What is NTM’s New Z-Cutter Metal Z-Closure Flashing Shear?

As a metal roofing contractor, you know Z-closures are the best solution for ridge caps, unlike other ill-advised trim details. Manually measuring and cutting Z-closures is time-consuming and labor-intensive, costing you money. New Tech Machinery (NTM) has developed a tool to streamline this task—the Z-cutter metal Z-closure flashing shear, or just the Z-cutter, for short.

Let’s dive into the features and benefits of this new tool and see how it can drive up project efficiency.

What Is the Z-Cutter?

The Z-cutter is a specialized device designed to precisely and consistently cut pre-formed Z-closures, essential for locking ridge caps onto metal roofs. These closures need to be accurately sized to match specific panel widths.

Key Features of the Z-Cutter

1. Simple Assembly and Operation

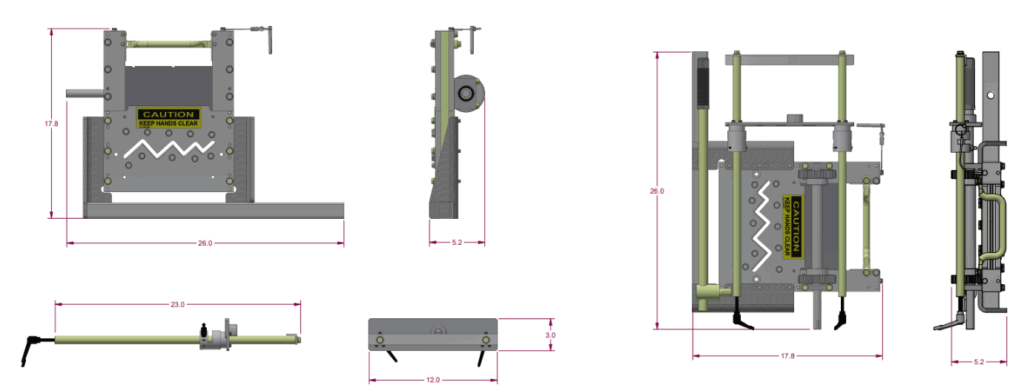

The Z-cutter comes in three main components:

- A main body that attaches easily to your SSH™ MultiPro, SSR™ MultiPro Jr., or SSQ™ MultiPro rollformer’s lower run-out stand hanger.

- A quick-adjust backstop with spring-loaded knobs for precise length adjustments.

- A detachable handle that provides effortless operation and cycling of the shear mechanism.

Assembly is straightforward, typically requiring only a 3/16″ Allen wrench for handle installation. Quick-adjust knobs allow you to set the cutting length accurately and quickly, while their unique spring-loaded design ensures they never obstruct the operator’s workspace.

2. Precision Cutting and Consistency

One of the biggest advantages of the Z-cutter is its ability to consistently deliver straight, square cuts every time. The built-in backstop and specially designed lip guide the Z-closures into position, ensuring precise alignment. This prevents the Z-closures from twisting or deflecting during the cutting process, producing consistently accurate results.

3. Versatile and Job-Site Friendly

While the Z-cutter is primarily intended for standard-length Z-closures (1”, 1.5” and 2” in height), it can also handle occasional specialty cuts, such as longer closures for steep hip angles, without sacrificing accuracy. Its compact, robust design makes it easy to integrate into existing setups and transport between job sites.

4. Ergonomic and Efficient

The Z-cutter is designed with ergonomic considerations, ensuring user comfort and safety. A built-in handle allows for easy lifting and placement. However, it’s important to note that the cutter isn’t designed to be transported with Z-closures or accessories attached to prevent accidental damage to components.

Benefits of Using the Z-Cutter

Significant Time Savings

Cutting Z-closures traditionally involves marking each piece individually, cutting manually with snips, or using abrasive tools and saws. This can take hours and prolong your roofing project. The Z-cutter enables contractors to complete the same task in a fraction of the usual time.

Reduced Labor Costs

Manual cutting demands meticulous measurement, increasing labor costs. The Z-cutter simplifies the process, allowing fewer workers to produce better, more consistent results, saving thousands in labor expenses over the life of your projects.

Maintains Manufacturer Warranties

Unlike abrasive cutting methods, which can void warranties on painted finishes due to heat and friction, the Z-cutter delivers clean cuts without compromising material integrity. This preserves the manufacturer’s warranty, providing peace of mind to contractors and homeowners alike.

Optimizes Material Usage

The Z-cutter complements common metal-folding machinery (such as standard 10-foot brakes), allowing contractors to efficiently utilize leftover trim pieces to create Z-closures, reducing waste and maximizing material efficiency.

The Z-cutter can cut 26-gauge and 24-gauge steel, and .032 and .040 aluminum.

Last Take on the Z-Cutter

The Z-cutter by New Tech Machinery is designed specifically with contractors’ needs in mind—saving you time, reducing labor costs, and consistently producing high-quality Z-closures. By streamlining the cutting process, this accessory empowers you to deliver faster, more reliable results, enhancing your overall productivity and profitability.

The Z-cutter is priced at $3,700

For more information about the Z-cutter, or any NTM portable rollforming machine or accessory, contact us.