Rib Rollers for NTM Panel Machines: What You Need to Know

If you’re running a New Tech Machinery (NTM) portable roof panel machine—like the SSQ II, SSR, SSH, or even the 5VC Crimp—you’ve probably looked into adding rib rollers to your setup or chosen a set with your machine. They’re a smart way to combine function and style.

New Tech Machinery manufactures distinctive types of rib rollers to go with our profiles.

In this article, we’ll dig into what they are, the different types, their benefits, and where they perform best.

- What Are Rib Rollers?

- Types of Rib Rollers for NTM Machines

- Benefits of Adding Ribs to Metal Roof Panels

- How NTM Rib Rollers Work

- Changeover and Maintenance Tips for NTM Rib Roller Systems

- Quick FAQs

- The Lowdown on NTM Rib Rollers

What Are Rib Rollers, Anyway?

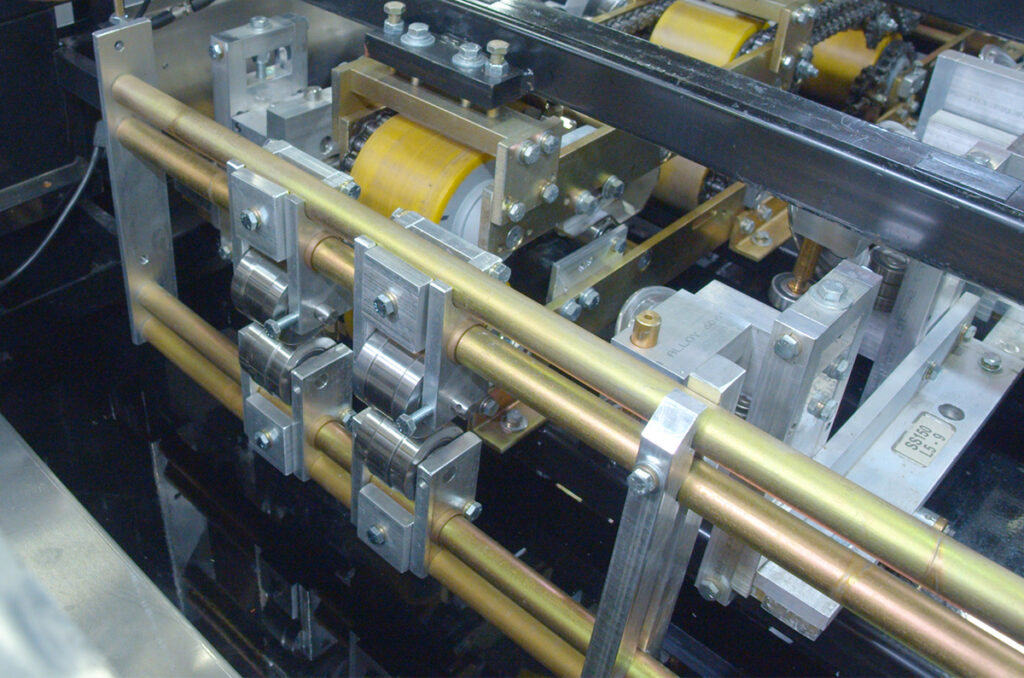

Rib rollers sit just behind the shear in your rollforming machine, on a separate frame—not to be confused with the profile tooling that actually forms the panel.

Their value? They add decorative ribs in the panel’s flat surface, boosting stiffness and hiding minor imperfections like oil canning.

These assemblies include both top and bottom rollers. For striations, they share the same frame, and multiple rollers can be added depending on the number of striations you want.

Types of Rib Rollers for NTM Machines

When you buy a new NTM roof panel machine (except the 5VC Crimp), you get to choose one matching pair of rib rollers—one top and one bottom—for your setup. Here’s what’s available:

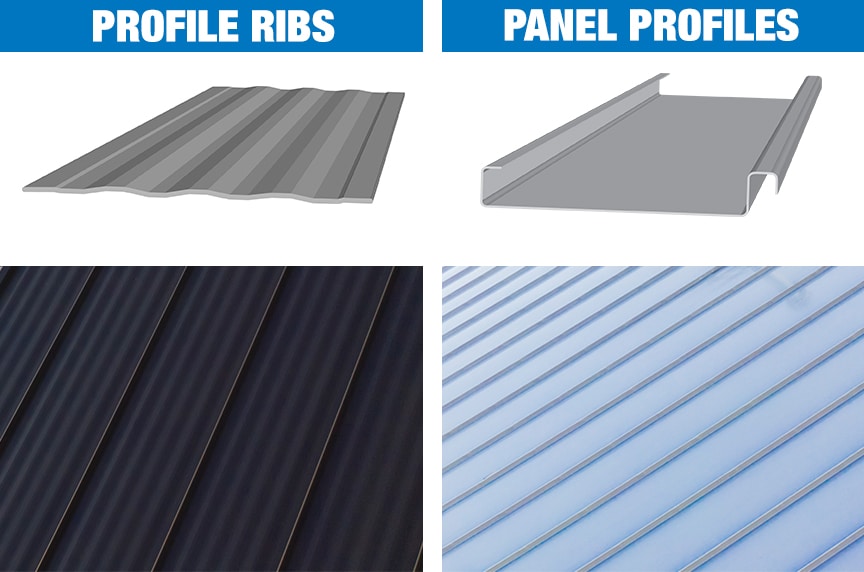

- Bead Ribs

Rectangular indentations that come in standard (1.05″) or wide (2″) options. Great all-around styling pick for machines like SSQ II, SSR, and SSH. - Pencil Ribs

Rounded, half-circle style ribs in small (0.38″) and large (0.68″) sizes—available for SSQ II, SSR, and SSH. For FWQ Flush Wall/Soffit profiles, try using small pencil or small V ribs, as the large versions may cause the panel to bow. - V-Ribs

A sharper look that’s basically a V-shape indentation. Available as small (0.37″) and large (1.02″) for the same machines (SSQ II, SSR, SSH). - Striations

A wave-like pattern created using offset rollers to give the panel a wavy texture—and disguise oil canning or imperfections beautifully. Fully adjustable in depth and width, subtle or more pronounced. Works with SSQ II, SSR, SSH—and the 5VC has its own variation. - Clip Relief

Not technically a rib, but super useful. A raised edge that ensures clip or fastener heads don’t dent the panel. Mounted on an eccentric shaft so you can slide it out of the way when not needed.

Benefits of Adding Ribs to Your Metal Roof Panel

- Structural Strength: Adds rigidity to the panel field.

- Visual Makeup: Hides minor coil defects or machine slips; striations are especially handy for camouflaging oil canning.

- Aesthetic Flexibility: Choose the style that best fits job requirements or architectural needs.

- Panel-Specific Use: For flush wall or soffit panels like the FWQ100 or FWQ150, NTM recommends small pencil or V‑ribs for better stability and look.

How NTM Rib Rollers Work

- Engage/Disengage Easily — The top roller rides on an eccentric shaft, so you can drop it in or lift it out as needed.

- Slide to Position — Adjust side-to-side to set where the ribs fall on your panel width.

- Depth Control — Fine-tune shallow or deep ribs depending on the visual or structural effect you want.

- Striation Adjustability — Slide the whole assembly left or right to adjust how wide or narrow the striation band runs across the panel.

Changeover and Maintenance Tips for NTM Rib Roller Systems

- Optimize with Multiple Frames: Investing in a second rib roller frame can save time and labor by allowing you to preset configurations and swap them quickly between jobs.

- Keep It Clean: Wipe down rollers with acetone whenever they look dirty. Staying on top of cleanliness maintains form accuracy.

- Slide Bars Need Grease: Keep them lightly greased for smooth operation.

- Store Smart: Keeping your machine covered and indoors helps prevent scratches or dings that could damage roller surfaces.

- Safety First: Always use proper training, manuals, and video resources. Never operate without guards in place—serious injury could result.

FAQs

What are the benefits of adding rib rollers?

- Structural strength

- Improved appearance

- Aesthetic options

- Panel-specific use

What types of rib rollers are available for NTM machines?

- Bead Ribs – Rectangular indentations, standard (1.05″) or wide (2″).

- Pencil Ribs – Rounded, half-circle ribs; small (0.38″) or large (0.68″).

- V-Ribs – V-shaped indentation; small (0.37″) or large (1.02″).

- Striations – Wavy, textured lines that hide oil canning. Adjustable depth/width.

- Clip Relief – Not a rib,but prevents clip/fastener heads from denting panels. Mounted on an eccentric shaft to disengage when not needed.

The Lowdown On NTM Rib Rollers

Rib rollers are a small but mighty upgrade for NTM portable roof panel machines. They’re not just about aesthetics—they bring structural enhancement, improved tolerance for coil flaws, and even installation convenience. Whether you’re after bead, pencil, V-ribs, striations, or clip relief, NTM’s options give you flexibility for whatever your project calls for.

If you’re still unsure which rib best suits your application—or want help matching ribs to your machine or project—reach out to an NTM rollforming specialist.