New Tech Machinery Machinists: Who Are They & What Do They Do?

We’re going to take a break from our regular educational articles about rollforming equipment to highlight one of the most important parts of New Tech Machinery (NTM): The people.

When You Think of a Machinist, What Comes to Mind?

Definition of machinist (noun):

A worker who fabricates, assembles, or repairs machinery; a craftsman skilled in the use of machine tools; one who operates a machine.

“Machinist” tends to be a general term for someone who works with machines to make products or to create the pieces and parts used to manufacture products. However, every machinist has a different background story of how they came to be in their current job and the experiences they’ve had in their position.

So, without further ado, we’d like to introduce Shawn Bennington (pictured above), a machinist who works in the shop at the New Tech Machinery headquarters in Aurora, Colorado.

Shawn came to us a month or two ago with a story of his own about a chance encounter he had with one of our customers, which led to a discussion about his role as a machinist. Not only did we get a better grasp on his everyday tasks, but we discovered what keeps Shawn at NTM and makes him an asset to our business.

What Does a New Tech Machinery Machinist Do?

Before we get into Shawn’s story, let’s talk about the daily tasks of a machinist in our world.

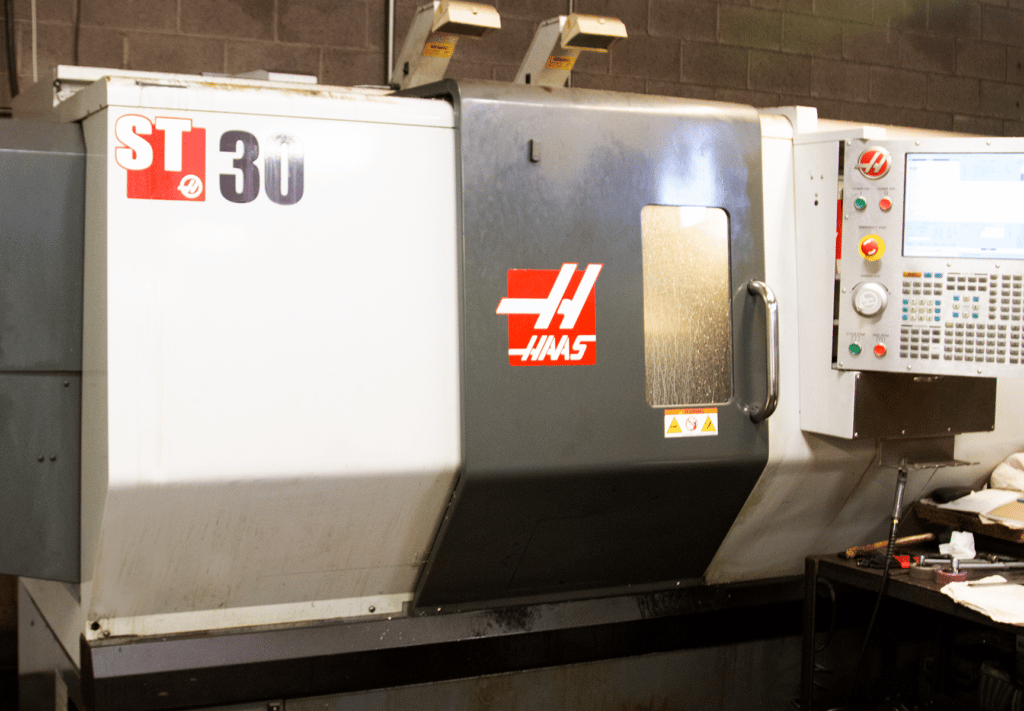

To put it simply, NTM machinists program on-site CNC machines to make the forming rollers (also called dies) and other miscellaneous metal pieces that are used on the inside of an NTM portable rollforming machine. There are different steps taken to create different parts, but the process typically goes as follows:

- The machinist receives the part prints/designs from the engineering department.

- The prints/designs are programmed into the CNC machine by the machinist.

- The correct tools used to manufacture the part are placed into the machine.

- The material making up the part (typically metal) is secured from the NTM saw department.

- The material is appropriately set into the machine.

- The machinist starts the CNC machine and runs the part.

- Once the machine has completed the cycle, a machinist will check the quality of the parts and ensure the dimensions are correct.

The machinists at New Tech Machinery go through around 10 to 15 different set-ups/prints each day for the parts they make. Each set-up/print produces anywhere from 10 to 100 pieces and is entirely dependent on need (some parts are standard, and some are unique).

Getting to Know Shawn

Shawn actually didn’t begin his career as a machinist; he started out working in a retail management job that he enjoyed, but quickly realized that the hours and the salary weren’t ideal. After looking elsewhere, an opportunity came up to work at a small “mom and pop” machining shop in Broomfield, Colorado, where he spent 18 years programming and working on older machines from the World War II era.

In August of 2011, Shawn decided that it was time for a change, which is how he was hired at New Tech Machinery as a machinist. Shawn says that the company switch was a little daunting because NTM was an “infinitely bigger business that came with a slight learning curve.” But Shawn caught on quick, and the rest is history.

After nearly 8 years working in the machine shop, Shawn attributes a lot of his motivation and personal success at NTM to Steve Levonyak, the Plant Manager at NTM Denver.

“Steve is a joy to work for. Not only is he a supportive manager to his employees, but he’s always focused on the quality of the products we are sending out to our customers,” Shawn said.

Shawn’s Personal New Tech Machinery Story

“Recently, I was heading home from work one late afternoon. I noticed a nondescript cargo truck on my street. I also noticed a seamless gutter machine inside the truck. On the side of the machine, I saw ‘New Tech Machinery’ emblazoned across it.

I stopped my car, got out of the vehicle, and walked over to a gentleman who was operating the machine. I said hi and asked him what he thought of the machine. Immediately, he smiled and stated that he ‘freaking loved it!’ He then proceeded to explain to me that it ‘just ran and ran and ran without any issues, ever.’ He, also, explained to me that it was the most reliable piece of equipment that he had ever had.

Of course, this caused me to smile. I then explained that I was a machinist for New Tech Machinery, and I was thrilled that he loved our product. He shook my hand and said thanks. We talked for a few minutes more about various things, then I told him goodbye and left.

It brings me great joy to approach someone I don’t know, ask them about our product, and receive such a wonderful review without even knowing who I am, or who I work for. It’s also an honor to work for a company where all we strive to do is deliver a high-quality machine that will produce superior quality products. From our CEO, Tony Mazzella, down to myself, Shawn Bennington, the machinist, we are all dedicated to producing a machine that just ‘runs and runs without any issues.’”

Final Thoughts

First, we want to thank Shawn for sharing his personal story and how he came to be a talented machinist at NTM.

Second, while the job of a “machinist” can vary quite a bit from company to company, it’s an essential role in the production process regardless. Not only do they have specific knowledge that most others don’t, such as programming and running a CNC machine, but they also make the parts that are vital to making our rollforming machines operational.

Here at New Tech Machinery, we put a lot of emphasis on hiring the most skilled and knowledgeable people, which in turn help us produce high-quality rollforming machines.