Portable Roof Panel Machines: New Tech Machinery SSQ II vs. SSR

Updated for 2025

Looking at portable roof panel machines? Two of New Tech Machinery’s (NTM) popular models to compare are the SSQ II™ MultiPro Roof and Wall Panel Machine vs. SSR™ MultiPro Jr. Roof Panel Machine. While they are on opposite ends of the spectrum–the SSQ, our flagship and most advanced model vs. the SSR, our starter panel machine–as a metal roofing contractor or panel manufacturer, there’s a lot that goes into choosing and purchasing the right portable roof panel machine.

You may think you need our SSQ model given its high versatility and functionality, but that all depends on your goals. If you’re looking for just a couple of standing seam profile options for the occasional job, having an SSQ II might be a little like flying a rocket ship to the grocery store when a Toyota will do, and may be a lot easier to park.

That said, there’s absolutely nothing wrong with a rocket ship for big or high-volume jobs. And there’s nothing wrong with an SSR MultiPro Jr. if you’re doing some residential or light commercial work. So, here’s a head-to-head comparison of NTM’s SSQ II and SSR portable roof panel rollforming machines to help you make the right decision based on your operation and business goals.

In this article, we’ll talk about how these two machines compare in the following areas:

- Standard features of each machine

- Machine specifications and what materials you can run

- Cost of each machine and factors affecting it

- Add-ons and accessories available with each roof panel machine

- Which profiles each machine can produce

- Whether the machine is designed for residential vs. commercial projects

Notable Standard Features

Both the SSQ II and SSR machines come with many of the same standard features, but a few distinguish one machine from the other. Below we compare the standard features of the SSQ II machine with those of the SSR.

SSQ II MultiPro Roof and Wall Panel Machine

- Roller System with Shear Dies

- Hydraulic Drive & Shear

- Power Interruption Safety Circuit

- UNIQ® Control System – Manual controller (standard), Batch-and-length controller (optional), or Automatic controller (optional)

- Choice of: Quick-Change™ Profile Roller System

- Choice of: Quick-Change™ Power-Pack – gas or electric power (220V or greater )

- Choice of one pair of minor rib rollers – Bead Ribs (regular or wide), V Ribs (large or small), Pencil Ribs (large or small), or Striation Ribs

SSR MultiPro Jr. Roof Panel Machine

- Length Control Limit Switch

- 100-Foot, 10 Gauge, 20 Amp Extension Cord

- (2) Run-Out Tables (10-Foot Sections Each)

- Forward Pulling, Easy Cut Manual Shear

- Dual Overhead Reel Rack

- One Expandable Arbor / Reel

- Choice of: EZE-Change™ Profile Roller System with Shear Dies

- Choice of one pair of minor rib rollers – Bead Ribs (regular or wide), V Ribs (large or small), Pencil Ribs (large or small), or Striation Ribs

Conclusion

While this is not a complete list of all the standard features of each portable roof panel machine, these are unique to the SSQ II and the SSR. Features to keep in mind: The SSR runs only on electricity, so you’d need a power source to take it on the road; whereas the SSQ II can run on an electric motor or gas engine.

Also, the SSR uses a manual shear, where the SSQ has a hydraulic shear and drive. We’ve seen contractors build their businesses using the SSR for residential and light commercial work, but someone has to pull that shear lever. Because of its automation, the SSQ also has more safety features, like the shear guard and power interruption safety circuit.

Machine Specifications

SSQ II MultiPro Roof and Wall Panel Machine

Machine Dimensions

- Length: 14’ 4” (4.4m) without angled slitter, 15’ 4” (4.7m) with angled slitter

- Width: 5′ 2″ (1.57m)

- Height with overhead rack: 43 5” (1.3m)

- Height without overhead rack: 2’ 6″ (0.8m)

- Weight of machine (with roller set, power pack, and rib rollers) 2,830 lbs. (1,280kg)

Machine Dimensions on Trailer

- Length: 18’ 11” (5.8m)

- Width: 7’ 2 1/2”(2.2m)

- Height with reel: 6’ 3” (1.9m)

- Weight: 5,090 lbs. (2,300kg)

Machine Speed

- Up to 75 ft./minute (23m/min) with gas power (approximately 51 ft./minute when using electric power)

SSR MultiPro Jr. Roof Panel Machine

Machine Dimensions

- Length: 12’ 6” (3.9m)

- Width: 3’ 10” (1.2m)

- Height with Over Head Rack: 4’ 3” (1.3m)

- Height without Over Head Rack: 1’ 10” (.6m)

- Weight: 1,715 lbs. (780kg)

Machine Dimensions on Trailer

- Length: 18′ 11″ (5.8m)

- Width: 7’ 2-1/2″ (2.2m)

- Height with Reel: 6’ 3” (1.9m)

- Weight: 3,975 lbs. (1,800kg)

Machine Speed

- 30 ft./min (9m/min) approximately with gas power

Conclusion

The SSQ II is a bigger machine overall and has more speed. If you’re running big jobs or high volume, the SSQ is a workhorse. If you’re looking for a more compact machine to run panels for a smaller projects or at low volume, the SSR is a great option.

Materials Formed

SSQ II MultiPro Roof and Wall Panel Machine

Coil width: 15” to 30” (381mm to 762mm)

Finished panel width: 12” to 24” (305mm to 610mm) – Depending on the panel profile

- Steel: 28 ga. to 22 ga. (0.4mm to 0.8mm) (painted, Galvalume, coated galvanized)

- 50 ksi maximum for 24 to 22 ga.

- 50 ksi recommended, 80 ksi acceptable with adjustments for 28 ga. to 26 ga.

- Painted Aluminum: .027” to .040” (0.7mm to 1.0mm)

- Copper: 16 oz. to 20 oz. 3/4 Hard (0.5mm to 0.7mm)

- Terne Coat Stainless: 26 ga. (0.5mm)

SSR MultiPro Jr. Roof Panel Machine

Coil width: 15” to 20” (380mm to 508mm)

Finished panel width: 10” to 16” (254mm to 406mm) – Note: Variable Depending on Panel Profile

- Painted Steel: 28 ga. to 24 ga. (0.4mm to 0.6mm) (painted, Galvalume, coated galvanized)

- 50 ksi maximum for 24 ga.

- 50 ksi recommended, 80 ksi acceptable with adjustments for 28 ga. to 26 ga.

- Painted Aluminum: .027” to .040” (.7mm to 1.0mm)

- Copper: 16 oz. to 20 oz. 3/4 Hard (.5mm to .7mm)

Conclusion

Both machines are similar in terms of what materials you can use with your portable roof panel machine. If you’re looking to run a wider coil (depending on the profile), the SSQ II machine can run a 15” to 30” coil and get you a finished panel width of 12” to 24”. The SSR can run up to a 16″ wide finished panel.

The other big difference is the SSQ II can run up to 22 ga. steel, which is typically specified for commercial projects. The SSQ II has greater drive power than the SSR, which lends to its versatility for commercial and residential roofing projects.

Price

SSQ II MultiPro Roof Panel Machine

The starting price of the SSQ II is $63,000 USD without a panel profile. This base price does not include any additional features or accessories offered at the time of purchase other than what is listed above in notable standard features. So for a complete setup with a profile and accessories, you’re looking at spending $120k to $130k.

There are also in-plant and portable packages available for the SSQ II machine. Package pricing for an in-plant machine starts at $68,000 USD, and pricing for a portable machine package begins at $68,500 USD (starting packages include limited SSQ II profile options).

SSR MultiPro Jr. Roof Panel Machine

The base price of this machine is $41,200 USD and includes on profile, but does not include any accessories or add-on options offered at the time of purchase other than what is listed above in notable standard features.

Conclusion

Factors that influence both machine’s price and cost include:

- Versatility – The SSQ II offers 16 different wall and roof panel profiles and can be used for both commercial and residential projects, making it a more versatile machine for contractors and manufacturers. The SSR, however, only produces seven profiles.

- Hydraulics – The SSQ II has hydraulic drives and shear, increasing its speed and automating the shear. The SSR is an electric drive machine with a manual shear, making it lower in price but also limiting the speed and drive power.

- Electronic computer controller – The SSQ II is available with our most sophisticated, safest, and reliable computer controller yet, the UNIQ® Control System. The UNIQ Control System is not yet available on the SSR machine; however, the SSR machine has an optional EZC EZ Counter digital length controller that allows operators to run panels to specific lengths.

- Drive system – The number of drive rollers inside a portable roof panel machine and the type of drive rollers used, helps determine the thickness and gauge of material that can be run through the machine and also affects machine pricing. On the SSQ II, there are 16 hydraulically-driven rollers via chain, sprocket, and gear. On the SSR, the eight drive rollers are driven electrically via chain and sprocket.

Select Add-On Options and Accessories

SSQ II MultiPro Roof and Wall Panel Machine

Some add-on options and features are exclusively available with the SSQ II machine that can improve your productivity on projects. They include:

- Notching Capabilities – This accessory punches the notches before the legs are formed for a clean and precise cut and is available in rectangular or profiled notching.

- Angle Slitter – The angle slitter cuts notched panels up to 24” wide at any angle from 90° to 35° after they’re formed for a precise and faster cut. This feature is only available with the Notching System.

- UNIQ Control System – This latest enhancement to the SSQ II machine is more than a batch and length controller, it is global (CE) compliant, has improved end-user troubleshooting capabilities and touchscreen, and increased safety features.

- Hot Melt Sealant Pump Interface – This wiring system works in conjunction with the machine’s computer controller to put mastic or sealant into the legs of the finished panel as it comes out of the machine.

- Quick-Change Power Pack – This device quickly field-converts the machine’s power source from gas engine to an electric motor and from an electric motor to a gas engine, as needed.

- Dual Overhead Reel Rack and Expandable Reels

- 10’ Sections of Run-Out Tables

SSR MultiPro Jr. Roof Panel Machine

Exclusively available with the SSR machine is the EZ-Counter Computerized Length Controller. This add-on option allows you to program up to 50 different lengths to automatically run the panel’s correct length. Because this is not a batch controller, it will only run one length at a time. It can track material and provides more accurate measurements than measuring by hand or using the limit switch.

Conclusion

While portable roof panel machine add-on options and accessories are not necessary for machine use, they allow for easier and more efficient operation of the machine and can reduce the number of people needed to operate the equipment.

If you’re looking for a portable roof panel machine with versatility in add-on options, the SSQ II is an option for anyone looking for a machine that will grow with your business. If you just want a simple machine without many of the “bells and whistles” for a more budget-minded price, then the SSR is an excellent option.

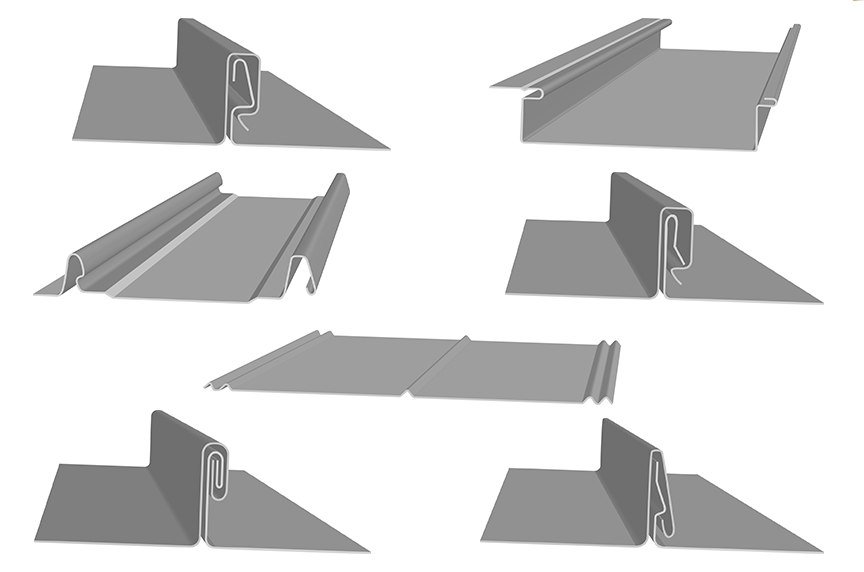

Metal Roof Panel Profiles

SSQ II MultiPro Roof and Wall Panel Machine

The SSQ II can produce over 16 different residential and commercial profiles in various styles, including snap-lock, mechanical seam, fastener flange, flush wall and soffit, trapezoidal, t-panel, board and batten, and a proprietary panel that can be both snap-locked or mechanically seamed.

SSR MultiPro Jr. Roof Panel Machine

Although the SSR can only produce seven metal roof panel profiles, it can still form different styles popular in residential or light commercial building applications. The SSR can produce snap-lock, mechanical seam, fastener flange, and t-panel profiles.

Conclusion

Each business operation will be different depending on how many profiles and the styles you want to offer to customers and utilize in your business.

If you’re looking at keeping with the basic residential type panel profile and don’t see a need to provide commercial panels, the SSR may be the way to go. If you want to increase your current offerings, or possibly expand your business in the future and have that option to offer even more profiles, the SSQ II can produce panel profiles for all styles of commercial and residential building projects.

Residential vs. Commercial Projects

SSQ II MultiPro Roof and Wall Panel Machine

The SSQ II is an excellent option for both commercial and residential metal construction projects. It’s the perfect option for contractors looking to expand their businesses or for manufacturers hoping to use their machine to its full capabilities and produce a wide range of profiles. This machine’s Quick-Change™ Profile Roller System also allows you changeover profiles in 45 minutes or less with minimal tools needed for quicker turnaround on projects.

SSR MultiPro Jr. Roof Panel Machine

The SSR is a great entry-level machine for residential or light commercial projects. It’s perfect for smaller projects or a start-up/one-person metal roofing business. If you want to eventually expand your business and start implementing chop and drop services, this machine may not be the best fit.

Conclusion

When considering which portable roof panel machine is best for your residential, commercial, or light commercial projects you need to consider more than just which machines can handle which type of building application.

You should also consider whether or not you want to expand your business operations or if you want to get into large commercial projects in the future. Either way, both machines are viable solutions for residential and commercial applications, depending on your business needs.

What to Consider Before Purchasing SSQ II vs. SSR Roof Panel Machines

Ask yourself these questions to help you decide whether you should purchase the SSQ II or SSR roof panel machines:

- How much do you need in your machine?

- What type of building projects do you do?

- What’s your budget like for portable rollforming equipment?

- How many profiles do you want to offer customers or that you plan on using for your projects?

- How do you plan on using the machine? Is this just for your current operation, or do you plan to expand into offering additional services?

- Where is your business now and how much do you want to grow or expand in the future?

Final Thoughts

If you’re deciding between New Tech Machinery’s SSQ II or SSR portable roof panel rollforming machine, the good news is that both machines are great options depending on your business. They both have various add-on options to help leverage your use of the machine, can form multiple styles of profiles, and are easy to use no matter your experience with this type of equipment.

With over 30 years of manufacturing the world’s finest portable rollforming equipment, New Tech Machinery understands it’s not always easy to make this kind of decision on your own. Whether you’re leaning towards purchasing a new NTM rollformer, or looking for a machine to fit your current business needs, we’re here to help make sure you feel confident and prepared in choosing the right portable roof panel machine.

To learn more about the SSQ II or SSR roof panel machines, or any of our portable rollforming equipment, contact us today to speak with one of our experienced rollforming specialists.