NTM’s SSQ3™ MultiPro Premiering at METALCON 2025

The SSQ3™ MultiPro is here—and it’s about to change how you think about portable rollforming.

Sounds like a sales pitch, right? But our engineers have been busy working on new features, making NTM’s top-selling machine safer, smarter, and more efficient than ever.

The SSQ3 builds on everything contractors loved about the proven SSQ II™—the reliability, the versatility to run 16 optional standing seam and wall panel profiles—but delivers what you’ve been asking for: better visibility, faster adjustments, simpler maintenance, and enhanced safety.

See it first at METALCON 2025 in Las Vegas, October 21–23.

The SSQ3 isn’t just an upgrade—it’s designed around what matters most to contractors and plant operators: Maximum efficiency without compromising the rugged build quality NTM is known for.

How the SSQ3 Benefits Your Metal Rollforming Operation:

Safer operation, clearer alerts

- Sealed drive gear covers add a second safety layer and block debris.

- RFID cover sensors call out exactly which cover is open on the controller.

- Shear warning strobe provides a bright, line-of-sight cue before and during cycles.

- Improved bottom guarding limits hand access; slug funnel controls scrap for cleaner, safer floors.

Faster, tool-free setups and changeovers

- Quick-change guide rods and rib roller frame use large, retained hand knobs—no tools, fewer loose parts.

- Hang‑in rib roller frame supports itself while you secure it, cutting strain and setup time.

- Notcher entry door (if equipped) offers tool‑free access for rapid fine‑tuning when changing coil widths.

Quicker, cleaner maintenance

- Remote zerk fittings bring hidden grease points to the outside—no cover removal, less mess.

- Sealed gear covers with inspection windows let you visually check gear condition fast.

Better visibility where it matters

- Eight high‑output, low‑amp LEDs brighten rib roller, perforator, shear, and frame zones.

- Lights are LOTO‑friendly—powered on the input side so you can illuminate the interior during lockout/tagout.

Reliability and uptime gains

- Contaminant shielding and easier lubrication extend gear, bearing, and lubricant life.

- Fewer missed maintenance steps, faster diagnostics, and cleaner housekeeping reduce downtime.

At NTM, we’re driven by innovation. Our team strives to produce the smartest, safest and most efficient machines on the market. The SSQ3 is another step forward as we continue to engineer the future of portable rollforming.

Terry mcguire, ntm vice president

Highlights of What’s New—and Why It Matters

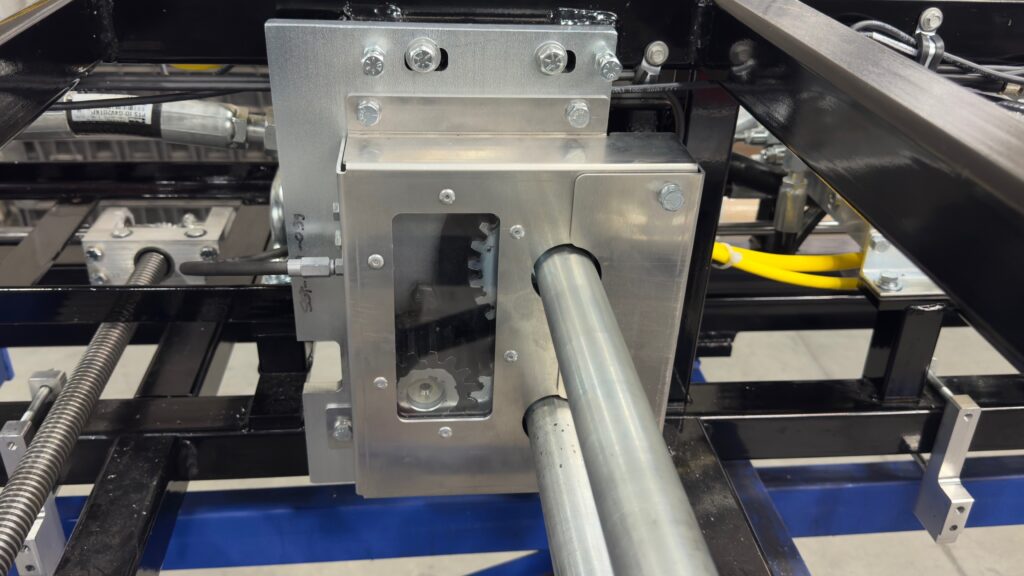

New: Sealed Drive Gear Covers with Inspection Windows

This one’s all about machine protection and safety. Imagine hauling your machine up a dirt road with dust trailing behind. You don’t want that dust getting up into the gears of your machine and causing friction.

So here’s what changed: The main drive gears are now fully guarded with dedicated covers that include inspection windows so you can see inside.

- Why it matters:

- Component protection: Shields gears from road grime, dust, and debris that can shorten gear life.

- Operator safety: A second layer of protection even when the main top covers are removed for service.

- Faster service: Look through the cover window and the machine window to assess gear condition.

New: Remote Zerk Fittings for Easy Lubrication

Maintenance matters. That’s why we have machines decades old still cranking out panels. It’s like the old saying, take care of your machine and it will take care of you. The zerk fittings help you keep the gears lubricated without having to bust out a wrench.

Now, key lubrication points (including behind the main drive gears and on the main drive shaft bearings) are accessible via remote zerk fittings—no cover removal required.

- Why it matters:

- Increased Efficiency: Quick greasing from the outside of the machine.

- Better reliability: Keeps contaminants out and extends lubricant life.

- Prevents hidden failures: “A majority of customers didn’t even know there were two bearings hidden behind those drive gears. Remote zerks and windows make maintenance easy.

- Benefit in practice: Less downtime, fewer missed maintenance steps, and longer component life.

Being able to see what’s going on without guessing is absolutely paramount for the operator.

Bryan yancy, Innovation & development engineer

New: Eight High-Output, Low-Amperage Interior LED Lights

Cover windows are great, but they won’t do you much good if you can’t see what’s inside. The SSQ3 adds eight strategically placed LEDs—two at the rib roller transition area (rib rollers/perforator/shear) and six along the frame—with an exterior-mounted light switch. These lights can operate even when the machine is off.

- Why it matters:

- Clarity when it counts: Setups, tool changes, and checks are easier—even in well-lit shops or bright outdoor conditions.

- LOTO-friendly lighting: Lights are powered on the input side of the power supply. With the machine locked/tagged out, you can still illuminate the interior.

- Enhanced notcher visibility: If equipped with notchers, lighting improves sightlines to the notcher area.

New: RFID Cover Sensors and On-Controller Diagnostics

It used to be that when a cover got knocked out of place, you’d have to look inside the machine and try to figure out which one was offset. No longer. RFID sensors now identify exactly which cover needs attention and displays it on the controller.

- Why it matters:

- No more crawling underneath to find a red/green indicator light.

- Saves time and helps ensure covers are correctly secured.

New: Notcher Entry Door with Tool-Free Access (If equipped)

For machines equipped with notchers, a new entry door uses two latches for fast access to adjust notcher cartridges—without removing end covers or grabbing tools.

- Why it matters:

- Rapid fine-tuning: Quick adjustments for hem/leg when switching coil widths (e.g., 20″ to 20-1/8″) without teardown.

- Integrated safety: The door retains an RFID interlock so the machine prompts you to close it before operation.

New: Shear Warning Strobe on the Controller

Nothing stops production faster than a jobsite injury, especially when it comes to the shear. Now, a high-visibility strobe mounted atop the controller warns when the shear is about to cycle and when it’s in motion.

- Why it matters:

- Clear, line-of-sight warning even in bright conditions.

- Reinforces safe hand placement and awareness around guarded shear operations.

New: Quick-Change Guide Rods with On-Machine Storage

This feature will save you time and increase operational efficiency. Guide rods now use knobs for tool-free removal and reinstallation, with dedicated on-machine storage at the gold bars.

- Why it matters:

- Faster swaps between standard tooling.

- Fewer loose parts to misplace; less juggling hardware during changeovers.

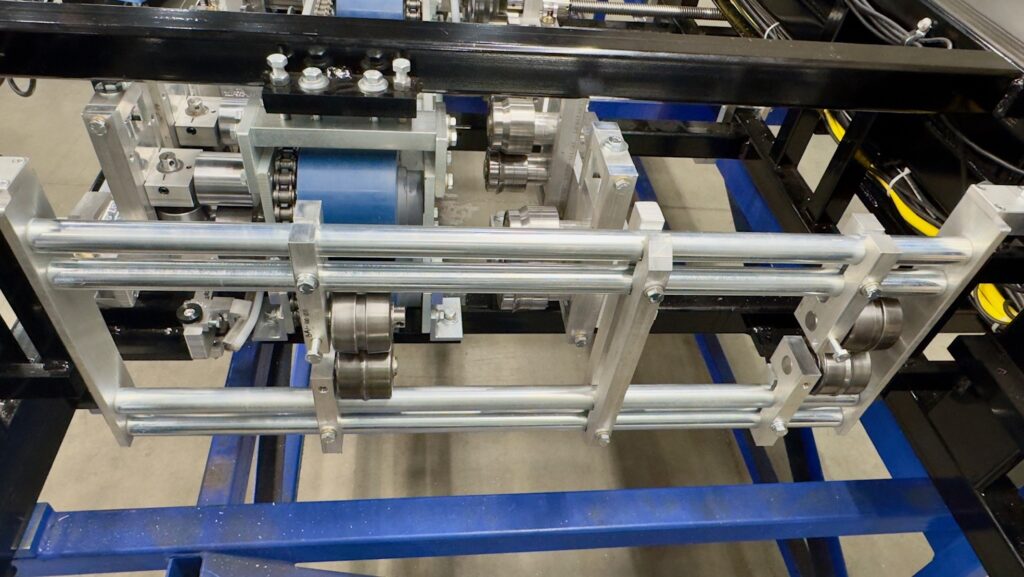

New: Quick-Change Rib Roller Frame with Hang-In Feature

Another timesaver. The rib roller frame is now quick to remove and comes equipped with a built-in hanging mechanism that supports the frame while you secure it.

- Why it matters:

- Speed and repeatability: Swap frames without wrestling hardware or redoing intricate roller adjustments.

- Operator-friendly design: Reduces strain and setup time compared to handling four bolts while supporting the frame weight.

- Competitive angle: No need to change individual rollers and redo all those adjustments every time. Swap the whole frame and keep your setup consistent.

Improved Bottom Guarding and Shear Slug Funnel

- What changed: Enhanced lower guarding prevents hand entry under the machine; a new funnel under the shear directs slugs to a single collection point.

- Why it matters:

- Safety first: Reduced pinch-point exposure beneath the machine.

- Cleaner jobsite: Slugs don’t ricochet around the trailer or shop—simpler housekeeping and faster cleanup.

Our machine is more solid than ever. These new items make it more user friendly and safer. The user understands what’s going on easier and can maintain the machine easier—often without taking the covers off.

Bryan yancy, innovation & development engineer

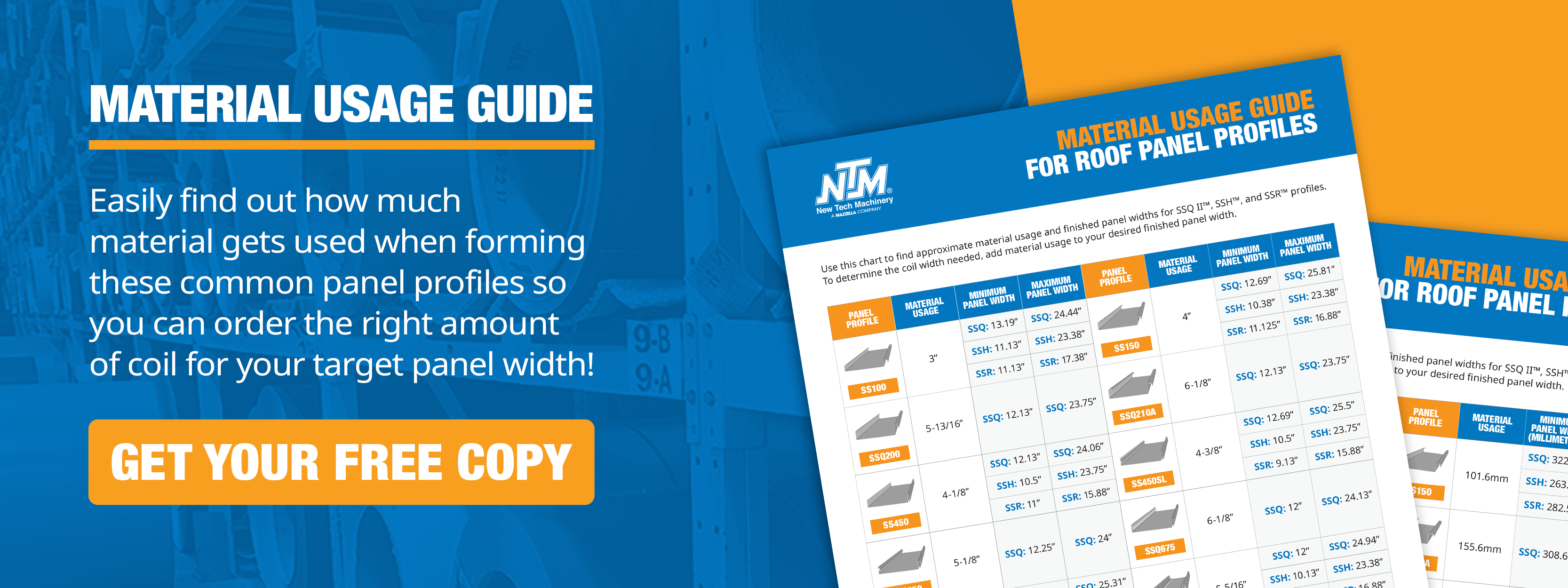

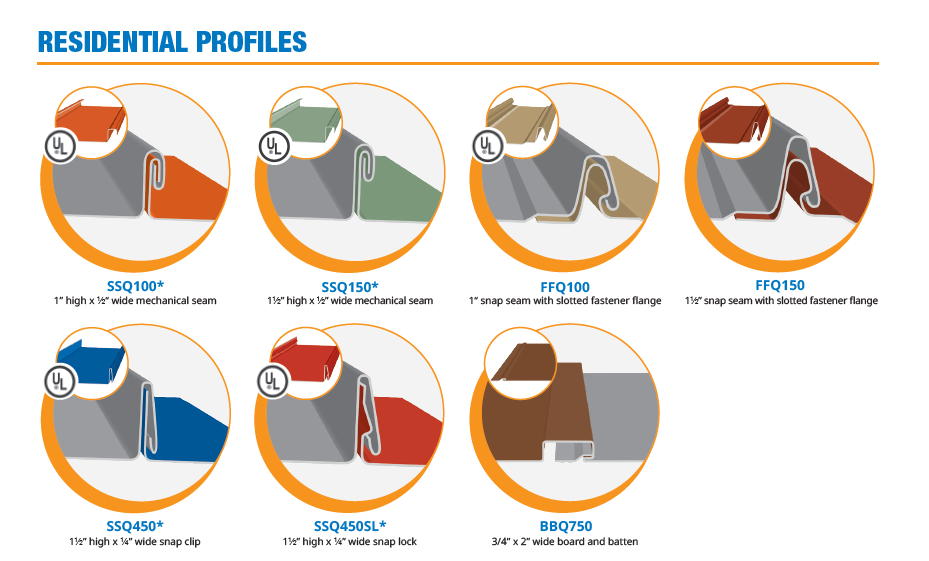

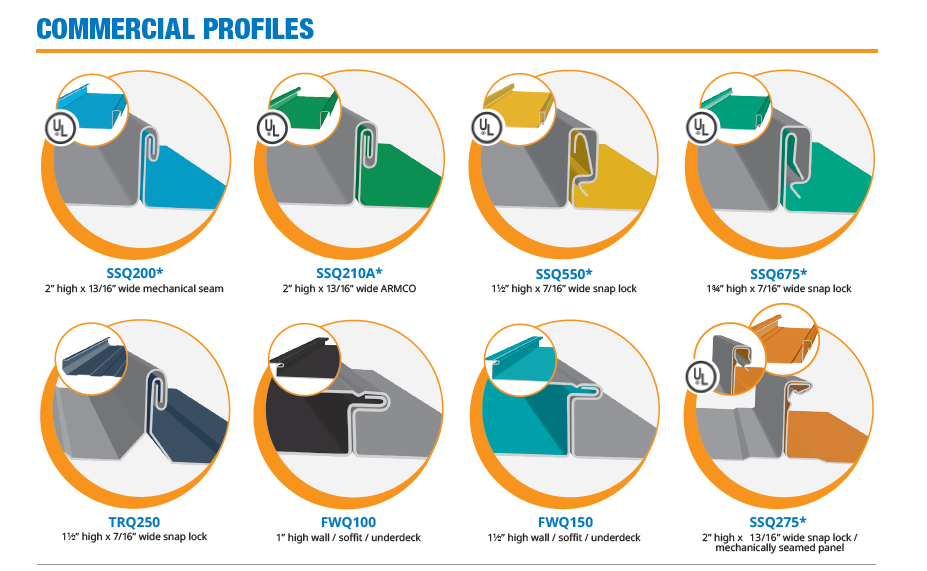

Profiles for SSQ3

The SSQ3 supports the proven SSQ roof and wall panel profile lineup.

- Mechanical seam

- SS100 – 1″ Mechanical Seam

- SS150 – 1.5″ Mechanical Seam

- SSQ200 – 2″ Mechanical Seam

- SSQ210A – 2″ ARMCO Mechanical Seam

- TRQ250 – 2.5″ Mechanical Seam Trapezoid

- Snap-lock

- SS450 – 1.5″ Snap-Lock

- SS450SL – 1.5″ Snap-Lock

- SSQ550 – 1.5″ Snap-Lock

- SSQ675 – 1.75″ Snap-Lock

- FF100 – 1″ Snap-Lock with Slotted Flange

- FF150 – 1.5″ Snap-Lock with Slotted Flange

- NTM’s Proprietary Dual Standing Seam Profile

- SSQ275—2″ Snap-Lock/ Mechanical Seam

- Wall/soffit/underdeck

- FWQ100 – 1″ Flush Wall/Soffit/Underdeck with Adjustable Reveal

- FWQ150 – 1.5″ Flush Wall/Soffit/Underdeck with Adjustable Reveal

- Board & Batten

- BB750 – Board & Batten

Note: Some profiles may require specific tooling sets, licensed details, or application-specific approvals. Always confirm profile availability and requirements with NTM before quoting.

Packages and Configurations

- Portable trailer package

- SSQ3 on NTM trailer, controller mount, coil payoff, runout tables, slug collection

- Built for jobsite production and fast setup/teardown

- In-plant package

- Fixed stand or integrated line with tailored material handling

- Optimized for throughput and repeatability

- Standalone machine (no trailer)

- For custom mounting, tight spaces, or unique shop layouts

Popular options and add-ons

- Notching (with new quick-access entry door and RFID interlock)

- Perforator

- Quick-change rib roller frame with hang-in feature

- UNIQ Automatic Control System

- Z-cutter z-closure fastener

- Roof Panel Machine Cart

- Free-Standing Decoiler

Why SSQ3 Over the Competition?

Even before these updates, SSQ’s reputation was built on durability, panel quality, and long-term reliability. “Our machine is more solid than everything that’s out there,” Bryan said. “These new items make it more user friendly and safer. The user understands what’s going on easier and can maintain the machine easier—often without taking the covers off.”

SSQ3 MultiPro Roof and Wall Panel Machine — FAQs

Who Shouldn’t Buy the SSQ3?

The SSQ3 is our top-of-the-line flagship portable metal roof and wall panel machine, capable of running 16 different profile options–more than any single portable rollformer on the market. There’s no beating it’s durability, reliability, or performance.

That said, not every operation needs the robust offerings of the SSQ3. If your operation only includes occasional metal roofing jobs or you’re doing residential to light commercial standing seam roofing, our SSH™ MultiPro or SSR™ MultiPro Jr. can produce seven optional standing seam profiles, enough for many contractors’ operational needs.

However, if you’re expanding into metal siding or taking on larger projects, the SSQ3 is well worth the investment and will leave you plenty of room for growth.

Bottom Line

Meet the SSQ3 MultiPro at METALCON 2025 in Las Vegas (Oct 21–23, Booth 4027).

The SSQ3 MultiPro brings cutting-edge innovation and technology even further in the portable rollforming industry. Stop by METALCON booth #4027 to see the SSQ3 MultiPro in action and talk with our service and sales team members about how an NTM portable roof panel or seamless gutter machine might be right for your operation.

Also, find out about our new configurator, and how we’ve simplified financing right on our website!

If you’re not sure which machine is right for your operation, take our panel machine quiz and find the portable rollformer that fits your needs.

For information about the SSQ3 MultiPro, or any of our portable roof panel or seamless gutter machines and accessories, contact us.