Best Portable Seamless Gutter Machines in 2025

Whether you’re a gutter installer ready to run your own operation or a roofing contractor looking to expand your services, portable seamless gutter machines can give you total control of your operation. These machines let you create custom-length seamless gutters right at the job site, fabricating the best quality custom gutters so you get a perfect fit on every home. They also give the rooflines a sleek appearance.

In this article, we break down the top residential gutter rollforming machines of 2025, comparing features that matter to contractors. We’ll explore various gutter profiles and the practical advantages seamless options offer over traditional sectional gutters. Whether you work with K-style, half-round, or fascia gutters, this overview covers the machines worth thinking about.

By the time you finish, you’ll have a thorough understanding of seamless gutters, and the offerings of top brands.

Types of Seamless Gutter Systems

Home gutters generally come in a few profile types. The K-style gutter is by far the most popular in North America. It has a flat back (mounts directly to a fascia board) and a decorative front that resembles crown molding. Thanks to their flat bottom and angled sides, K-style gutters can carry roughly twice the water volume of half-round gutters of the same width. The trade-off is that the inner angles can collect debris, making K-gutters a bit harder to clean than a smooth half-round style.

Half-round gutters are the traditional semicircular gutters. Their U-shaped profile doesn’t have interior corners, so debris doesn’t get stuck in corners as in K-gutters, and cleaning can be easier. However, half-round gutters typically can’t mount flush against a flat fascia; they require brackets or hangers since the curved side won’t sit flat on the fascia board. Half-rounds also carry less water than K-style of equivalent width, so they’re primarily used in regions with mild rainfall or for aesthetic preference (for example, many homeowners choose copper half-rounds for an ornate, classic look).

Fascia gutters are built with a tall, flat face that acts as both the gutter and the fascia board. These are often used on homes with no exposed rafter tails or separate wooden fascia boards – for example, some southwestern or modern-style homes where the gutter itself forms the fascia cover. Fascia gutters present a sleek appearance, blending into the roof edge, and because they have no seams (always custom roll-formed in one piece), there are no joints to leak. The downside is that professionals must install them on-site; you can’t buy sectional fascia gutter pieces at a home store.

Prefabricated vs. Seamless Gutters

For contractors weighing gutter installation using factory-manufactured sections versus fabricating their own seamless gutters, it’s important to understand the benefits of on-site rollforming. Sectional traditional gutters (usually sold in 10–20 ft aluminum or vinyl pieces) have more joints, which means more potential leak points – every seam is a weak spot prone to dripping and debris buildup. Over time, the sealants can fail, and trapped leaves at joints can cause corrosion or sagging. These prefab gutters also need more frequent maintenance and replacement sections; they might last only 10–15 years, whereas seamless gutters can last anywhere from 25 to 100 years, depending on material. In cold climates, sectional gutters are also more prone to ice damage at the joints.

Aesthetically, seamless gutters have a smoother, sleeker look. Traditional segmented gutters tend to have slight misalignments or sag at connections, which can be an eyesore, especially on long rooflines. Seamless gutters maintain their shape, and they’ll only have seams at inside/outside corner miters or where downspouts connect. Fewer seams look better and reduce clogs – leaves are less likely to snag compared to a sectional system with multiple ridges and joints.

That said, sectional gutters do have the advantage of lower upfront cost to the homeowner, so if cost is a major driver, seamless may be a harder sell. Sectional gutters come in a variety of materials (aluminum, steel, copper) and standard profiles (K-style or half-round). They’re usually available at Home Depot or Lowe’s.

By contrast, seamless gutters fabricated with portable rollforming machines will form each gutter to the exact length of the roof edge in one continuous piece. This process requires an upfront investment in a gutter machine, but yields a higher-quality result for the homeowner. Seamless gutters are custom-fit on-site and usually made from heavier-gauge aluminum or steel that lasts longer. While there’s a market everywhere, you’ll see them a lot on custom and higher-end homes.

The main con of seamless gutters is the higher cost: The machine-formed gutters themselves cost more per foot, and you have the labor of the crew running and installing them. However, homeowners get a product that lasts decades longer and protects the home better (fewer leaks, less frequent cleaning, less water damage to walls/foundations). And for homeowners with higher-end homes, the look of seamless gutters is worth the higher price.

For contractors, investing in a portable gutter machine can open new business opportunities. It lets you offer homeowners on-site custom gutters with quick turnaround, and you can fabricate gutters in any length needed without relying on pre-cut stock. As New Tech Machinery notes, owning a gutter machine allows you to take on jobs that require special profiles or colors and to service higher-end customers who demand seamless systems.

The bottom line: Portable rollforming machines give gutter pros a competitive edge, and they provide homeowners with a superior gutter system compared to store-bought sectional pieces.

Leading Portable Gutter Machine Manufacturers (2025)

A handful of manufacturers dominate the industry when it comes to portable seamless gutter machines. Below, we review the best machines from the top companies— Eastside, Englert, Grover, KWM, and New Tech Machinery—and compare their capabilities in gutter size, material, speed, controls, and portability. The companies are listed in alphabetical order for easy reference.

Eastside Machine Company

Eastside Machine Company (based in Fargo, ND) has been building portable rollformers since 1960. Eastside specializes in machines for fascia-style gutters – a niche where they are a market leader. Their line-up includes the EM 4½″, 5½″, and 7½″ Fascia Gutter Machines, as well as their Eagle 5″ K-style machine.

Eastside’s fascia gutter profiles produce a smooth-faced gutter that doubles as the fascia board – commonly used on homes without pre-installed fascia, or whenever a larger-capacity gutter is needed in a limited space. For example, the EM 5½″ fascia gutter is often used with 2″×4″ truss tails in place of a wooden fascia board.

All Eastside gutter machines are built with heavy-gauge steel frames and feature fully driven rollforming stations. The forming rollers are nitrocarburized and case-hardened (QPQ) steel for strength and corrosion resistance.

Beyond fascia gutters, Eastside offers the Eagle 5″ K-Style machine.

Notable features: Eastside’s machines are known for their fascia-style gutters.

Warranty: Two-year limited warranty

Eastside Machines:

- EM 4½″, 5½″, and 7½″ Fascia Gutter Machines

- Eagle 5″ K-Style Gutter Machine

Features:

- Nitrocarburized steel forming rollers

- Fully driven forming stations

- 36 ft/min forming speed

- Supports up to 26-gauge steel, .032” aluminum, 16-20 oz copper

- Trunnion coil cradle for easy coil flipping

Englert Inc.

Englert Inc. (New Jersey) has been a well-known supplier of metal roofing and gutter systems since 1966. Englert’s line of gutter machines, branded “MetalMan”, are often sold with specialty gutter systems that Englert markets, such as the LeafGuard® one-piece covered gutter and the RainPro high-capacity gutter. In fact, Englert manufactures dedicated machines for those proprietary profiles in addition to standard K-style equipment.

For conventional gutters, Englert offers:

- MetalMan 555 – a 5″ K-style seamless gutter machine.

- MetalMan 660 – a 6″ K-style machine (their flagship for standard residential).

- MetalMan 650 – a combo 5″/6″ machine (versatile dual-size capability).

- MetalMan 770 – a 7″ gutter machine for commercial box gutters (7″ box profile).

- RainPro–a 5″ high-capacity proprietary profile gutter machine

The LeafGuard machine produces Englert’s patented one-piece gutter with integrated hood, and the RainPro machine produces an oversized gutter with a narrower profile height (a unique product Englert offers for more water capacity without a huge fascia presence).

The rack-and-pinion guillotine shear makes manual cutting smoother and reduces the effort needed to shear heavy steel. Englert also provides marketing support for contractors who become LeafGuard or RainPro dealers.

Warranty: five-year limited parts and labor.

Popular models:

- MetalMan 555 (5″ K-style)

- MetalMan 660 (6″ K-style)

- MetalMan 650 (Combo 5″/6″)

Features:

- 45 ft/min forming speed

- Minimal roller adjustment for various materials (up to 24-gauge steel)

- Lifetime-guaranteed drive rollers

- Easy manual rack-and-pinion shear

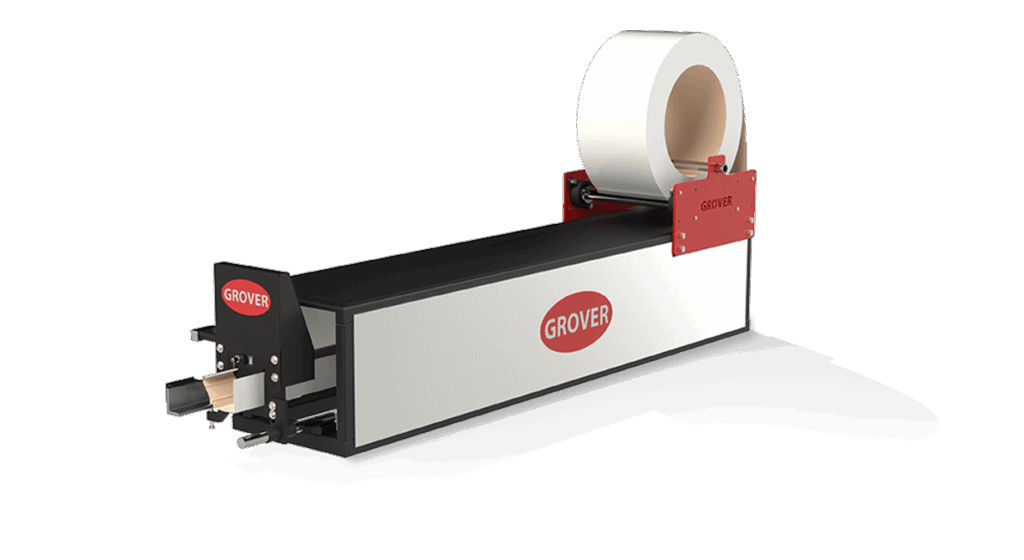

Grover Machine

Grover Machine (St. Louis, MO) has been producing rollforming equipment since 1958, with a specialty in gutter, downspout, and elbow machines. They offer a wide range of gutter profiles and sizes:

- Portable K-style machines in both 5″ and 6″ sizes.

- Portable half-round machines in 5″, 6″, and even 8″ sizes.

- Portable fascia gutter machines in 5″ and 6″ sizes.

- In-plant (stationary) machines for high-volume production in 5″, 6″, 8″ K-style.

Grover’s popular models include the Pro5-K (5″ K-style) and Pro6-K (6″ K-style) for residential gutters, as well as the HR6 (6″ half-round) machine. The design philosophy at Grover has been a bit different from some competitors: They use hardened chrome-plated steel drive rollers instead of polyurethane, and each forming station is spring-loaded to automatically adjust to material thickness. This means the machine can still accommodate different metals without manual adjustment, and the spring tension and grip of the steel drive rollers are sufficient to hold alignment, much like the poly rollers do on other brands.

Warranty: five-year material and workmanship warranty.

Key offerings:

- Pro5-K (5″ K-style)

- Pro6-K (6″ K-style)

- HR6 (6″ half-round)

Features:

- Chrome-plated, spring-loaded steel rollers

- 30 ft/min forming speed

- Supports aluminum, steel, and copper

Grover’s half-round machines are also notable. The 6″ half-round (Model HR6) is longer at 169″ (to accommodate the gradual forming of the semicircle) and interestingly uses a 3 HP motor, likely to handle heavier material and additional forming stations. Even so, it maintains ~30 fpm production speed. The 8″ half-round (Model HR8) caters to commercial or high-capacity residential needs (where huge volumes of water need to be moved).

Notable features: Grover machines might not have fancy electronics or the highest speed, but they are built to last and stay in alignment. Additionally, Grover offers a full complement of gutter system equipment (e.g., separate machines for downspouts and elbows), so a contractor can source an entire package of rollforming machinery from one place.

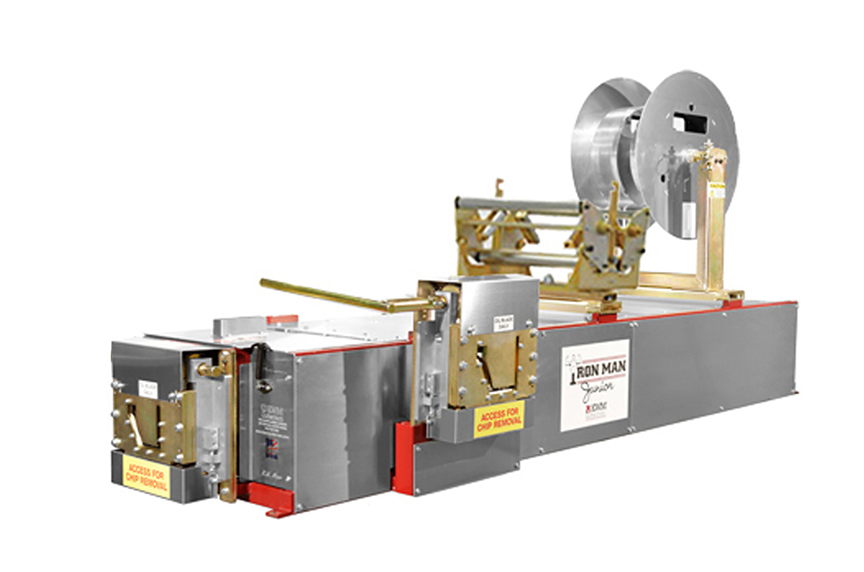

KWM Gutterman Inc.

KWM Gutterman (Illinois) is one of the largest names in the gutter machine business. Founded in 1983 by Karl W. Minor, Sr., KWM’s flagship product line is the IronMan series of gutter machines. Made in the U.S.

KWM’s offerings:

- IronMan 5″ (standard 5″ K-style) – also available in a shorter “Junior” version.

- IronMan 6″ (standard 6″ K-style) – also in Junior version.

- IronMan 5″/6″ Combo, which can be configured for either 5″ or 6″ on the same machine (also a Junior combo).

- IronMan 7″ and 7″/8″ Combo (for commercial 7″ K or 7″/8″ combo; 7″/8″ combo can switch between 7″ K and 8″ half-round? Actually, 7/8 Combo likely means 7″ K and 8″ K, or 7″ K and 8″ K – but KWM’s list shows 7/8, possibly 7″ K and 8″ K).

- IronMan Fascia gutter machine (for producing fascia gutter profile).

- IronMan 6″ Half-Round (Gen 2) machine.

Like NTM, which innovated the system for portable gutter machines, IronMan machines use the polyurethane passive drive system. The forming rollers are free-floating stainless steel with hard chrome plating, which means the machine can handle different thicknesses with little or no adjustment.

KWM equips the IronMan with push-button controls at both entry and exit. The shear is a guillotine style: front-pull manual cut for both 5″ and 6″ profiles (the combo machine has two separate shear blades mounted for each size). The IronMan’s frame is a welded tubular steel design..

KWM also offers the IronMan Junior series, which are lighter-weight, slightly stripped-down versions of the 5″, 6″, and combo machines. For instance, a 6″ Junior weighs under 1000 lbs, making it easier for one person to maneuver. They run at a similar speed but may have fewer forming stations or a smaller motor (often 3/4 HP as well, but a bit different in construction).

Beyond K-style, KWM’s Fascia gutter machine provides the ability to make the flat-face gutters (likely in sizes around 4.5″ or 5.5″, similar to Eastside’s profiles). And the 6″ Half-Round Gen 2 machine is KWM’s solution for half-round production, using their same poly drive technology in a machine dedicated to the half-round shape.

Warranty: three-year parts and labor on all mechanical components and one year on electrical components.

Featured models:

- IronMan 5″ and 6″ K-style

- IronMan Combo (5″/6″)

Features:

- Polyurethane drive rollers

- 35 ft/min forming speed

- Supports materials up to 24-gauge steel, .032” aluminum

Notable features: KWM Gutterman provides a full range of reliable gutter machines backed by decades of manufacturing experience and solid warranty support.

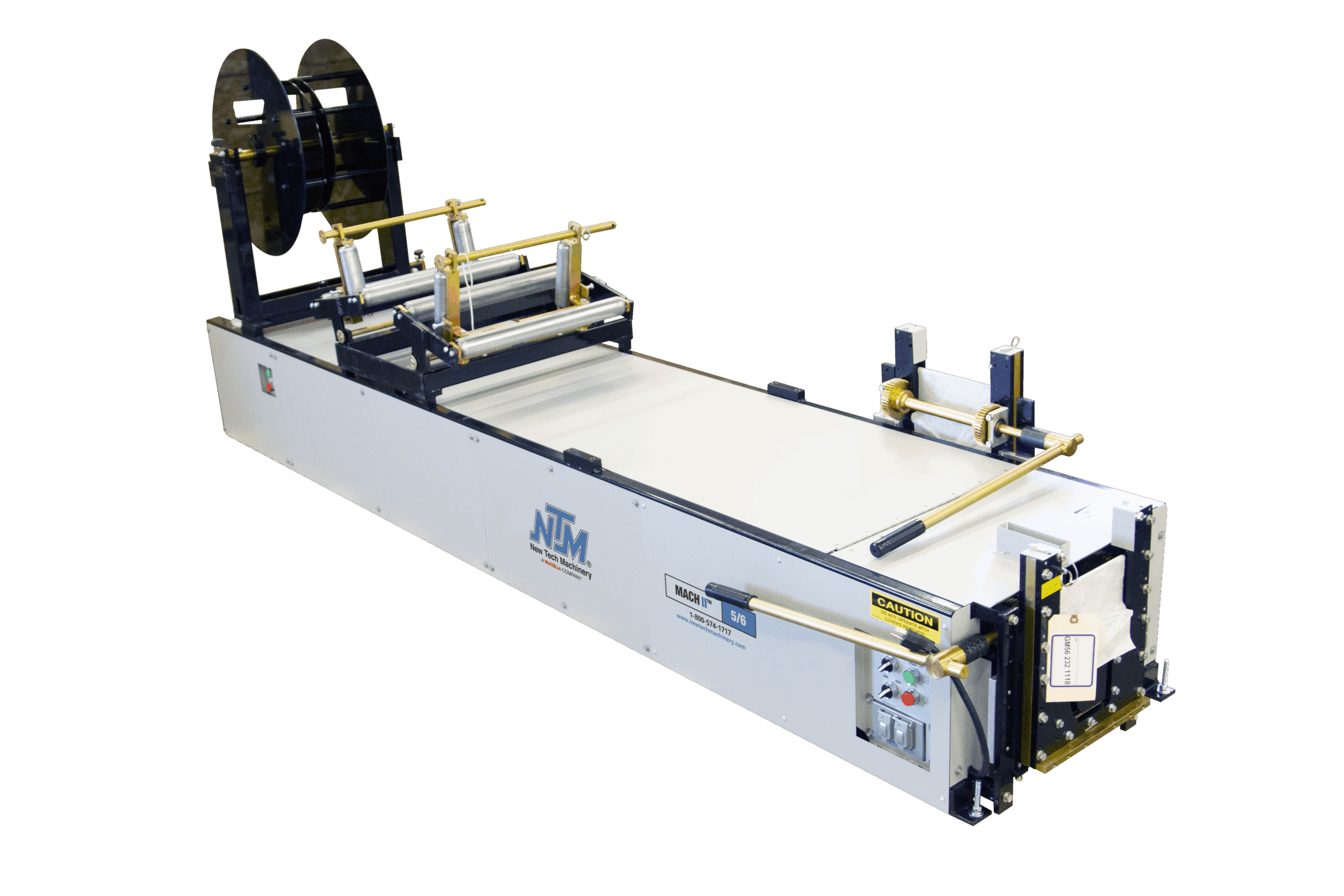

New Tech Machinery (NTM)

New Tech Machinery (NTM) is a top manufacturer that has been innovating in portable rollforming since the early 1990s. NTM’s MACH II gutter machines are widely regarded and often considered the most copied design in the industry. NTM offers the Mach II in three primary configurations:

- 5″ Mach II – for 5″ K-style gutters.

- 6″ Mach II – for 6″ K-style gutters.

- 5″/6″ Mach II Combo – a combo machine that can do both 5″ and 6″ by adjusting tooling.

The Mach II series is known for its polyurethane drive roller system (NTM was the first to introduce this into portable gutter machines), which provides superior material traction without scratching the painted coil and allows the machine to run without material in it (no coil is needed to “lock” rollers during transport). NTM also offers the industry’s best warranty, which currently is 3 years parts / 3 years labor, plus lifetime on major components like the drive rollers and forming rollers.

Performance-wise, Mach II machines are a bit faster than others: They can run at about 50 feet per minute (15 m/min). All Mach II machines can handle 30-gauge to 24-gauge steel, .019″ to .032″ aluminum, and 16oz to 20oz copper (3/4 hard), which covers the full range of standard gutter materials.

NTM equips the machines with a manual shear that uses hardened tool steel blades. Standard controls are simple but effective: a forward and reverse switch with a jog function, and emergency stop buttons.

An optional remote control is available, which is a 4-button remote allowing one-person operation from the far end of the gutter – very handy when running long pieces solo. NTM also offers an optional EZ-Counter computerized length controller that can automate the cutting process – you can program specific lengths and quantities, and the machine will advance and cut the gutter automatically to those specs. This is an add-on that some high-volume users get to increase efficiency.

Portability and convenience features on the Mach II include things like a removable power pack (so you can service the motor or electronics easily), 12V battery power option (so the machine can run off a vehicle battery/inverter on sites with no electricity), and adjustable coil stands.

NTM emphasizes training and support – as a manufacturer, they provide free training for new machine owners at their Colorado facility and have a robust support network. For many contractors, the NTM Mach II has been the go-to machine for starting a seamless gutter business due to its combination of speed, build quality, and support resources.

Warranty: Three-year limited parts and in-house labor warranty. Limited lifetime protection against separation on drive rollers.

Key machines:

- Mach II 5″, 6″, and Combo (5″/6″)

Features:

- Polyurethane drive wheel system

- 50 ft/min forming speed

- Supports steel, aluminum, copper

- Optional EZ-Counter computerized length controller

- Industry-leading warranty

Notable features: The speed (50 fpm) is a key differentiator – Mach II is one of the fastest gutter machines, which means you can run long gutters quickly and boost job productivity. Also, NTM’s focus on technology and options sets them apart: the availability of a computerized length controller and remote operation appeals to those who want more automation.

Lastly, NTM’s comprehensive warranty and the fact that many competitors benchmark against NTM’s design (“most copied machine”) speaks to the trust they’ve earned.

Comparison Chart of Leading Gutter Machines

To summarize the key differences, the table below compares the primary portable gutter machine offerings from each manufacturer reviewed above. It highlights the gutter profiles each can produce, typical forming speeds, supported materials, control systems, and notable features related to portability and user-friendliness.

| Notable Features | Gutter Profile & Size | Forming Speed | Materials Supported | Controls/ Operation | Notable Features | Warranty |

|---|---|---|---|---|---|---|

| Eastside Machine EM 5½″ Fascia | 5.5″ Fascia gutter (flat fascia style); also 4.5″ and 7.5″ fascia, 5″ K-style | 36 ft/min (11 m/min) | 26–29 ga steel, .032″ aluminum, 16–20 oz copper | Push-button with entry jog; manual guillotine shear | Gutters double as fascia board, often used with 2″x4″ truss tail | 2-year limited |

| Englert | 6″ K-style seamless gutter (also offers 5″ K, 5″/6″ combo, 7″ box; LeafGuard & RainPro profiles) | ~45 ft/min (13.7 m/min) | 30 ga – 24 ga steel; .019″–.032″ alum; 16–20 oz copper | Drum switch (fwd/rev) with jog; dual emergency stops | Specialty gutters for LeafGuard & RainPro proprietary profiles. | 5-year limited |

| Grover Machine | 6″ K-style gutter (also 5″ K; 5″,6″ fascia; 5″,6″,8″ half-round profiles) | ~30 ft/min (9 m/min) | Aluminum, steel, copper (up to ~24ga steel, .032″ alum typical) | Push-button controls (fwd/rev jog); manual shear | Hardened chrome-plated steel drive rollers with spring-loaded forming stations. | 5- year material & workmanship |

| KWM Gutterman | 5″ K-style and 6″ K-style, fascia, half-round | ~35 ft/min (10.6 m/min) | Max: 24 ga steel (painted/galv.); .032″ aluminum; 16–20 oz copper (3/4 hard) | Push-button controls at entry & exit with “jog”; manual front-pull shear | Junior series– lighter weight, smaller size for tight spaces. | 3-year parts/labor warranty on mechanical components. 1 year on electrical components. |

| New Tech Machinery | 5″, 6″, & 5″/6″ Combo K-style | 50 ft/min (15 m/min) approx. | 30–24 ga steel; .019″–.032″ aluminum; 16–20 oz copper | Forward/Reverse switch with jog; manual lever shear (optional auto-counter) | Optional computerized length controller and wireless remote. | 3-year limited parts and in-house labor. Limited lifetime protection against separation on drive rollers. |

The Bottom Line

Each of these machines has its strengths and differentiators. The best choice ultimately depends on your business needs: the profiles popular in your region, the volume of work, your budget, and whether features like combo sizing or automation will benefit you.

By understanding the specs and capabilities outlined above, residential contractors can make an informed decision and invest in a gutter machine that will serve them for years to come – producing quality seamless gutters that keep customers’ homes dry and protected.

For information about NTM’s Mach II Portable Seamless Gutter Machines, or any of our portable rollformers or accessories, contact us. An experienced account manager will be happy to assist you.