S-5! Snow Guards for Metal Roofs – An In-Depth Review

For over 30 years, S-5! has been the premier provider of snow guard systems for standing seam and exposed fastener roofs in the metal roofing industry. In this article, we’ll explore what makes S-5! different, compare their systems, and examine their product engineering.

A snow retention system is designed to manage how snow and ice accumulate, helping prevent large, sudden slides. Because metal roofs can be especially slick in cold, snowy conditions, these systems are critical in areas with significant snowfall. By holding or gradually releasing snow, they reduce the risk of damage to gutters, landscaping, and anything (or anyone) below.

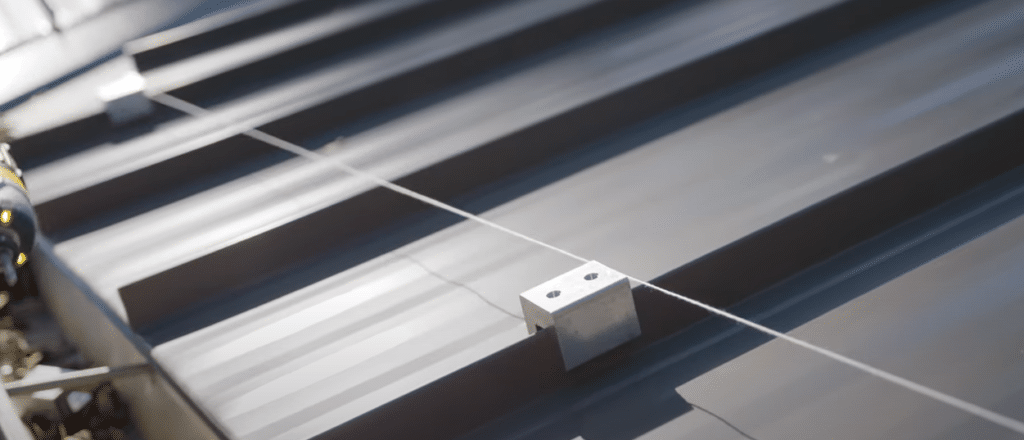

On standing seam metal roofs, engineered snow guards and rail systems commonly attach using specialized clamps—no drilling required—so the roof’s integrity stays intact. Overall, a well-chosen snow retention system ensures that winter weather doesn’t lead to dangerous situations or costly repairs, like replacing a gutter system.

S-5! founder and CEO Rob Haddock started the company in 1992 when after operating as a contractor and then a consultant, he realized the need for metal roofing solutions. The business began by developing snow guards, service walkways, attachments, and more.

Engineering

Making a choice between snow guard systems may start with engineered vs. non-engineered:

• An engineered snow guard system is tested to meet specific load requirements, taking into account factors like local snowfall totals, roof slope, panel type, and overall structural integrity. Because it’s backed by data and testing, it typically comes with detailed installation instructions, performance ratings, and often a warranty based on its certified capabilities.

• A non-engineered snow guard system, on the other hand, may rely on general guidelines or rules of thumb rather than precise calculations. While often less expensive upfront, these systems aren’t always backed by formal testing or engineering data. As a result, they may not reliably handle heavier snow loads or unique roof conditions.

S-5! only offers engineered systems. “We load-test all of our clamps and we do it in a certified laboratory,” explains Shawn Haddock, S-5! Vice President of Operations. “The engineering is due diligence on our part, so we’re putting out products that we know will continue to function for the life of the roof.”

S-5! has often collaborated with NTM for panel testing. “S-5! and New Tech Machinery have a relationship that spans decades,” Shawn said. “I was constantly testing all these panels and then wondered who was manufacturing them. It turns out, they’re coming from a New Tech machine. So, we got with New Tech and started testing all their profiles and publishing the results.”

From there, the relationship evolved. “Over the years, I’ve met quite a few people at New Tech and gotten to know everybody. And we have a great relationship,” said Shawn.

While S-5! provides numerous products and services, in this article we will focus on snow guards, including:

- A comparison of different snow guard models for standing seam roofs

- Industry regulations and standards

- Installation and best practices

- Additional snow retention system manufacturers

Comparison of S-5! Snow Guard Models for Standing Seam Roofs

S-5! produces engineered snow guard systems to hold snow in place so it melts or sheds gradually. These snow retention systems clamp onto standing seam or exposed fastener roofs without penetrating the metal roof, preventing leakage and corrosion.

These snow retention systems are designed specifically for metal roofs, ranging from continuous bar systems that run along the roof eave to discrete two-pipe “fence” systems or slender rod systems for more architectural applications.

Below is a comparison of the key S-5! models, including their intended use, materials, performance, and aesthetics:

• ColorGard® 2.0 is a continuous aluminum bar system that matches the color and roof material (ColorStrip). It’s compatible with virtually any standing seam profile and can also work on exposed-fastened roofs using the right S-5! brackets. It’s constructed of non-corrosive aluminum and stainless steel. ColorGard is lightweight, durable, maintenance-free, and easy to install.

ColorGard’s continuous rail design evenly distributes the weight of any snow load while blending into the roof. Since you use the same material strip as the roof finish, the bar practically disappears from view, which is a great advantage for owners concerned with the appearance of their homes.

ColorStrip™ should be supplied by the manufacturer of the roofing material to match the color of the roof.

S-5! also stands behind ColorGard with a limited lifetime performance warranty that matches the life of the roof, as both are made from the same material.

The newly released Colorgard 2.0 simplifies installation thanks to its internal splice sleeve and the VersaClip™ system. No on-site cutting is required, making it a “lay-and-play” application for both standing seam and exposed-fastener roofs.

• X-Gard™ 1.0 can be designed as a one or two-pipe snow bar system that uses S-5!’s 2” diameter *NEX® aluminum crossmember. Its octagonal shape delivers better beam strength than a round tube, allowing spans of up to 4’ between attachments. This makes X-Gard 1.0 ideal for heavy snow loads and wide-seam roofs.

It’s especially well-suited for insulated metal panel (IMP) roofs with 36″–48″ seam spacing, where the bar can cantilever up to 20″ beyond the final clamp if necessary. Despite its heavy-duty performance, you can still use fewer clamps for sites with lower snow loads—making it robust while saving you money. Like other S-5! solutions, X-Gard 1.0 installs without penetrating the roof, preserving warranties and maintaining roof integrity.

The system can be powder-coated or painted to match your roof’s finish, and optional X-Clip™ brackets help stop meltwater from creeping under the bar during freeze-thaw cycles. For applications requiring even more capacity, S-5! also offers the two-pipe X-Gard 2.0 system.

• X-Gard™ 2.0 is the two-pipe version of the X-Gard system, built for extremely heavy snow loads. It uses two parallel NEX® 2″ pipes held by brackets that clamp onto each seam with a double-clamp, distributing the force across two seam clamps per bracket. This design is perfect for alpine areas or insulated metal panel (IMP) roofs with wide 36″–48″ seam spacing, where a single-seam attachment may not be enough.

The dual pipes sit roughly 7″–9″ above the roof surface (depending on seam height), providing a tall “fence” for managing deep snow. Even though it’s built for tough conditions, X-Gard 2.0 is still a non-invasive clamp system, preserving your roof warranty by avoiding through-fasteners.

Manufactured from high-tensile aluminum and stainless hardware, X-Gard 2.0 can be powder-coated, painted or anodized to blend with the roof. Its octagonal pipes prevent rotation and add strength, allowing spans of up to four feet between supports and the option to cantilever up to 20″ beyond the last clamp if needed. As S-5!’s top-tier snow guard system, X-Gard 2.0 is a strong choice for long-span roofs in heavy snow country or for roofs with solar panels that need extra snow clearance.

• DualGard™ is a two-pipe, 1″ diameter aluminum snow guard system that works great on both standing seam and through-fastened (corrugated) metal roofs. It’s similar to the X-Gard 2.0 two-rail “fence” setup but uses smaller pipes and components.

In terms of applications, DualGard is an all-purpose option for medium to high snow loads when you want the extra protection of a two-bar system.

On standing seams, each DualGard bracket attaches with two S-5! mini clamps instead of just one. This gives you a broader base of attachment for extra holding strength, reducing torque on each seam and improving lateral stability. For corrugated (exposed-fastened) panels, you can swap the clamps for S-5! CorruBracket™ hardware.

From a materials and aesthetics standpoint, DualGard is made entirely of aluminum and stainless steel, and it can be powder-coated or anodized to match the roof. It’s marketed as a more affordable two-pipe fence—averaging around $12–$17 per foot—compared to the heavier X-Gard 2.0, yet it’s still engineered and tested for site-specific loads using S-5!’s calculator and load test data.

If you’re looking for the performance and look of a twin-pipe snow fence, combined with reliable clamping strength and cost-efficiency, DualGard might be the right fit for most building applications.

• SnoRail™ is a single-rod snow guard that offers a sleek, architectural look for areas with light to moderate snow. Instead of bulkier pipes, SnoRail uses a slim 3/8″ stainless steel rod, elevated a few inches above the seam by small clamp-on posts. This minimalist design is popular with architects because it’s less noticeable on high-end or historic roofs.

Typical applications are architectural standing seam roofs where appearance is a priority and snow loads aren’t too extreme. SnoRail is available in two material choices: aluminum/stainless for steel, aluminum, or zinc roofs, and all-brass for copper or lead-coated copper roofs. The brass option helps prevent galvanic corrosion and blends nicely with the natural copper patina.

Because of the rod’s smaller diameter, SnoRail is best suited for light to medium snow retention—it’ll manage smaller slides and let snow gradually release, but for heavier snowfall or long roof spans, a stronger system like DualGard™ or X-Gard® is usually recommended. According to S-5!’s guidelines, SnoRail clamps should be spaced no more than 24 inches on center (or closer if the loads demand). Its simple design and relatively low cost (starting around $6.50 per foot installed) make SnoRail a go-to choice for homeowners or projects that need reliable snow holding without the bulkier look of a heavy-duty system.

SnoFence™ is basically the two-rod version of SnoRail™, best for medium-duty applications where you want more stopping power without sacrificing a sleek look. Instead of just one 3/8″ rod, SnoFence adds a second rod about two inches above the first, creating a double-rail fence that can handle heavier snow and ice loads while still maintaining a low profile.

This system is popular among architects who need a bit more protection than SnoRail provides but insist on a streamlined appearance. Like SnoRail, it comes in aluminum/stainless for most roofs or brass for copper roofs, helping prevent corrosion and match the roof’s finish. The added rod is especially helpful for catching ice chunks, making SnoFence reliable for periodic heavy snows when a larger pipe-style system might not be an option.

SnoFence installs just like SnoRail: clamps are typically spaced at around 24 inches, and there’s no roof penetration. Prices start at about $11 per foot for the aluminum version, so it’s a solid choice for high-end homes, churches, or historic buildings where you need both form and function.

Industry Regulations, Standards, and Best Practices

When adding snow retention to a metal roof, it’s important to consider building code requirements, structural design standards, and industry best practices. While specific codes for snow guards are often minimal, the following points summarize the relevant regulations and guidelines:

Snow Load Design & Building Codes: What You Need to Know

Although the International Building Code (IBC) doesn’t explicitly require snow guards in most situations—there isn’t a direct code section mandating the prevention of sliding snow—it does require that roofs support snow loads as determined by ASCE 7. When you install snow guards, keep in mind you can’t assume snow will just slide off the roof. ASCE 7 allows reduced design snow loads for slippery roofs with no obstructions, but once you add snow guards, you have to design for the full ground snow load (and possibly more if you’re in a drift-prone area).

That means the entire roof structure—purlins, clips, connections—must be designed or checked to handle the added weight of retained snow plus any drifting. For retrofits on older buildings, it’s crucial to verify that the roof wasn’t originally relying on snow shedding to reduce loads. If so, the structure may need reinforcement before you add a snow retention system.

In some regions with heavy snowfall, local amendments or guidelines effectively require snow retention or other protective measures (like canopies) over public entrances. Even if it’s not spelled out in the model code, many jurisdictions or project specs want to ensure there’s no snow dumping onto pedestrians. Always check local building ordinances and owner requirements.

In the end, ASCE 7-16/22—referenced by the IBC—governs how we calculate and distribute snow loads. If you’re using snow guards, just make sure you account for their impact on your overall load design. This helps you stay code-compliant and keeps everyone below your roof safe.

• OSHA/Safety Regulations: There are no direct OSHA rules about snow guards on roofs (OSHA deals more with worker safety on roofs), but building owners have a liability to prevent foreseeable hazards – which can include snow falling onto entries. In some cases, insurance companies or risk managers will require snow retention on metal roofs over critical areas as a risk mitigation measure. This isn’t a code per se, but it is part of the “standard of care” in building design for safety.

Some of those standards are produced by MCA or the Metal Construction Association,” Shawn Haddock explained. “They provide technical documents, one of which is called metal roof design for cold climates. And then there’s another called qualifying Snow retention systems for metal roofing. These are documents that designers and people can use for snow retention. In addition, IAPMO (International Association of Plumbing and Mechanical Officials)* has recently come out with evaluation criteria for snow retention systems. So, the industry is progressing towards codes, but right now, there really aren’t any except maybe in some local government areas.”

Thus, architects often include notes in plans that say “provide snow guards above all pedestrian areas” in snowy climates, even if not dictated by code. Failing to do so could be seen as a design omission if injuries occur. The snow guard industry often markets their products as “life safety devices”, and indeed Metal Construction News notes that “Sudden release from a rooftop can dump tons of snow below the eaves in a matter of seconds, endangering building elements, landscape, vehicles, and pedestrians. In this sense, the use of snow retention devices and systems should be considered nothing less than a life-safety issue.”

This perspective aligns with treating snow retention as part of the building’s safety features.

*”S-5! is the first and only company to receive an Evaluation Report (ER) from the International Association of Plumbing and Mechanical Officials (IAPMO), certifying its snow retention systems’ compliance with Evaluation Criteria (EC) 029-2018 for Standing Seam Metal Roof-Mounted Rail-Type Snow Retention Systems.” Building Enclosure (BE)

MCA Technical Standards: Choosing the Right Snow Retention System

When it comes to metal roofing and snow guards, the Metal Construction Association (MCA) has some technical bulletins you’ll want to consult. One key resource is “Qualifying Snow Retention Systems for Metal Roofing.” This bulletin lays out how to pick a reliable system, emphasizing the importance of load testing on the specific roof panel type. The manufacturer should supply data proving their product’s performance, and the MCA recommends you confirm three main things:

o Load testing for the exact roof panel configuration

o Non-corrosive, compatible materials

o Proven track record or industry-standard compliance

The MCA also clarifies differences between continuous rail-style systems and individual cleat-type guards; you’ll need to evaluate which is best for your project. Another important MCA publication is “Metal Roof Design for Cold Climates,” which offers best practices on everything from snow guard placement near the eave to adding additional rows upslope as needed.

Load Testing & Certification: Because there’s no dedicated ANSI or ASTM standard for snow guards, manufacturers shoulder the responsibility for comprehensive testing. Many project specs call for systems with independent lab testing or even engineer-stamped letters confirming allowable loads on a specific roof type. Some manufacturers, like S-5!, offer a project-specific P.E. stamped report to verify that the system meets structural requirements.

In certain regions (e.g., high-snow areas), you may even need documentation showing that a snow retention system can hold a specified amount of force—especially if it’s viewed as a safety measure. Generally, you’ll follow the tested limits with a healthy safety factor. S-5!’s guidelines typically include at least a Factor of Safety of 2 on ultimate test loads. ASCE 7 also implies built-in safety margins through load combinations, which is why using a tested system with known failure loads is so crucial for staying compliant and maintaining performance.

Roof Manufacturer Approvals: Most major roof manufacturers—like Butler, Varco Pruden, Morin, Englert, and others—offer guidelines for installing snow guards on their roof systems. A common theme is avoiding penetrations that could lead to leaks or compromise warranties, which is why non-invasive clamp attachments (like those from S-5!) are widely recommended. Many manufacturers actually list specific “acceptable snow retention products,” and S-5! often makes the cut thanks to its proven performance and broad endorsements (including some co-developed, color-matched part numbers).

The main takeaway? Always check the roof manufacturer’s guidelines to confirm the snow guard system won’t void any warranties. With S-5!’s clamp-on approach, you’re generally good to go, but you might see recommendations about where to place clamps—usually near panel clips, so the loads are transferred directly into structural supports. S-5!’s load testing on various roof profiles already accounts for clip spacing and panel properties, so following their spacing guidelines typically aligns with what roof manufacturers require.

Building codes require roofs to carry snow loads, but they don’t specify whether you should retain or shed snow. Snow guards often come down to safety and owner preference rather than a hard-and-fast code rule. Still, once you commit to snow retention, standards like ASCE 7 and the MCA’s guidelines expect a properly engineered, tested system.

Many contractors see engineered products like S-5! as the industry standard. It’s also an easy name to remember, but when asked, even Rob Haddock’s family, who work at the operation, don’t know why he chose that name. “It’s a secret he’ll take to his grave,” said Shawn Haddock. Jessica Haddock confirmed that. “I have a theory,” she said, “that the “S” stands for solution, since Rob is very solution-oriented, and 5 is for the number of children he has. But no one knows for sure, and I don’t think we ever will.”

Whatever the meaning, S-5! has become the go-to for metal roofing solutions for contractors across the country.

S-5! and New Tech Machinery have a relationship that spans decades,” Shawn said. “I was constantly testing all these panels and then wondered who was manufacturing them. It turns out, they’re coming from a New Tech machine. So, we got with New Tech and started testing all their profiles and publishing the results.

S-5! Value and Quality

The testing and engineering that go into the S-5! snow retention systems help guarantee their longevity. Similar products that use plastics and glues tend to degrade over time.

“Our mission is to be one of the most affordable and best systems on the market,” said Shawn Haddock. “And at 99% of jobs, we’re exactly that. So where people think we’re expensive is they’re not doing the engineering, but if you look at that one part that’s going to hold 500 lbs. today and 75 lbs. in five years. ColorGard will hold 1500 lbs. for the life of the roof.”

Installation

S-5! Installation Challenges and Solutions

Installing an S-5! snow retention system on a standing seam roof is straightforward for experienced contractors, but there are still some common pitfalls to avoid. S-5! and industry experts provide guidance to ensure a smooth installation and long-term performance:

• Choosing the right clamp for your standing seam is essential since profiles vary widely—double-lock, snap-lock, T-seam, bulb seam, and more—each with its own thickness. S-5! offers a range of clamp models (S-5-U, S-5-S, S-5-T, S-5-N, etc.) designed to match these different seam types, but the trick is figuring out which one fits your particular roof. Using the wrong clamp can cause a poor grip or even damage the seam.

“We came up with the use of a round point set screw and that round point set screw allows you to attach a clamp to a panel without doing any damage to that roof panel,” Shawn explained.

S-5! provides selection charts and an online Project Configurator to guide you. Just input the roof manufacturer and seam profile to find the recommended clamp type and quantity. Make sure to check your actual seam dimensions against the clamp specs (such as throat size and flange width) for a perfect fit.

If you’re working with copper roofing, use S-5!’s brass clamps (like the S-5-BSF) to avoid galvanic corrosion and ensure a better grip on the softer copper material.

Ultimately, matching the correct clamp model—and using the right number of them—is the first step to a successful installation.

• Planning the Layout and Spacing: Another mistake is “eyeballing” the placement or number of snow guards. The capacity of a snow retention system depends on how many rows of guards are used, how far up the roof they’re placed, and the spacing of the brackets/clamps along the eave.

Use the S-5! Snow Retention Calculator or follow an engineer’s plan to determine the exact layout This calculator (freely available on S-5!’s website) takes into account the roof length, pitch, snow load (per ASCE 7), panel type, and even factors like roof exposure and importance. It will output how many rows of snow guards you need (some long roofs may require 2 or 3 staggered rows, not just one at the eave) and how close the clamps should be spaced for the given loads.

Relying on this site-specific engineering ensures the system will hold. S-5! emphasizes that snow guard design shouldn’t be guesswork—their tool is meant to ensure the right coverage. A best practice is to always install the full number of units called for by the calculation (don’t skimp to save cost) and distribute them evenly as instructed.

For example, the SnoRail and SnoFence systems typically specify a maximum 24″ clamp spacing; heavier snow areas might require dropping that to 18″ or 12″ spacing. Following these spacing guidelines is critical so that no single clamp or panel section is overloaded. Proper layout planning also involves positioning the first row of snow guards a short distance upslope of the eave (usually a few inches in from the drip edge) so melting snow and ice will run off into gutters while the bulk of the snow stays behind the guards.

Correct set screw tension is crucial to S-5! clamps to get their maximum holding strength.

According to Shawn Haddock, “When it comes to our products, some of the most common problems I would see with installation are that contractors are a little bit nervous to get the set screw as tight as it should be. They’re afraid they’re going to do damage to the panel and what they really need to do is be sure that they’re achieving the right torque so they get the right holding strength out of our products.”

Under-tightening can cause slips, and over-tightening can strip threads or crush the seam. To avoid these issues, follow S-5!’s torque specs for the clamp model you’re using—most commonly 130–150 inch-pounds, though heavier gauge panels may require a higher torque. Check the specific instructions to be sure.

Use a properly calibrated torque wrench or adjustable torque-impact driver, and don’t forget to periodically spot-check clamps to make sure torque remains within the recommended range. S-5!’s tests confirm that adequate tension is key to each clamp hitting its full capacity. Many installers mark each clamp after torquing for peace of mind. By sticking to the correct torque guidelines, you’ll ensure your clamps stay locked in place when the snow piles up.

One major advantage of S-5! snow guards is their year-round installability—because they rely on mechanical clamps rather than adhesives or chemicals, they’re not dependent on warm, dry conditions. Traditional stick-on guards often fail on slick PVDF (Kynar®) finishes and don’t bond well in cold weather. With S-5!, you just brush away the snow, remove any frost or ice from the seam, and clamp. The serrated interior of the clamps ensures a solid bite even if there’s a thin film or residue on the metal.

This flexibility is a big plus for contractors: you can install or retrofit whenever you need to, without waiting for a sunny day or warmer temperatures. If a roof is finished in late fall, you can add snow guards immediately instead of waiting until spring. Mechanical attachment is simply more reliable than adhesives on today’s nonstick paint systems, which often see high failure rates.

On longer roofs—or extended runs of snow guard rail—it’s important to allow for the natural thermal expansion of the metal. A 100-foot aluminum rail can expand quite a bit from summer to winter, and if there’s no room for movement, the rail could buckle or a clamp may come loose over time.

S-5!’s systems are designed to handle this. ColorGard® 2.0, for instance, uses the VersaClip™ to let the bar float, plus internal splices that allow a small gap for expansion. With SnoRail™/SnoFence™, you’ll use an “anchor” clamp (S-5-AE™) to keep the rod fixed, while the other clamps let the rod slide as it expands or contracts. Usually, you anchor from the center (or one end) and let it expand outward in both directions.

Alignment matters, too—on long eaves, you’ll want to ensure all your clamps line up so the rails or rods look straight. ColorGard 2.0’s design makes this simpler by allowing continuous lengths of bar (7’8″ each), and the VersaClips can be placed wherever you need along the bar, even over splice joints. That way, you don’t have to pre-cut pieces to align with each seam.

In short, use the provided splices, anchor points, and sliding clips to accommodate thermal movement, and make sure your clamp line is nice and straight before torquing everything down. This ensures a neat, continuous installation that stays solid through seasonal temperature swings.

After installation, it’s easy to skip a final walk-through, but a quick inspection can save a lot of hassle later. Check that each set screw is properly torqued, every splice or end cap is secure, and that no clamps end up on a damaged or overly flattened seam. If you spot a seam that’s really banged up, just shift the clamp to a better area.

Don’t forget to check that any SnoClips or X-Clips—if required—are correctly placed between the seams to prevent snow from creeping underneath the rail. From there, let the building owner know that these guards need very little maintenance—unlike heated cables or other more complex systems. It’s still smart to include them in routine roof checks. And if the roof sees a massive snow event, a quick look afterward is a good idea.

Finally, keep in mind that S-5! systems are modular. If the building gets an addition or roof panels need replacing, the snow guards can be removed and reinstalled or expanded as needed.

By following these best practices—choosing the right clamp, spacing everything properly, setting the correct torque, using weather-independent methods, and accommodating thermal movement—contractors find S-5! snow guards “simple and easy to install,” just as promised. The systems are designed to overcome the common headaches of older snow guard methods.

In fact, one roofer featured in an S-5! case study said, “ColorGard is well-made, durable, simple and easy to install… designed to last the life of the roof.” Just stick to the manufacturer’s guidelines.

Installation Steps

Make sure to follow the manufacturer’s installation instructions for your snow guards. Determine the spacing and placement ahead of time, and whenever possible, preassemble the system components before you start the installation.

Here’s a step-by-step approach for installing a snow retention system:

- Establish Reference Points

- Measure from the eave at both ends of the intended row.

- Mark these points and attach a string line between them to ensure a straight row.

- Mount Seam Clamps

- Align each clamp with the string line.

- Follow the manufacturer’s recommended set screw torque—this is critical for achieving published load values.

- Calibrate your tightening tool to the specified torque and perform periodic checks to ensure it remains accurate.

- Note on Torque Wrenches: In most “soft joint” applications, clicker torque wrenches are unsuitable. A dial-indicating torque wrench is strongly preferred.

- Fasteners for Exposed-Fastener Systems

- Confirm the fasteners you use match or exceed the expected service life of those recommended by the roof system manufacturer.

- Published load values only apply if you use the exact fastener tested by the manufacturer.

- Use fasteners appropriate for the specific substrate (e.g., steel purlin vs. wood deck). If the manufacturer doesn’t have test data for your exact substrate and fastener combination, those load values won’t apply to your project.

- Install Cross-Members

- Complete a continuous system by attaching the cross-members.

- If you’re using multiple cross-members, offset their splices (e.g., don’t splice the top member over the same span as the bottom).

- Add Secondary Components

- Attach end caps, collars, snow clips, and any other accessories as directed by the manufacturer.

- These components often play a critical role in the system’s performance, so don’t skip or overlook them.

- Follow Manufacturer Instructions

- Carefully read and follow the manufacturer’s full installation guidelines.

- Plan your layout, ensure straight rows, and confirm correct torque on set screws.

- When attaching to the structure, only use manufacturer-tested fasteners.

By taking these steps and adhering to the manufacturer’s recommendations, you’ll ensure a properly installed, effective snow retention system.

When it comes to our products, some of the most common problems I would see with installation are that contractors are a little bit nervous to get the set screw as tight as it should be,” said Shawn Haddock. “They’re afraid they’re going to do damage to the panel and what they really need to do is be sure that they’re achieving the right torque so they get the right holding strength out of our products.

Additional Snow Retention System Manufacturers

While S-5! has stood out as the leader in snow retention systems, several other companies have established solid reputations, so it’s worth making some comparisons.

When comparing S-5! to other snow retention brands, it’s important to note that all these companies produce reliable products for metal roofing. That said, there are a few typical quality differentiators you might notice:

- Engineering & Testing

- S-5! is known for robust engineering, extensive load testing, and highly specific product fitment for different standing seam profiles. Their clamps often have strong published test data and proven performance over decades.

- Other companies (like AceClamp®, Berger®, and Alpine SnowGuards®) also offer engineered systems, but the extent and transparency of testing can vary. While some publish product performance data, others provide generalized or no details. Check the manufacturer website or contact them directly for information on engineering and testing prior to purchasing their products.

- Materials & Construction

- S-5! primarily uses high-grade aluminum and stainless steel hardware for durability and corrosion resistance.

- SnoBlox-Snojax™ is well-known for pioneering polycarbonate pad-style guards, while companies like SnoGem also use polycarbonate alongside metal systems. Polycarbonate snow guards can be strong and cost-effective, but some users prefer metal for longevity and color matching.

- Rocky Mountain Snow Guards® and Alpine SnowGuards both work with a variety of materials (aluminum, stainless steel, copper, polycarbonate) and often offer custom solutions based on project needs.

- Mounting Method & Design

- S-5!’s clamp-to-seam design is straightforward and does not typically require roof penetration, preserving warranties. They also offer bar-style and bracket systems.

- AceClamp and SnoGem® produce similar clamp-to-seam options that can be installed without penetrating the roof panel.

- Berger and Alpine SnowGuards provide both clamp-to-seam and traditional “pad-style” guards (which may require mechanical fastening). Quality is still high, but installation complexity can differ based on the product line.

- Product Range & Customization

- S-5! focuses on refined lines of clamps, rails, and accessories specifically for metal roofs, which can streamline selection.

- Alpine SnowGuards and Rocky Mountain Snow Guards specialize in custom and decorative snow retention options alongside standard offerings. If you’re looking for a unique aesthetic or color-matching solution, those brands might stand out.

- SnoGem and SnoBlox-Snojax offer a broad variety of polycarbonate and metal guards for multiple roof types, which some homeowners prefer if they need custom color matching or lower-profile designs.

- Warranty & Support

- S-5! typically provides warranties tied to the quality of their aluminum clamp designs; these warranties can vary in length but are known to be robust.

- Competitors will have their own warranties—generally shorter or more limited than S-5!’s, depending on materials, hardware, and finish. Always compare warranty specifics, including any conditions about installation or product combinations.

- Price Points & Value

- S-5! can sometimes be more premium-priced compared to basic options, but this often corresponds to their engineering pedigree and proven track record.

- Other companies may offer cost-effective solutions (especially with polycarbonate guards), but the ultimate value depends on your roof type, climate demands, and longevity expectations.

Overall, S-5! emphasizes strong, well-tested, non-penetrating clamp systems with excellent materials and a long history in the market. Competitors might offer more specialized designs, broader aesthetic choices, or cheaper solutions, but may not always match S-5!’s track record for thorough testing and long-term performance.

For contractors, S-5! provides a well-documented path to installation – with calculators, instructions, and support – which addresses common challenges and leads to successful outcomes. And for the wider industry, these systems align with codes and standards by enhancing roof safety and longevity. Their engineering is based on New Tech Machinery panels, so their snow retention products are a great fit for our standing seam and exposed fastener systems. That said, other compatible products exist in the market. The “best” choice often comes down to project needs, roof profile, budget, and personal preference on design or materials.

New Tech Machinery released its first portable roof panel machine in 1991. Our advanced portable rollformers the SSQ II™ MultiPro, SSH™ MultiPro, and SSR™ MultiPro Jr., offer multiple standing seam profile options. For information on our portable metal roof and wall panel machines, or seamlesss gutter machines, contact us.