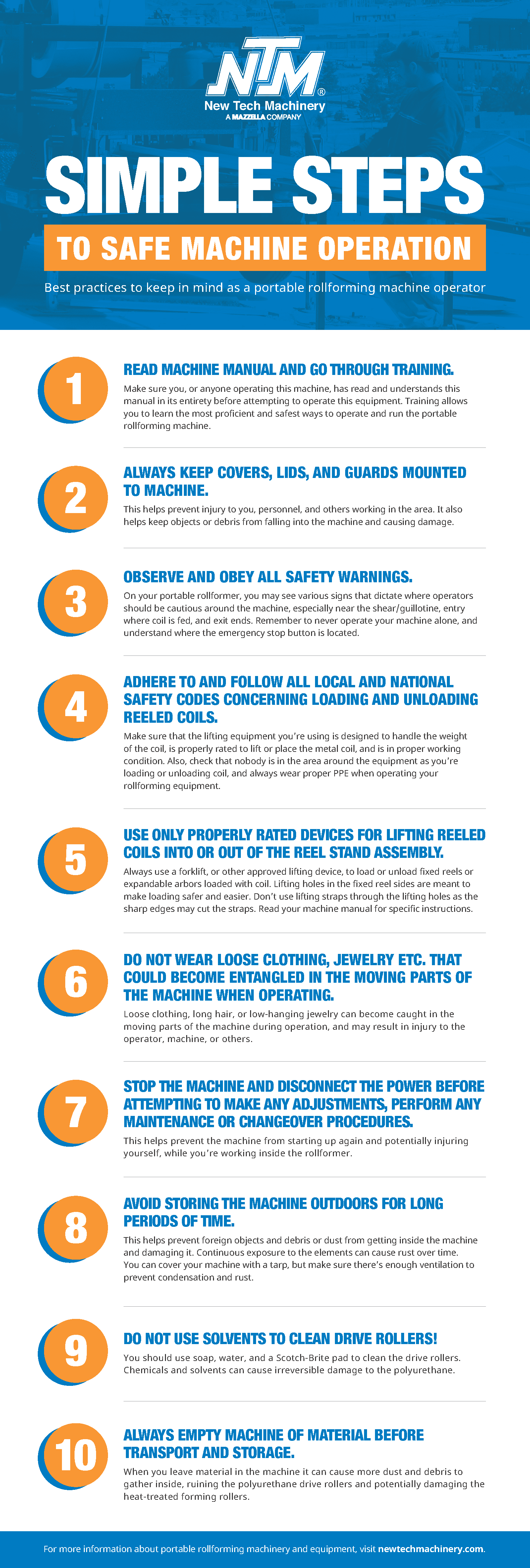

Operating portable rollforming machines, like any heavy equipment, can come with risks, especially if you don’t understand the best safety practices to take when using these machines. However, you can be a safe portable rollforming machine operator by following these simple steps.

Keep reading for more information about the best safety practices when using a portable rollforming machine that can help keep yourself, others, and your machine from risks or harm. You can also download our “Simple Steps to Safe Machine Operation” infographic to post in your facility for quick reference or to share with new employees.

10 Simple Steps for Safe Portable Rollforming Machine Operation

>> Click here to download a high-resolution version of the infographic! <<

1. Read the machine manual and go through training before attempting to use your machine

First and foremost, you must understand how the machine works inside and out. We recommend reading through the machine manual and signing up for training from a skilled service tech.

The machine manual is one of the most valuable tools you can have on hand when using your portable roof panel or gutter machine. It has all the details you need to know for performing profile changeovers, troubleshooting common problems, and maintaining your portable rollforming machine. This video walkthrough discusses where to find your machine manual, how to use it, and which sections are essential for safe and efficient machine operation.

As much information as your machine manual provides, a training session allows new machine operators a hands-on approach to learning the safest ways to run a portable rollformer. Having your employees go through machine training also helps to

- Avoid injuries to machine operators, or other employees

- Understand how to run different types and grades of materials

- Maintain high productivity and quality of end product

2. Always keep covers, lids, and guards mounted to the machine during operation

The Occupational Safety and Health Administration (OSHA) outlines guarding requirements for all machines in regulation 1910.212. OSHA instructs: “One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, ingoing nip points, rotating parts, flying chips and sparks.”

The shear is extremely dangerous and can cause serious bodily injury or death. For this reason, the machine is provided with a guard to prevent the operator from reaching into the shear. The guards must remain in place at all times when the machine is in operation.

Keeping the covers and lids on your machine also helps protect the portable rollformer by making sure harmful and damaging items don’t get inside. Debris, dust and foreign objects can damage machine components or material running through the machine, and potentially hurt other people.

3. Observe and obey all safety warnings

All machine operators and employees should know the locations of safety signs, what they mean, and follow all safety protocols associated with these warning signs and machine operation.

On a portable rollforming machine, various signs dictate where operators should proceed with caution around the machine, especially near the shear/guillotine, the entry end where coil feeds through, and the exit end where the panel or gutter comes out.

Safety warnings and signs include:

- ”Keep guards in place” located next to the shear or guillotine

- “Keep hands clear” or “Hand hazard, watch your fingers” found by the shear or guillotine at the exit end of the machine

- “Don’t operate with covers removed” signs on the top of the machine covers

- “Keep hands away from rollers” found at the entry end of the machine

Remember never to operate your machine alone, and make sure you know where the emergency stop button is.

On some of the New Tech Machinery roof panel machines, the emergency stop looks like a raised red ‘mushroom,’ located on the machine’s control panel. When the machine is running, pushing the emergency stop button will cease all functions and completely shut down the machine, including the engine. If the shear is in the down cycle, the shear blade will freeze in its current position. This button also shuts down the machine when not in use.

4. Adhere to and follow all local and national safety codes concerning loading and unloading reeled coils

When loading and unloading reeled coil on fixed reels, cradles, or expandable arbors, use a properly rated and approved lifting device or forklift. Always keep your lifting device in good order, according to manufacturer recommendations. Use only experienced operators to operate your lifting equipment, as well as follow all local codes regarding use of this kind of equipment. Also, be sure to remove the straps from the coil before loading material onto the machine.

If loading or unloading metal coil on a turnstile reel stand, don’t attempt to load or unload the coil if the reel stand is unsecured. The locking device on the reel stand must be securely in place before loading and unloading coil. The maximum load capacity on reel stands is 1,000 pounds for each reel.

When using reel stands, reels, and expandable arbors the maximum load capacity for each reel is 3,000 pounds. Total capacity for reel stand is 6,000 pounds. For reference, this helpful video shows the correct way to load coil onto a portable gutter machine.

5. Use only properly rated devices for lifting reeled coils into or out of the reel stand assembly

When selecting a proper lifting device, you want to make sure that it can handle the coil’s weight, is in proper working condition, and is properly rated to lift or place the reeled metal coil. Ensure nobody is around the rollforming machine and equipment while lifting the coil into or out of the reel stand/rack to avoid any accidents or injuries.

Different devices can lift metal coil, including:

- C-hook lifter or two-arm coil grabs – Best for lifting coil stored with the eye in a horizontal position.

- Vertical eye coil lifters – Use this device to lift the coil when it’s stacked vertically and after the coil is already slit.

You can also read your machine manual for specific instructions on lifting, loading, and unloading reeled coils from expandable arbors and reel racks depending on which portable rollformer you use.

6. Don’t wear loose clothing, jewelry, etc. that could become entangled in the machine’s moving parts

In rollforming machines, the metal coil goes through a series of rollers that progressively bend and shape the material to the desired profile. Wearing loose clothing or low-hanging jewelry can become caught in these moving parts during operation or when close to the portable rollformer and could injure the operator, those around the machine, or damage the machine itself.

It’s also important to remember to wear the proper personal protective equipment when operating or maintaining your rollforming equipment, including safety goggles, hard hats, and close-toed shoes/boots.

7. Stop the machine and disconnect the power before attempting to make any adjustments or perform any maintenance or changeover procedures

As obvious as it may seem, machine operators must remember to stop the portable rollformer and disconnect the power before making any adjustments, performing any machine maintenance actions, or changing over profiles.

Not only does shutting off power prevent the machine from starting up again and potentially injuring yourself or others, but it also keeps your machine from crashing if tools get stuck between rollers or inside the machine.

8. Avoid storing the machine outdoors for long periods of time

Yes, portable rollforming machinery and equipment are designed to be used outdoors. However, storing them outside for a long time can cause problems. Continuous exposure to weather, like rain or snow, can cause rust to form over time.

It also prevents panel markings from forming. Panel or gutter markings can be a common problem with portable rollforming machines and happen when dirt and debris become trapped in the drive rollers and forming rollers and scratch the metal coil as it goes through the machine.

Therefore, keeping your machine inside helps minimize these types of problems. Additionally, if you’re going to cover your machine with a tarp, make sure there’s enough ventilation to prevent condensation and rust.

9. Don’t use solvents to clean drive rollers

Maintenance of your portable rollforming machine is key to a long-lasting machine in top condition. However, some cleaning agents can ruin machine parts.

Some portable rollforming machines have polyurethane drive rollers. Polyurethane is a kind of plastic material that can take on different forms such as rigid or flexible foam, coating or adhesive, or a binder. It is used in various applications like building and construction, packaging, or apparel.

Polyurethane strengthens the rollers, adds to their longevity, and is more resistant to environmental factors. Chemicals and solvents can damage the polyurethane, so take care and only use soap, water, or a citrus-based degreaser, and a Scotch-Brite pad to clean your drive rollers.

Your machine manual has a list of recommended lubricants and fluids to use when maintaining your portable rollforming machine.

10. Always empty the machine of any material before transport and storage

One of the significant advantages of using a portable rollforming machine is that it can be taken right to a job site. However, you want to remember to empty the machine of any metal material that may be inside before you transport it, and before you store it after use.

When you leave material inside the machine, more dust and debris can gather inside and damage the polyurethane on the drive rollers and the heat-treated forming rollers.

Final Thoughts

At New Tech Machinery, we manufacture and sell all kinds of portable rollforming machinery, including roof panel and seamless gutter machines. We also offer training, service, and post-sales support on all of our portable rollforming equipment, so you understand how to safely operate and maintain your machine.

If you have any questions about safely using portable rollforming machines or taking care of your rollforming equipment, contact one of our rollforming specialists today!