The Best Portable Rollforming Machine Manufacturers in 2025

Portable metal roof and wall panel rollforming machines have revolutionized the metal roofing industry in recent years, as contractors no longer have to rely on third-party manufacturers and distributors. Now, they can control their operations by fabricating panels on-site, which offers several advantages.

Not only have portable rollformers become the optimal tool for metal roofing, but metal siding, soffits, and underdecking can also be produced at the jobsite with a machine like NTM’s SSQ II MultiPro, the most versatile portable rollformer in the industry. As a result, contractors see less waste, higher production, and increased profits.

New Tech Machinery’s (NTM) SSR, SSH, and SSQ II MultiPro models are among the best known in the industry, but they’re not the only game in town. This article provides an alphabetically ordered review of the top manufacturers of portable rollformers in 2025 that produce machines similar to NTM’s. You’ll learn about each company’s offerings, notable features, and what makes them stand out for metal roofing professionals.

Bradbury Group

The Bradbury Group is a global leader in in-plant rollforming and coil processing equipment, specializing in stationary rollformers, precision roller levelers, cut-to-length machines, building trim equipment, and more. They also offer a portable standing seam rollformer for on-site use.

Bradbury’s portable roof panel machine is engineered to deliver in-plant production quality at the job site. A hallmark of Bradbury’s system is its integrated technology: it includes a Beck Cobalt® control for precise batch programming, an automated multi-batch length controller, and even an integrated mastic application system for applying sealant during panel forming.

This machine claims a production speed of up to 100 feet per minute – faster than most competitors. It features a rafted rollformer design, meaning multiple profile tooling sets are mounted on interchangeable rafts for quick changeovers between panel profiles.

Despite its impressive capabilities, Bradbury’s portable system is also known for being expensive. Bradbury portable rollformers are manufactured in Australia, so the additional shipping cost would only add to the steep price tag. Also, parts may not be as readily available in the U.S.

Bradbury’s reputation for quality and innovation is well established. Their portable rollformer stands out for its automation and speed – allowing contractors to form panels with factory-line productivity on site. If their advanced features are a priority and budget isn’t a concern, Bradbury is worth considering in the portable rollformer market.

Englert Inc.

Englert Inc. has been in the metal roofing business for over 50 years and offers a wide range of portable rollforming machines. Englert’s machines – known under the MetalMan label – are popular for contractors who want an all-in-one solution from a single provider (Englert supplies the metal coil, the machine, training, engineering, and support). Except for their Multi-Panel Machine, their portable rollformers each produce one profile with a single coil and finished panel width.

Their flagship portable system is the MetalMan Multi-Panel Roofing Machine, which can produce up to nine different standing seam profiles by changing out tooling cartridges. This multi-profile machine is often compared to NTM’s SSQ II. It offers a maximum forming speed of about 90 feet per minute, slightly higher than the SSQ II’s 75 ft/min.

However, the Englert machine runs with a 13 HP gas engine. In contrast, the SSQ II uses a 16 HP engine, meaning Englert achieves speed with a smaller motor (in practice, running at top speed may increase the risk of material jams). The machine can form steel from 30 gauge up to 22 gauge and aluminum from .019″ to .040″ thick.

Englert sets itself apart by offering a whole-system approach. When you buy an Englert machine, you also access their training and certification programs, machine warranty, and engineering services to help ensure your panels meet specifications.

This is a draw for contractors who value a one-stop solution. In addition to the multi-panel machine, Englert produces simpler fixed-profile MetalMan machines for those who consistently need only one panel type. These smaller electric-powered units produce a single profile (e.g., a 1” nail-strip snap-lock or 1½” mechanical seam) at about 40 ft/min and are great for contractors focused on one style of panel.

Overall, Englert’s portable rollformers might not have as many profile options as NTM’s largest model, but they cover all the popular seam types and come bundled with the kind of customer support that many contractors appreciate.

One thing to remember is that although Englert keeps most machine parts in stock in the U.S., if unavailable, parts can take some time to arrive as they must be shipped from Poland. Also, their parts are metric, making them difficult to substitute.

New Tech Machinery (NTM)

New Tech Machinery is often considered the pioneer of modern portable rollforming machines. Founded over 30 years ago, NTM focuses exclusively on portable metal roof and wall panels and gutter machines and introduced innovations like separate drive and forming rollers, which many competitors have since adopted. Ron Schell, who innovated many of NTM’s rollformer technologies, holds multiple patents and was inducted into the 2025 Metal Construction Hall of Fame.

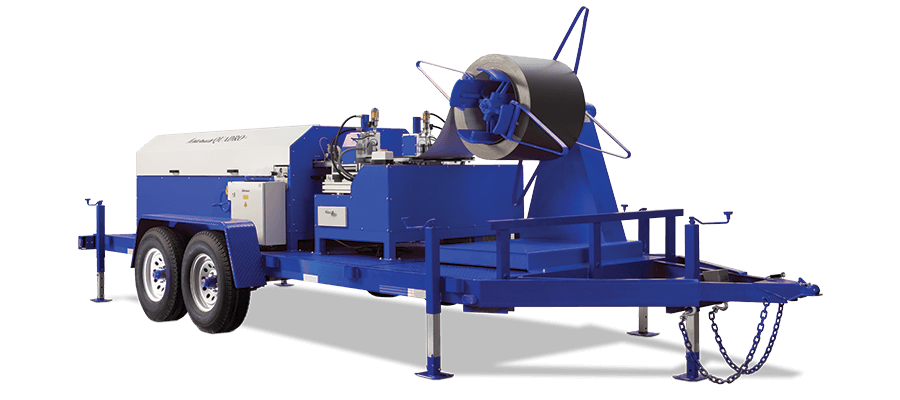

NTM’s line of portable roof panel rollformers includes the SSR MultiPro Jr. (entry-level), SSH MultiPro (mid-level), and the SSQ II MultiPro (their flagship). The SSQ II in particular is a versatile workhorse – it can run up to 16 different profiles, the most of any portable machine on the market, ranging from 1” and 1½” mechanical lock seams to multiple snap-lock profiles, flush wall/soffit panels, a proprietary dual-function 2” profile that can be snap-locked or mechanically seamed, and a board & batten profile that took the metal siding industry by storm.

Tooling changeovers on the SSQ II are designed to be relatively quick – one person can swap profiles in about 45 minutes. This flexibility allows contractors to take on a variety of panel styles without needing multiple machines.

NTM machines are known for their robust build and advanced but practical features, as they base their innovations on customer feedback. All NTM panel machines use polyurethane drive rollers, which provide excellent grip and can handle various material types and gauges with minimal adjustments.

The SSR and SSH models use a traditional chain-and-sprocket drive with eight drive rollers, while the larger SSQ II uses a heavy-duty gear drive with sixteen drive rollers for greater power. As a result, the SSQ II can run thicker materials (up to 22 ga steel) compared to 24 ga max on the smaller machines.

NTM also offers Quick-Change™ powerpacks – you can choose a gas engine or an electric motor and swap between them, giving flexibility to run in the field or in a shop.

Another area where NTM shines is in automation and safety: the SSQ II can be outfitted with the UNIQ® Automatic Controller for automated batching and length cutting, and it features safety systems like a shear guard and interlocking covers with LED status. The SSQ II MultiPro also offers optional notching and slitting features, which can elevate your panel fabrication to a whole new level.

Customer support is a big part of NTM’s reputation. They publicly list machine prices on their website for transparency and they provide free in-house training to new machine owners. NTM has a robust service department fully staffed with techs to problem-solve over the phone, at their facility, or at the customer’s location. NTM’s online Learning Center offers instructional how-to videos and articles for machine adjustments, maintenance, and more.

NTM’s focus on portable rollformers has made them a go-to manufacturer for contractors worldwide who want reliable, field-proven machines. In summary, New Tech Machinery stands out for its wide profile capability, innovative features, and industry-leading experience in the portable rollformer arena. If you need one machine to do as much as possible, the SSQ II (and NTM’s lineup in general) is hard to beat.

Roll Former Corp

Roll Former Corporation, now part of Tennsmith, has been a provider of portable rollforming equipment since 1978. They specialize in a variety of machines, including perforators, trim machines, and metal folders. Their lineup of portable roof panel machines offers solutions closely comparable to New Tech Machinery’s SSQ II, SSH, and SSR machines, ideal for metal roofing contractors who want on-site fabrication.

The VS-150 Standing Seam Panformer is Roll Former’s primary multi-profile machine. It produces seven profiles, including standard 1” and 1½” mechanical lock seams, snap-lock profiles, Bermuda panels, and board-and-batten style panels. It operates via an electric-hydraulic drive system with a hydraulic shear, capable of forming 26–22 gauge steel, .032” aluminum, and copper. The VS-150 produces panels at approximately 40 feet per minute, with quick tooling changes, dual polyurethane drive rollers, and an optional digital length controller for automated cutting.

Roll Former’s SLP-175 Snap Lock Panel Machine is tailored for 1¾” snap-lock panels, widely used in commercial metal roofing. Equipped with an adjustable width, it handles up to 22 gauge steel and .032” aluminum at speeds of about 40–50 feet per minute. Key features include an automatic Siemens digital controller, heavy-duty construction, and optional stiffening ribs or hot-melt sealant application during forming.

Roll Former Corp machines benefit from Tennsmith’s U.S. distribution, extensive training, and customer support network. With comprehensive after-sale services, readily available parts, and remote technical assistance, Roll Former Corp’s portable machines provide contractors with dependable performance.

Schlebach Maschinen GmbH

Germany’s Schlebach Maschinen GmbH has earned an outstanding reputation for precision in the metal forming industry over the last 40+ years. Schlebach is best known for its Quadro line of portable rollforming machines, which debuted in the late 1990s and introduced a unique approach to multi-profile rollforming.

Unlike most portable machines that require swapping out rollers on a single drive bed, the Schlebach Quadro uses exchangeable cassette modules: each cassette contains the roller dies for a particular profile and can be swapped in as a unit. This design makes profile changeovers extremely fast – you can switch from a mechanical seam profile to a snap-lock profile by rotating the cartridge rather than needing to changeover each roller station. The caveat is that the cassettes are heavy enough to require a forklift or hoist for changeovers.

The Quadro machines can produce a wide variety of panel profiles. For example, a Schlebach Quadro system can be equipped to run 1”, 1.25”, and 1.5” mechanical lock panels, several snap-lock profiles, nail strip (fastener flange) panels, high seam (2” mechanically seamed) panels, as well as flush wall/soffit panels, and board-and-batten siding. In total, the Quadro PLUS package offers around 10 optional profiles in one machine with the appropriate cassettes. This range comes closest to NTM’s SSQ II in versatility.

Schlebach’s Quadro builds on the cassette concept and integrates a computer-integrated notching and angle-cutting system (CINCO) for automated panel fabrication. It features a PLC controller, allowing users to input roof dimensions and have the machine automatically notch and cut panels to length and angle.

In terms of operation, Schlebach machines tend to use all-electric power (single-phase or three-phase supply) with hydraulic systems for punching/notching as needed. Their production speed is around the mid-range for portable machines – approximately 40–50 ft/min for most profiles, which is ample for most on-site residential work.

What makes Schlebach stand out is the unique design. The Quadro’s dual-drive system (with drive shafts on both sides of the machine) claims to minimize pressure and reduce oil-canning in the panels.

Schlebach doesn’t sell directly in the U.S. but distributes through MetalForming, Inc. in the U.S. market. They and their partners offer training (often for a fee) and support for the equipment. Schlebach offers a user-friendly yet highly advanced portable rollformer that appeals to those who prioritize quick profile switching and precision. For contractors who want top-tier German engineering and are willing to invest in the cassette tooling system, Schlebach’s Quadro series is a solid choice.

Zimmerman Metals

Zimmerman Metals is a U.S. manufacturer (based in Colorado) that brings heavy-duty craftsmanship to portable rollformers. With a long history in metal fabrication (dating back to 1936), in 1978 Zimmerman began producing portable roofing machines to meet the needs of contractors from residential through structural applications. Their machines are all made in the USA.

One distinguishing feature of Zimmerman’s design is a patented material handling system that keeps the material centered and uses a free-spinning forming rollers. This setup minimizes the potential for oil-canning (waviness) in the finished panels by reducing undue stress during forming. Essentially, the panel floats slightly as it’s being formed, which helps produce very flat, smooth panels even in wide widths. It works similarly to the separate drive roller/ forming roller systems.

Zimmerman offers several models of portable rollformers tailored to different segments: a Z-Panel Machine for residential profiles, a Commercial Machine, a Structural Machine (for heavier gauges and structural profiles), and even an Arch Machine building system for large commercial and agricultural units.

Focusing on the residential Z-Panel Machine – it’s a multi-profile rollformer that can produce five common panel types: 1” and 1½” nail strip (fastener flange), 1” and 1½” snap-lock, and 1” and 1½” mechanically seamed standing seam panels (essentially covering five profile configurations). The Z-Panel has an infinitely adjustable width from 12″ to 24″ coverage, which means you can dial in any panel width in that range without changing spacers – a nice versatility for custom jobs. It uses an electric drive (110V, 1.5 HP) with a hydraulic-powered shear, and can run steel up to 24 gauge, .032″ aluminum, and 20 oz copper, which covers typical residential material needs. Its output speed is roughly in the 35–45 ft/min range, standard for an electric-powered machine of this class.

Zimmerman machines are known for heavy-duty construction – for example, their frames are built from 2″ welded tubular steel and they use stainless steel forming rollers for durability. Tooling changeovers are designed to be straightforward; Zimmerman notes that an advanced design allows profile tooling change in about an hour on their machines, comparable to other multi-profile systems. For contractors who prefer equipment emphasizing build quality and specialty commercial functions, Zimmerman’s portable rollformers are an attractive option.

While Zimmerman provides service and training, they’re only available at their Denver, Colorado facility.

Comparison of Key Machine Features

The table below summarizes key features of portable rollforming machines from each manufacturer discussed:

| Manufacturer | Max Profiles | Max Speed | Power/ Drive System | Standout Features |

| Bradbury Group | Multiple (rafted tooling) | ~100 ft/min | Electric/hydraulic | Automated controls, integrated mastic, rafted tooling |

| Englert Inc. | 9 profiles (MetalMan Multi-Panel) | 90 ft/min | 13 HP gas/hydraulic | Full support package. Also offers single-profile machines for dedicated use. |

| New Tech Machinery | 16 profiles (SSQ II) | 75 ft/min | Gas/electric (Quick-Change™), gear/chain drive | Optional built-in notching system. Free in-house training for new owners and phone and in-field support |

| Roll Forming Corp. | 7 profiles (VS-150 Panformer) | ~40-50 ft/min | Electric-hydraulic, chain/sprocket drive | Quick tooling swaps, versatile profile options, rugged build, automated length controller |

| Schlebach GmbH | ~10-11 profiles (Quadro series) | 46 ft/min | Electric drive, dual-drive system | Fast cassette profile swaps, precision engineering, inline notching |

| Zimmerman Metals | 5 profiles (Z-Panel machine | ~40 ft/min | Electric (110V), hydraulic shear | Minimized oil-canning, heavy-duty U.S.-made construction |

Factors to Consider

Cost is typically the first consideration when comparing portable rollformers, but cost involves more than just the sticker price. Buying cheaper machines or sourcing parts internationally might save money upfront but can lead to expensive delays and downtime in the long run.

Reliable support is critical to keeping your jobs running smoothly. Ensure your machine manufacturer offers responsive service and technical expertise when you need it. At NTM, we provide phone support during business hours, field technicians, in-house and on-site servicing, and a full library of how-to videos and articles online, helping contractors quickly resolve many machine-related issues.

Ultimately, machine quality matters most—you often get what you pay for. Look for customer testimonials and real-life videos that showcase equipment performance. NTM proudly shares stories and videos from contractors using our machines on job sites, giving you direct insight into the value we provide.

We understand you have options in portable rollforming machines. Contact us if you have questions or want to learn what sets New Tech Machinery apart. Our expert account managers are here to help.