Mechanical Lock vs. Snap-lock Metal Roof Profiles: What Are the Differences?

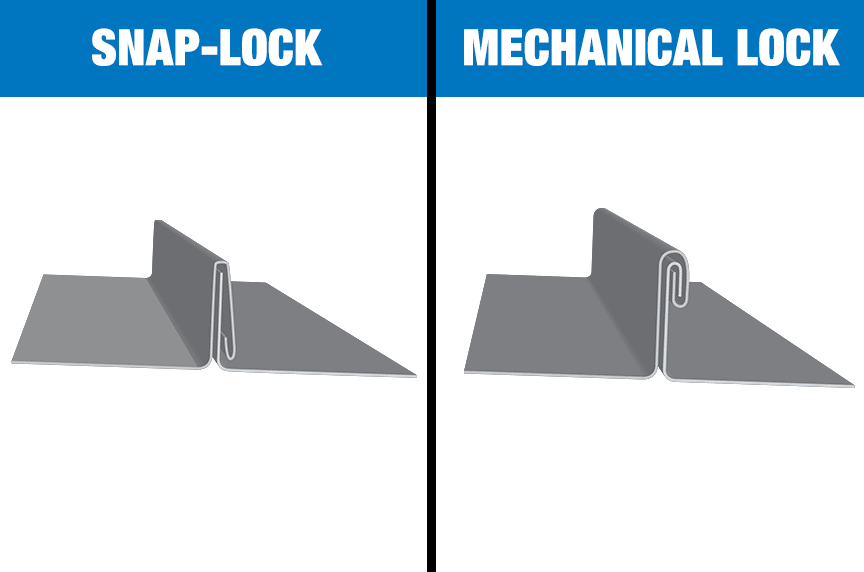

If you’re just making inroads into metal roofing, you may already be familiar with standing seam metal roof profiles. There are actually two variations: Mechanical seam and snap-lock metal roof profiles. While you can apply either to a residential or commercial project, you’ll find differences between them.

In this article, we’ll walk you through the differences between mechanical seam and snap-lock metal roof profiles, including the pros and cons of each. Additionally, we’ll show you a single profile that can be mechanically seamed or snap locked — only available through New Tech Machinery (NTM).

Understanding the characteristics, advantages, and disadvantages of these types of panel profiles can help you decide what profile is the best option to use on your next metal roofing project.

Table of Contents:

- What Is a Mechanical Lock Panel Profile?

- What Is a Snap-Lock Panel Profile?

- FAQs

- Which Profile Can Be Mechanically Seamed or Snap-Locked

- Mechanical Seam vs. Snap-Lock: Which Is the Right Choice?

What Is a Mechanical Seam Panel Profile?

Mechanically seamed metal roofs have vertical legs that line up with each other and are seamed together using a hand or power seamer. Using a power seamer on mechanical seam provides a tighter, sturdier seam than hand-seaming. Plus, it will save you a lot of time and effort.

The concealed clips are an essential part of the mechanical seam system. Often, mechanical seam profiles require expansion clips to account for the panel’s thermal movement, so it’s important to talk to your coil supplier about which clip is right for your mechanical seam profile.

What Are the Two Types of Mechanical Seam Profiles?

The two types of mechanical seam profiles used on standing seam metal roofs are:

- Single lock

- Double lock.

A single lock seam refers to the single fold of the seam (90-degrees). Benefits of using a single lock profile include less installation labor and easier replacement of damaged, as compared to the double-lock.

Double lock seams have been folded over twice (or 180 degrees). They’re most ideal for low-slope buildings for extra weather-tightness. While they’re stronger than any other standing seam metal roof profile, they are more labor-intensive to install and replace, which increases the price for your customer.

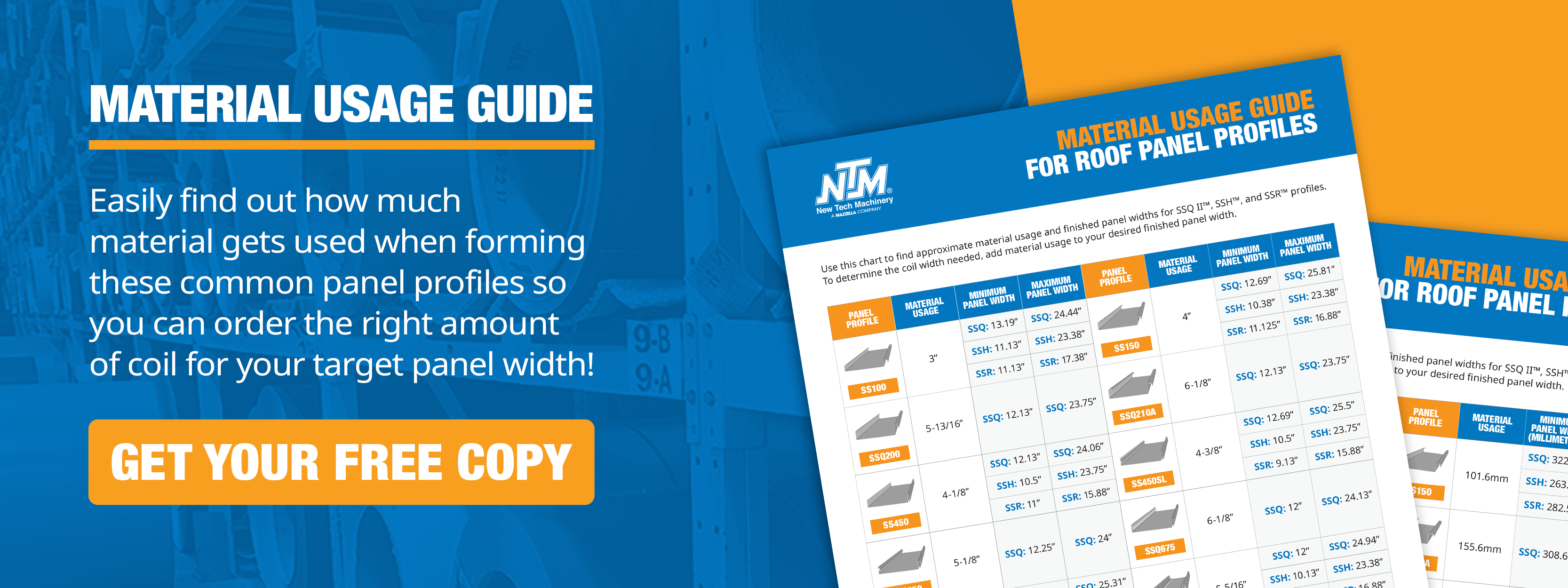

Mechanical lock profiles available with New Tech Machinery’s SSH™ MultiPro, SSR™ MultiPro Jr., SSQ II™ MultiPro, and SSQ3™ MultiPro Roof Panel Machines include the following (Not all machines can produce every profile):

- SS100 (1″ mechanical seam profile)

- SS150 (1.5″ mechanical seam profile)

- SSQ200 (2″ mechanical seam profile)

- SSQ210A (2″ ARMCO style mechanical seam profile)

Advantages of Using Mechanical Lock Profiles

- Strong and durable: Mechanical seaming increases panel rigidity for better resistance to high winds and severe weather.

- Suitable for low-slope roofs: Mechanical seam panels can be used on roofs down to 2/12 pitch (and sometimes lower), subject to project specs and panel limits. Sealant is typically required below 2/12. Always confirm minimum pitch with the manufacturer.

- Variable seam heights: Field-seamed profiles are available in 1″, 1.5″, and 2″ seam heights.

- Improved watertight performance: Mechanical lock seams are ideal for low-slope conditions where water lingers. The seaming process tightens joints to limit water entry; adding sealant to the panel legs further improves waterproofing.

Disadvantages of Using Mechanical Lock Profiles

- Unseaming concerns: Removing panels can crack the legs or the panel when unseaming and re-seaming. Proceed carefully and follow manufacturer guidance.

- More labor and cost: Mechanical lock systems require a hand crimper or electric seamer, adding install time and expense. If buying a seamer isn’t in the budget, consider renting to avoid upfront cost.

- Seaming risks: If the seamer jumps, is misused, or out of adjustment, it can damage seams and panels—costly callbacks. Whether you prefer hand or electric, proper setup and technique are critical.

- Clip telegraphing: Panel clips can “print” through the seams, revealing clip locations.

What Is a Snap-lock Panel Profile?

Snap-lock panel profiles are easier to install than mechanical seam as they have male and female legs that snap together, just as the name suggests. Unlike mechanical seam profiles, with snap lock, you don’t need a seamer or hand tool. Snap-lock requires less labor and allows for faster, easier installation.

This profile is typically used on a roof slope of 3:12 and greater unless otherwise specified by the manufacturer. Snap-lock profiles are widely used on both commercial and residential buildings.

Snap-lock profiles use fasteners or clips to attach the metal panel to the roof deck. Although you don’t need a seamer, the whole panel seam must be securely snapped into place.

When forming snap-lock profiles with a portable rollforming machine, typically it takes more material because of the complexity of the panel legs and the bends required to ensure this panel profile snaps into place securely.

Snap-lock profiles you can make with New Tech Machinery’s SSH MultiPro, SSR MultiPro Jr., or the SSQ II MultiPro Roof Panel Machines include the following (however, not every profile will be available with each machine):

- SS450 (1.5″ Snap-lock profile)

- SS450SL (1.5″ Snap-lock profile)

- SSQ550 (1.5″ Snap-lock profile)

- SSQ675 (1.75″ Snap-lock profile)

Advantages of Using Snap-lock Profiles

- No seaming tools necessary – This profile style has a male and female leg that just gets snapped together, so you don’t need any seaming tools to connect the panels.

- Typically easier and faster to install – Since snap-lock profiles don’t require any mechanical seaming, this system typically requires less labor to install and is generally cheaper.

Disadvantages of Using Snap-lock Profiles

- Steep-slope only: Snap-lock profiles are intended for roofs 3/12 and steeper. They’re designed to shed water, not hold it. Adding sealant in the panel legs can improve waterproofing but doesn’t change the slope limitation.

- Must snap securely: Ensure seams are tightly snapped and fully engaged for best weather resistance and to prevent disengagement over time.

Which Metal Roof Profile Can be Mechanically Seamed or Snap-Locked?

New Tech Machinery’s proprietary SSQ275 NewLock 2″ profile can be mechanically seamed or snap-locked, which is a money and time-saving advantage if you’re running both types. If you own a portable rollformer, you’ll need to purchase separate profiles for each. However, with NTM’s SSQ275 metal roof panel profile, you can have both in a single profile. The SSQ275 can only run through NTM’s SSQ, SSQ II, and SSQ3 MultiPro Roof & Wall Panel machines.

The SSQ275 is a 2″ standing seam panel with strength shown to meet or exceed that of existing profiles. Optional ASTM and UL testing and an Installation & Detail Manual are available through our partner Karr’s Building Supply (contact NTM for more information).

The SSQ275 NewLock proprietary panel system:

- Can be snap-locked or mechanically seamed

- Fits in SSQ and SSQ II Roof Panel Machines

- Snap-lock design provides added seam strength

- 2″ tall finished panel

- Easier installation

- When seamed in a single-lock configuration, this interlocking panel profile system is as strong as or stronger than many of the industry’s double-lock systems.

- Optional testing and Install/Detail Manual available for SSQ275 panel profile through Karr’s Building Supply – contact NTM for more information.

Mechanically Seamed vs. Snap-lock Profiles: Which Is the Right Choice?

What’s the roof slope?

Knowing whether the roof is a steep or low slope will help determine which is the right profile for the job.

As we said before, mechanical lock profiles work best on low slopes since they’re more water and wind-resistant, making them a popular choice in mountain and storm regions. Mechanical seam, with its thin ribs, give roofs a sleek look that some homeowners prefer.

Snap-lock is the more cost-effective option and is plenty sufficient in most situations.

How labor-intensive and costly is the profile to use in metal roofing installation?

Snap-lock panels install faster—fasten to the deck with clips or screws, then snap the seams. Mechanical lock panels require a hand or electric seamer to fold the legs, which adds time and typically increases cost.

What is the weather and temperature like in the area?

Lastly, you need to think about what the weather is typically like in the region you’ll be working on the metal roof. If the area gets a lot of harsh weather, high winds, or cold and freezing temperatures, a mechanical lock profile is probably your best bet.

Final Thoughts

The best place to begin is to know your market. What’s popular in your region, or the area you’re serving?

Now you should better understand the differences between mechanical seam and snap-lock, along with the different characteristics of each and pros and cons. Also, refer to the manufacturer for their recommendations.

With over 30 years of manufacturing portable roofing rollformers and equipment, New Tech Machinery knows how important it is to be an educated customer. We strive to provide our customers with educational and informative resources that can help them feel more confident.

If you have additional questions regarding standing seam panel profiles, or which profiles are available with NTM portable roof panel machines, contact us.