Mechanical seam and snap-lock metal roof profiles are the two most common styles used in residential and commercial standing seam roof systems. However, how much do you know the differences between them? What are the advantages and disadvantages of using mechanical lock vs. snap-lock metal roof profile?

At New Tech Machinery (NTM), we manufacture portable roof panel machines designed to make standing seam panel profiles including both of these popular metal roof panel profile styles. We understand the importance of researching what makes each of these profiles unique, including the pros and cons of each kind of profile so that you can select the best profiles for your machine and projects.

Understanding the characteristics, advantages, and disadvantages of these types of panel profiles can help you decide what profile is the best option to use on your next metal roofing project.

In this article, we’ll cover:

- The characteristics of mechanical lock profiles and snap-lock profiles

- Advantages and disadvantages of using mechanical lock and snap-lock profiles

- What to consider to help you figure out which profile to use on your project

What Is a Mechanical Lock Panel Profile?

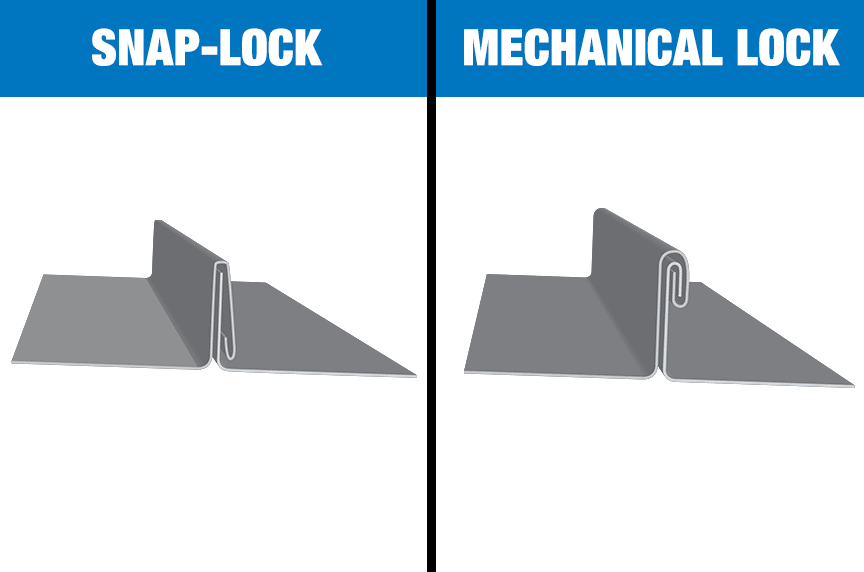

Mechanically-seamed metal roofs have vertical legs that line up with each other and are seamed together with a hand or electric seamer. Using an electric seaming tool can allow for a tighter and more consistent seam than just hand-forming them. The concealed clips are then a part of the mechanical lock system. Often, mechanical seam profiles require expansion clips to account for the panel’s thermal movement.

Two types of mechanical seam profiles used on standing seam metal roofs are single lock or double lock.

A single lock seam refers to the fact that there’s only one fold of the seam so it’s a 90-degree seam. Some of the benefits of using a single lock profile are that they take less labor to install and are easier to replace should damage occur than the double lock alternative.

Double lock seams are those that have been folded over twice (or 180 degrees). They are better used for low-slope building applications that may need to be extra weathertight. One consideration to make when using this type of panel is that they are more labor-intensive to install and replace.

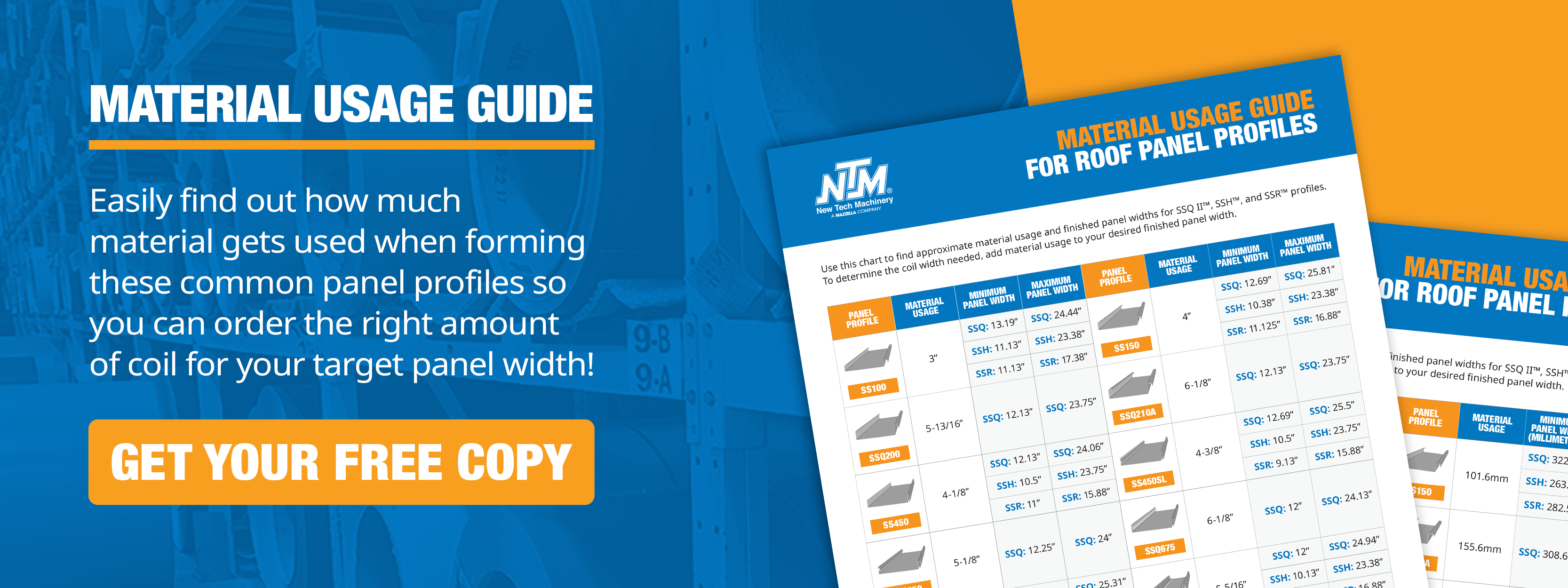

Mechanical lock profiles available with New Tech Machinery’s SSH™ MultiPro, SSR™ MultiPro Jr., or the SSQ II™ MultiPro Roof Panel Machines include the following (however not all machines can produce every profile):

- SS100 (1″ mechanical seam profile)

- SS150 (1.5″ mechanical seam profile)

- SSQ200 (2″ mechanical seam profile)

- SSQ210A (2″ ARMCO style mechanical seam profile)

Advantages of Using Mechanical Lock Profiles

Can be used for lower slope roofs – One advantage of using mechanical seam panel profiles is that you can use them on low slope buildings (those of 2/12 pitch and less) unless otherwise dictated by the project specifications or panel design limitations. Usually, a seam sealant will be required when going below a 2/12 pitch. Please check with the manufacturer for the minimum pitch they recommend.

Varying seam heights – Since this type of standing seam profile is seamed mechanically in the field, they can have varying seam heights, typically 1″, 1.5″, and 2″.

Better watertight capabilities – On low slope roofs, especially, the potential for water remaining on the roof can be problematic. In this instance, using a mechanical lock profile would be best since the way that these panels are seamed together allows for more watertight and waterproofing capabilities.

Using a seaming tool for installing mechanical seam profiles keeps the seam tightly closed, and thus closes the spaces where water might collect and reduces the chance of leaking into the roof structure. A sealant can also be added to the panels’ legs to further assist in waterproofing the roof.

Durable and strong profile – The way these panels are mechanically seamed together adds rigidity to the structure and makes them even stronger against high winds and hazardous weather.

Disadvantages of Using Mechanical Lock Profiles

More labor-intensive and costly – Due to the hand crimper or electric seamer needed to connect the mechanical lock panels together, this style can be more labor-intensive to install and more expensive. While some companies might want to purchase their own seamer, you can also look into renting one, saving you from a large upfront investment.

Potential problems while seaming or unseaming panels – One possible issue with using a seaming device for this profile is that the seamer may jump and damage the seam. If the seaming device is misused or out of adjustment, it can cause costly damage to the seam or metal panel. It’s all preference on whether installers like to use hand seamers or electric, but knowing how to use the tool properly is the first step to avoiding potential problems.

Another potential issue is the “telegraphing” of the metal roofing clips through the panel seams, showing where each clip is placed within the panel structure. Should you ever need to unseam a panel, there’s also the potential risk of cracking the material when unseaming the panel legs or while seaming them back together.

What Is a Snap-lock Panel Profile?

Snap-lock panel profiles are another very common type of standing seam panel profile. They are also rollformed into shape, either using an in-plant or portable rollformer, with a male and female leg which snap together. Unlike mechanical lock profiles, this type doesn’t utilize a seaming tool to connect the panel legs.

This profile is typically used on a roof slope of 3:12 and greater unless otherwise specified by the manufacturer. Snap-lock profiles are widely used on both commercial and residential buildings.

As stated in the Metal Construction Association’s (MCA) Metal Roof Installation Manual, snap-lock profiles use fasteners or clips to attach the metal panel to the roof deck, but the seams are snapped into place. However, it is crucial that the whole panel seam is securely snapped into place and fully engaged.

When forming snap-lock profiles with a portable rollforming machine, typically it takes more material because of the complexity of the panel legs and the bends required to ensure this panel profile snaps into place securely.

Snap-lock profiles you can make with New Tech Machinery’s SSH MultiPro, SSR MultiPro Jr., or the SSQ II MultiPro Roof Panel Machines include the following (however, not every profile will be available with each machine):

- SS450 (1.5″ Snap-lock profile)

- SS450SL (1.5″ Snap-lock profile)

- SSQ550 (1.5″ Snap-lock profile)

- SSQ675 (1.75″ Snap-lock profile)

Advantages of Using Snap-lock Profiles

No seaming tools necessary – This profile style has a male and female leg that just gets snapped together, so you don’t need any seaming tools to connect the panels.

Typically easier and faster to install – Since snap-lock profiles don’t require any mechanical seaming, this system typically requires less labor to install and is generally cheaper.

Disadvantages of Using Snap-lock Profiles

Must be securely snapped into place – Again, according to the MCA Metal Roof Installation Guide, it’s critical that you tightly snap and engage the panel seams for the most effective weather resistance, and so that they don’t disengage over time.

Restricted to steep slope roof applications – Snap-lock profiles are mainly used only on steep slope architectural building applications, those of 3/12 roof pitch and greater. The reason for restricting their use on steep slopes is that these style panels are designed to shed water, not hold water. You can add sealant into the legs of the snap-lock panels to assist in waterproofing the panel legs.

Considerations to Make When Deciding to Use Mechanically Seamed vs. Snap-lock Profiles

Do you want the option to offer snap-lock and mechanical seam profiles to customers?

Depending on the machine you may already have or are looking to purchase, all of New Tech Machinery’s portable roof panel machines have capabilities to make both snap-lock and mechanical seam panel profiles so you’re not limited in what you can offer to customers. Some roof panel machine manufacturers may only make single-profile rollforming machines, so utilizing a machine that can make multiple profiles and styles increase the kinds of projects you can take on and your customer base.

Also, for some of the profiles available with New Tech Machinery (like the SS100, SS150, SS450/SS450SL) all use the same left-side tooling. So, if you already had the 1″ mechanical seam profile (SS100), all you’d have to purchase is the right-side roller sets to make the 1.5″ snap-lock profile (SS450/SS450SL).

What’s the roof slope?

If you know whether the roof is a steep or low slope, that will help you decide which profile to use.

As we said before, mechanical lock profiles work best on low slopes since they are more water-resistant and less likely to leak between the seams. Use snap-lock profiles as a more cost-effective option on steep slopes where there’s less likely to be water ponding on the roof. Taller panel leg heights can also contribute to panel strength.

How labor-intensive and costly is the profile to use in metal roofing installation?

You should also consider how labor-intensive the process will be to install the panels onto the metal roof system and how much time it could take. The panel installation process for snap-lock profiles is relatively straightforward: attach the metal panel to the roof deck using fasteners or clips, and snap the panel seams together. However, with mechanical lock profiles, it requires a hand or electric seamer to bend the panel legs over each other. Not only is this process more time-consuming, but it is generally more expensive.

What is the weather and temperature like in the area?

Lastly, you need to think about what the weather is typically like in the region you’ll be working on the metal roof. If the area gets a lot of harsh weather, high winds, or cold and freezing temperatures, utilizing a mechanical lock profile is probably your best bet.

Final Thoughts

Both mechanical lock and snap-lock profiles are great options for standing seam metal roofing, but there are certain factors to consider when deciding which one to use or purchase for your portable rollformer.

After understanding the different characteristics of each profile type, advantages, and disadvantages, you’ll be better able to make the right decision for your project. Also, refer to the manufacturer for their recommendations as panels aren’t all made the same way.

With over 30 years of manufacturing portable roofing rollformers and equipment, New Tech Machinery knows how important it is to be an educated customer. We strive to provide our customers with educational and informative resources that can help them feel more confident.

If you have additional questions regarding standing seam panel profiles, or which profiles are available with NTM portable roof panel machines, feel free to contact us.