if you’re already running a portable rollformer, you might be closer to offering board and batten than you think. New Tech Machinery’s SSQ II MultiPro can run board and batten profiles, and our engineers even retrofitted the tooling for older SSQ machines from 2014.

The profile became the 16th available option on the SSQ II. NTM developed it specifically because contractors kept asking for a B&B option, and the orders came flooding in. It remains one of our most popular profiles.

You’ll typically run 24 or 26-gauge steel or 0.027″ to 0.032″ aluminum coil. The SSQ II can handle coil widths from 15″ to 30″, giving you finished coverage from about 10″ to 25″ for the B&B profile. The automatic hydraulic shear lets you cut panels to exact lengths on-site – a huge advantage when you’re dealing with tall walls.

NTM Board-and-Batten Projects

This isn’t just theory – contractors are already making money with metal board and batten. Take The Legacy Project in Greeley, Colorado – a Western stock show building that needed about 18,450 square feet of board and batten siding. The city chose metal with a wood-grain finish over stucco, even though it cost about $20,000 more, because they wanted the authentic look with long-term durability.

This was one of the first projects to combine board-and-batten siding with woodgrain metal, and it was even featured in Rural Builder Magazine.

Flatiron Steel, the manufacturer that ran those Legacy panels with an SSQ, reports filling B&B orders two to three times a week consistently. That’s steady demand, and it’s growing.

The applications are everywhere:

- Modern farmhouse homes (huge trend right now)

- Barndominiums and agricultural buildings

- Commercial projects wanting that warm, welcoming look

- Even interior accent walls for restaurants and retail spaces

Why Board and Batten Makes Sense for Your Business

The roofing market is competitive. Adding metal siding – especially a high-demand profile like board and batten – gives you another way to serve your existing customers and attract new ones. If you’re a panel manufacturer, talk to some local contractors. They may already be ordering B&B panels from another supplier or looking for a manufacturer who can meet the demand.

You’re already known for servicing the most essential home protector (the roof), so it’s a natural extension to offer metal walls, too. Plus, the installation skills translate well—if you can handle standing seam, you can handle the easier board-and-batten siding.

The market is telling you this is where it’s heading. Homeowners want the farmhouse look but don’t want the maintenance nightmare of wood. Builders are specifying metal siding more often because they’re tired of callback issues with other materials.

Bottom Line on Metal Board and Batten Siding

Metal board and batten siding represents a solid opportunity to grow your business with a product that actually delivers durability and style. It gives customers the look they want without the hazards of wood, and it gives you a chance to expand beyond standing seam.

The equipment is available, the market demand is proven, and the profit margins can be good if you position it right. Whether you’re looking to diversify your services or just give your customers more options, metal board and batten is worth serious consideration.

For more information about our board and batten profile, or for any NTM machines and accessories, contact us to speak to an expert account manager.

Ready to learn more about adding metal board and batten to your services? The technology is proven, the market is there, and the opportunity is growing. The question isn’t whether this trend will continue – it’s whether you’ll be part of it. Call us today.