Pre-Cut vs. Post-Cut Rollforming Machines: Advantages & Disadvantages

Two main types of rollforming equipment, in-plant or portable, have different ways of cutting or shearing the panels. When considering rollforming machines, it’s important to know the differences between pre-cut vs. post-cut rollforming machines, which kinds of rollformers are each type, and the advantages and disadvantages of both options to make an informed purchasing decision.

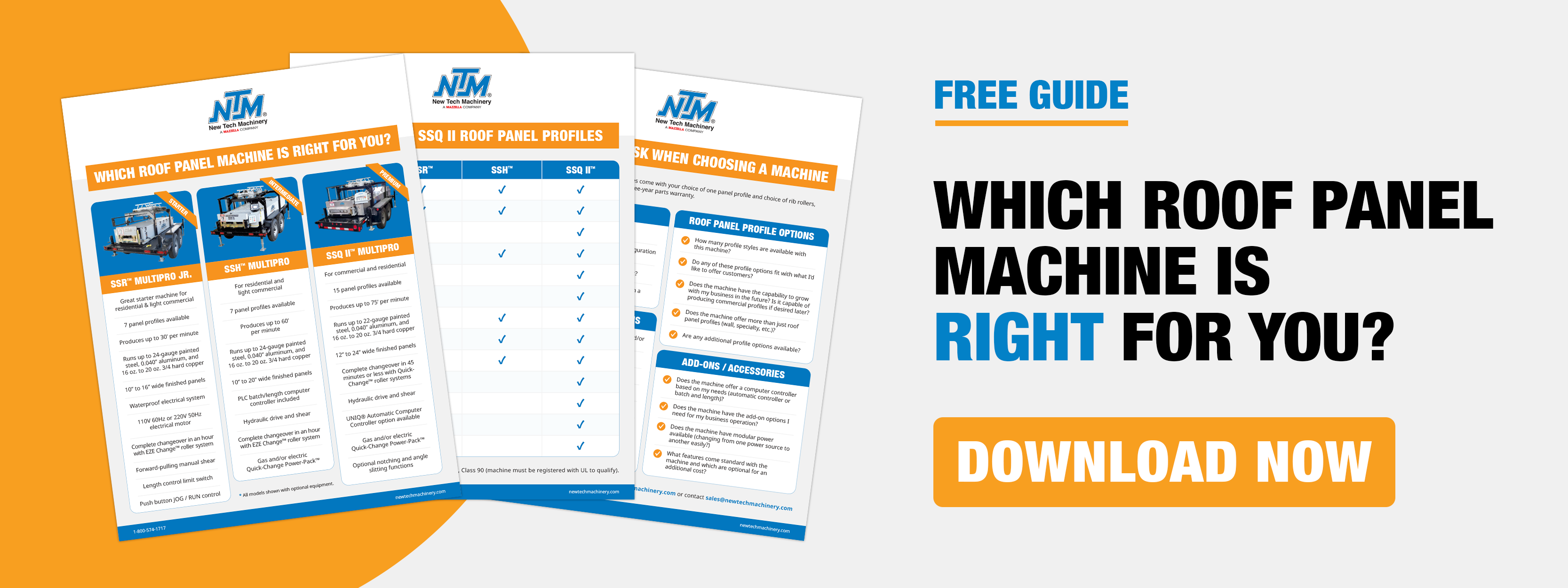

At New Tech Machinery (NTM), we manufacture portable roof panel rollforming machines that utilize post-cut shear. However, we understand that various rollforming machine types, both in-plant and portable, may be better suited for your metal roofing operation.

This article will explain pre-cut and post-cut rollforming machines, how they work, and the advantages and disadvantages of both kinds of equipment.

What Is a Pre-Cut Rollforming Machine?

Pre-cut rollforming means that the sheet metal is cut to length by the shear or cutting mechanism at the entry end of the machine once it gets to the desired length. Typically pre-cut rollforming is used for in-plant machines, and the shear is situated in the infeed area of the machine. It cuts the material once it reaches the specified length before it reaches any of the forming stations.

Advantages of Pre-Cut Rollforming

Some advantages of using a pre-cut rollforming machine are that the cut is cleaner since material is cut before being formed. The ends of the material are clean, and there’s no distortion in the material since it’s a flat shape.

A pre-cut rollformer is typically easier to maintain since you have less wear and tear on the blade and cutting apparatus. It doesn’t require as much lubrication as a post-cut machine, and it’s easier to replace and maintain the shear blades.

With pre-cut rollforming, you don’t have entry and exit shear dies to maintain, replace, or change, which can be costly and take time. Shear dies in a post-cut rollforming machine are specific to each roller set and may require changing when switching to a new profile. They support the panel legs so that the shear cuts the legs instead of crushing them. Because the material is cut flat before it enters the rollforming machine, the profile you plan to produce doesn’t matter.

Disadvantages of Pre-Cut Rollforming

There are some instances where pre-cut rollforming may not be the best option.

With pre-cut rollforming machines, you often can’t run short pieces of panels like you can with a post-cut machine. As the material goes through the machine, it’s shaped by the forming stations and forming rollers. If it’s too short from the start, once you get to a certain point inside the machine, the material may not be engaged by a forming station and can shift inside the machine, coming out where the edges are clean but the panel is at an angle.

The minimum length of material you can run through the rollformer is typically the length of the machine itself. Pre-cut machines can be large with more forming stations which can increase the cost.

Another disadvantage of using pre-cut rollforming equipment is that the forming rollers inside the machine are the components that help drive the material through the machine. These components must be timed precisely and moving simultaneously so that the material can be pulled through the machine and formed simultaneously, avoiding oil canning or distortion of the material as it’s formed.

What Is a Post-Cut Rollforming Machine?

On a post-cut rollforming machine, the metal enters the machine, goes through the forming stations, and gets sheared after it comes out. Most portable rollforming machines are post-cut since they typically don’t require a big footprint.

Advantages of Post-Cut Rollforming

Unlike pre-cut rollforming, post-cut rollfoming is the preferred choice for most portable rollforming equipment. It utilizes a stationary cut, so the panel will likely come out square.

There’s no limit to the length of the panel you can produce. You can make and easily shear a panel that’s a few inches to 100 feet long, which is helpful when making profiles that don’t require a lot of material, like soffits.

Post-cut rollforming machines shear dies to protect the legs of the panel from getting damaged or deformed. The dies can also help eliminate any camber or bending of the panel as it exits the machine.

Another benefit to using post-cut machinery is that the panel coming through the machine is less likely to crash upon exiting the machine. The material in a post-cut rollforming machine is constantly fed into the machine and passes through the forming stations and drive rollers. This constant movement also increases production rates since the material is moving through the machine faster.

Disadvantages of Post-Cut Rollforming

With post-cut rollforming, however, you may not have as clean a cut with the shear as you would find in a pre-cut rollforming machine. The ends of the panel may have burrs or can even get distorted if the shear dies aren’t correctly aligned.

Regular maintenance on post-cut rollforming machines add time and costs. The shear blades and shear dies on a post-cut portable rollformer must be properly and continuously lubricated and cleaned to ensure the cut is clean.

While shear dies are beneficial for keeping the finished panel’s shape intact, they need to be switched whenever you run a new profile. It can take some time to get them changed and properly aligned to avoid material crashing into the dies.

Considerations to Make When Choosing Pre-Cut vs. Post-Cut Rollforming Machines

When you’re debating between a pre-cut or post-cut rollforming machine, it depends on whether you want an in-plant or portable machine and how you plan on using the equipment for your metal roofing operations. Talk to the machine manufacturer about their products and get an idea of why they designed it as pre-cut or post-cut and which would be best for you.

When considering which type of rollforming equipment to use, it can be helpful to think about the following:

- How much maintenance is required to keep the machine and shear functioning optimally?

- What time or labor is involved with operating or maintaining the machine?

- How short do you typically need to make panels?

- Do you want to use the machine at job sites or inside a plant?

- Are there limitations in your plant or shop for the size of rollforming machine you can get?

- How cleanly do you want your cut to be on the panel?

Final Thoughts

Deciding on a pre-cut or post-cut rollforming machine is up to you and how you’ll use it, but understanding what makes these two different from each other, their uses for metal roofing, and some of the pros and cons can help you in your decision-making.

New Tech Machinery’s portable rollforming machines are post-cut. Still, we understand that being an informed customer is knowing what options are available to you and what will ultimately fit your business needs. To talk about the differences between in-plant and portable rollforming machinery, what may be suitable for your metal roofing business, or learn more about NTM machines, talk to one of our rollforming specialists.