The drive rollers in a portable rollforming machine are an integral part in creating quality panels and gutters. Knowing how to clean these drive system components is essential for producing well-formed metal roof panels and gutters and keeping your machine in top working condition.

Since 1991, New Tech Machinery (NTM) has manufactured portable rollforming machines and equipment, and our Service Department talks with clients about the importance of proper maintenance and inspection of your machine. Even something as simple as understanding how and why to clean your drive rollers can make a world of difference in the panels and gutters you make.

In this article, we’ll go through:

- What supplies you’ll need to clean your drive rollers

- Steps on how to clean your machine’s drive rollers

- How to know when to clean your drive rollers

- Potential problems of improper care or maintenance of drive rollers

How to Clean Your Portable Rollforming Machine’s Drive Rollers

Proper and routine maintenance of your portable rollforming machine is essential. Not only does it improve the quality of the panels or gutters formed through your roof panel machine or seamless gutter machine, but it also is one of the easiest ways to keep your machine in top condition for a long time.

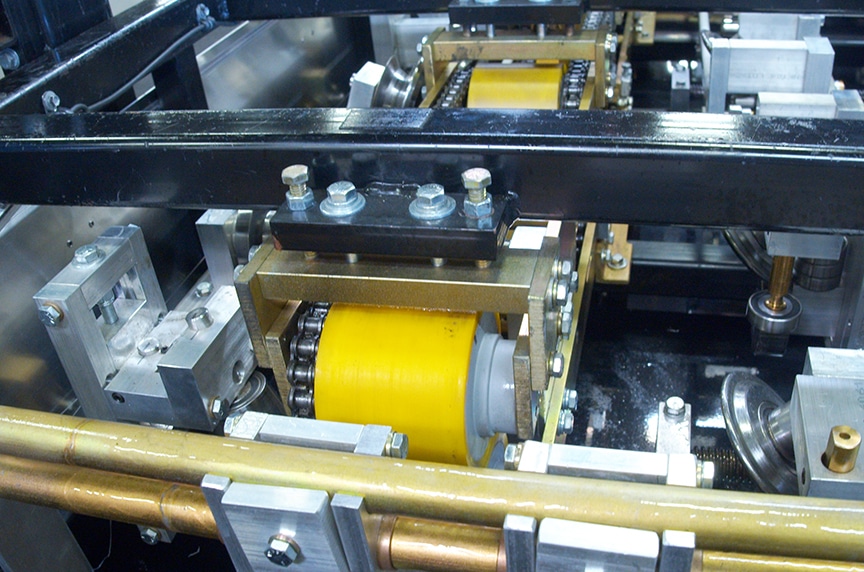

For the purposes of this article, we’re only going to explain how to clean the drive rollers in any New Tech Machinery portable rollformer. In your portable rollformer, the drive system that pulls the material through the machine comprises a series of top and bottom polyurethane drive rollers. The number of drive rollers inside your machine varies depending on the type and length of your machine.

For example, on the SSQ II™ MultiPro Roof Panel Machine, there are eight top and eight bottom drive rollers. Divided into groups of two per drive assembly, this makes four top drive roll assemblies and four bottom drive roll assemblies.

Supplies Needed to Clean Drive Rollers

What do you need to clean the drive rollers in your NTM machine? You won’t need many tools or supplies to clean your drive rollers, but we recommend using the following:

- Clean cloth rags

- Simple Green® degreaser (or any other mild general-purpose cleaner)

- Green Scotch-Brite™ pads

The drive rollers are made of polyurethane, so be sure NEVER to use harsh chemicals or solvents when cleaning them.

Procedure for Cleaning an NTM Portable Rollforming Machine Drive Rollers

Before you begin cleaning the drive rollers, you’ll want to make sure you take the following safety precautions and best practices when operating your portable rollforming machine:

- Remove any material that may be inside your machine already.

- Remove the top covers from the front to the back of the machine.

- Inspect the inside of your machine to make sure there’s no debris inside it and that all internal components are in functioning order.

- Turn off your machine by unplugging the power source on electric-motored machines, unplugging the yellow power cable at the gas Quick-Change™ Power Pack on gas-powered machines. Or, if you have a new SSQ II machine with the UNIQ® Automatic Control System, turn the power off and utilize the lockout/tagout on the disconnect switch.

Now you can begin cleaning your drive rollers. You must use caution around the machine’s moving parts during this cleaning process.

- Spray two sets of the rollers with the Simple Green cleaner, but be careful not to spray the drive chains and bearings. To help protect these components, you can use cardboard as a shield around the rollers to control overspray.

- Reconnect the electrical source for electric-motor machines or reconnect the yellow power cable for gas-powered machines.

- Turn the machine on and jog forward until the degreaser starts to dry. Stop your machine and jog in reverse about 2-3 inches to move the degreaser to an accessible location.

- Turn off your machine again. Unplug the power source on electrically-powered machines or unplug the yellow power cable at the gas Quick-Change™ Power Pack for machines that utilize gas. If you have a new SSQ II machine with the UNIQ® Automatic Control System, turn the power off and utilize the lockout/tagout on the disconnect switch.

- Wipe down as much degreaser as possible with the cloth rag or Scotch-Brite pad.

- Connect either the electric source or yellow power cable again, depending on if your machine is electric or gas-powered.

- Turn your machine back on and jog another 2-3 inches to move the degreaser to an accessible location.

- Turn off your machine again and follow the same instructions in number 8.

- Wipe down any remaining degreaser on the rollers

- Repeat steps 4-13 for the remaining drive rollers or for additional cleaning on extremely dirty drive rollers.

- When finished, reconnect the electrical source for electric motor machines or reconnect the yellow power cable on gas-powered machines. Test your machine function to ensure the degreaser is entirely wiped off and that your machine is running material properly.

- Replace all the covers on your machine before you begin operating your portable rollforming machine.

To read these instructions on your phone, tablet, or another device, download the free “Drive Roller Cleaning Procedure” by clicking on the link below.

Considerations When Cleaning Drive Rollers on Your NTM Portable Rollforming Machine

As a portable rollforming machine owner or operator, taking care of your machine is essential. Not only can it save you on replacement parts or machine service in the future, but it can help ensure that you’re producing quality panels and gutters free of deformities or scratches.

Knowing When to Clean the Drive Rollers in an NTM Machine

How often should you clean your New Tech Machinery portable rollforming machine’s drive rollers? Well, that answer varies depending on how often you use your machine and what kinds of environments you’re using your machine in.

A safe interval we recommend is inspecting and cleaning the drive rollers every three months unless your machine shows signs of dirty drive rollers. If you see that there’s dirt on your drive rollers, clean them more often.

You’ll know when the drive rollers on a panel machine needs cleaning when they leave a stripe the width of the drive roller on any finished panels that doesn’t come off easily. In gutter machines, the drive rollers will have a black smudge on the gutter due to the drive rollers slipping on the material.

Proper and regular maintenance of your portable rollforming machine can’t be stressed enough. Not only does it save you on possible expensive service repairs or replacement parts, but it also helps ensure you won’t be wasting time or money on a project while your machine is down and you can’t run panels or gutters.

If you have any questions about any maintenance action on your NTM portable rollforming machine, check out your machine manual on our website. You can also find instructions on machine maintenance, operation, and troubleshooting for all NTM machines.

Potential Problems from Improper Maintenance of Drive Rollers or Care of Portable Rollforming Machine

What could happen if you don’t make cleaning your drive rollers a part of your machine operation and maintenance routine? There are a variety of issues you could run into, including:

- Improper storage of your machine (like leaving any material inside your machine, keeping your machine outside for a long time without a cover, or leaving the covers off during operation) may result in the rollers collecting dust or debris, ruining the polyurethane, or making the rollers dirty.

- Rippling or an indentation ripple on the bottom of a finished gutter may happen when foreign material (like tape or caulking) that’s stuck to the top or bottom roller or a gouged roller from something accidentally run through the machine (like a spike, ferrule, etc.). Proper cleaning and inspection of your drive system can help prevent these common gutter problems.

- Exposure to ultraviolet light can harm the polyurethane on the drive rollers and cause deterioration. This type of damage is not covered under warranty, so it’s best to keep all covers on your machine during operation and storage.

- Using harsh chemicals or solvents to clean your drive rollers can eat away at the polyurethane over time. That’s why we advise using soap and water or the Simple Green cleaner instead.

- Using poor quality tape to tape down your coil can cause some of the adhesive to rub off onto the drive rollers as the material is going through the machine. Before you feed material through your machine, discard the first and last lap of coil to ensure no tape reside will end up on your drive rollers or other internal components of your machine.

- Panel markings are marks (like long streaks or imperfect spots shown below) on the top or bottom of panels that may happen during the rollforming process. Panel markings occur when dirt and debris are trapped in the drive and forming rollers, causing scratches in the material as it’s formed in the roof panel machine. Keeping your rollers clean and inspected can help you avoid this roof panel machine problem.

Final Thoughts

Knowing why it’s important to clean your machine’s drive rollers and how to properly do it doesn’t have to take a lot of time. The more you make it a part of your routine maintenance procedure, the easier it will become.

Cleaning your drive rollers can help in various ways:

- You can potentially save downtime on projects or requiring more material if your drive rollers are damaged or have debris caught in them.

- It helps you save money on potential repairs or service to the drive system.

- It increases the overall life of your machine and its drive system.

- You can reduce or eliminate marks on panels or gutters as they are produced.

- You’re able to keep your customers happy with top-quality panels and gutters.

At New Tech Machinery, we know the importance of your machine running smoothly and making excellent metal roofing or gutter products. We strive to keep our clients educated, informed, and up to date on proper maintenance and machine operation best practices.

If you’re looking for a downloadable or printable set of instructions on how to clean your portable rollforming machine’s drive rollers, check out our “Drive Roller Cleaning Procedure” PDF. If you have any other maintenance, service, training, or troubleshooting questions (even over the phone), reach out to us, and we’ll put you in touch with one of our Service Department managers.