In every industry, there are safety standards and certifications to ensure that products will perform to the best of their ability and reassure your customers that they are getting a safe and proven product. There are also inspections and audits for portable rollformed metal roof panels to ensure you’re providing a safe and high-quality product.

To provide your customers with the right information about an NTM machine-manufactured roof panel, you need to understand what happens in our inspection process, what a UL construction number is, and what is expected of you as a contractor to keep up with your UL certification.

At New Tech Machinery (NTM), certain metal roof panel profiles we offer are Class 90 compliant. However, what does that mean? We thought it was important to discuss what goes into inspecting our panels for UL compliance and how you can get UL certification for your portable rollforming machine.

In this article, we’ll help you understand:

- What is Underwriter Laboratories

- What the inspection process looks like for NTM panel profiles

- What is a UL construction number

- What to do if you want to get panels certified with UL

What Is Underwriters Laboratories?

Underwriters Laboratories (UL) is a global safety certification company. It is a world-renowned independent company that conducts safety and quality tests on various products, materials, and systems for many industries, including:

- Automotive and Mobility

- Construction and Engineering

- Energy and Utilities

- Financial Services and Payments

- Government Services

- Healthcare and Life Sciences

- Industrial Products and Systems

- Life Safety and Security

- Materials and Chemicals

- Retail

- Technology and Electronics

In 1894, William Henry Merrill Jr founded the Underwriters Electrical Bureau. It wasn’t until 1901 when UL incorporated as Underwriters’ Laboratories Inc. in Illinois, and in 1903 it published its first Standard for Safety. Underwriters Laboratories and its staff have developed over 1,000 standards for safety.

There are various ratings and UL marks for products. Common marks include:

- UL Listed – This mark is often used on computer equipment, appliances, fuses, and many more products. To have this mark means that “UL found that representative product samples met UL’s requirements.” Products with UL Listed marks are end-products or complete components for factory and field installation.

- UL Classified – This mark is for manufacturer’s products that UL evaluates and finds compliant with their requirements for a particular risk, performance under certain conditions, compliance with regulatory checks, or compliance with specific standards. Products with this mark are covered by UL’s Follow-Up Services Program, ensuring they’re compliant with UL requirements.

- UL Recognized – It’s a less common mark and is mainly used on individual parts of a bigger product or system. The components covered under this mark are typically installed inside a factory for use in another device, system, or end-product—for example, switches or power supplies.

Why Are NTM Metal Roof Panels Only UL Compliant?

What we offer clients are UL-compliant panels according to the specifications set forth by UL. In this case, compliance means that our panel profiles are the correct dimensions specified by UL standards for certain construction numbers. It’s also important to remember that engineering is not inherent to a portable rollforming machine.

At the New Tech Machinery facility in Denver, a UL representative conducts audits to examine the panels produced by our roof panel machines to check that the panel’s dimensions match what our factory drawings depict. This inspection ensures that our manufactured panels remain in compliance for use in the UL 90 Construction Numbers.

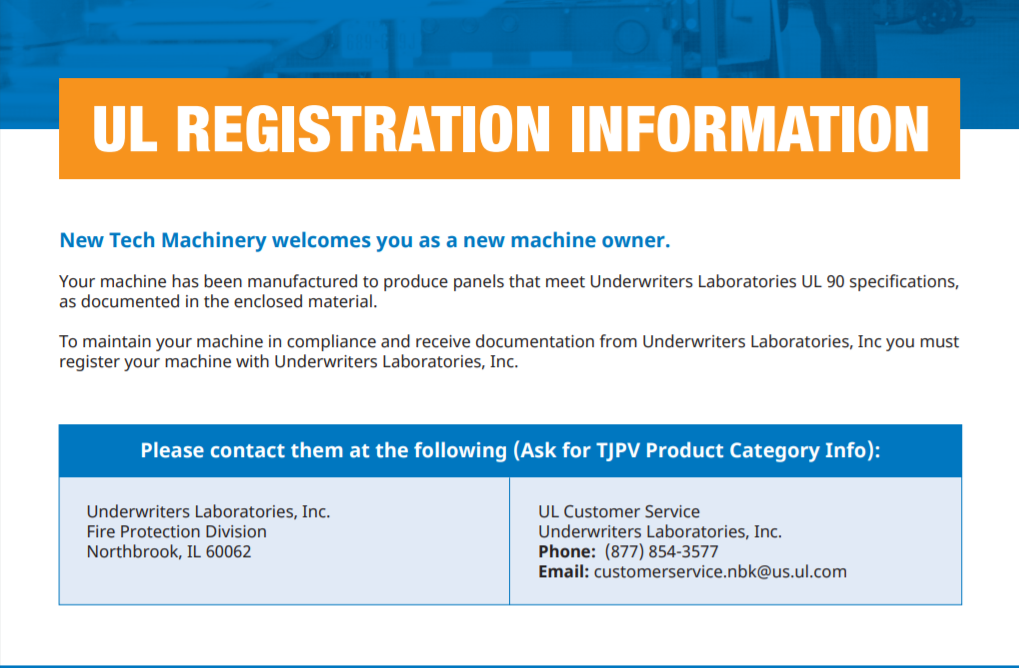

By providing you with UL-compliant metal roof panels, we’ve already taken the first step if you choose to continue getting your panels certified. It’s our promise to you that we have remained in compliance with that specific panel test, and you’re getting the documentation of that compliance. You have to register each machine with UL for the construction numbers you want to remain in compliance.

Please note, field-formed panels have demonstrated compliance with UL 90 Construction Numbers WHEN a UL certificate accompanies the machine producing the panel. New Tech Machinery does not provide any testing on your panels.

You can find more information on which panels are UL compliant and read through all the documentation provided by UL here. To maintain your machine in compliance with UL and receive documentation from them, you must register your machine with UL.

Now that you understand the importance of keeping our panel profiles in compliance with UL specifications, let’s look at the actual process our panels go through to remain compliant.

New Tech Machinery and the UL Inspection Process

To receive UL compliance, New Tech Machinery has to undergo a quarterly process with UL, which we pay for, to provide you a better product. What does this process look like?

An inspector from Underwriter Laboratories comes out every quarter to check and verify that our portable rollforming machines are producing panels in compliance with UL Construction Numbers associated with that panel profile. There are UL booklets that specify which material to use and the required panel width to be considered compliant. The inspection typically happens using 24 gauge steel.

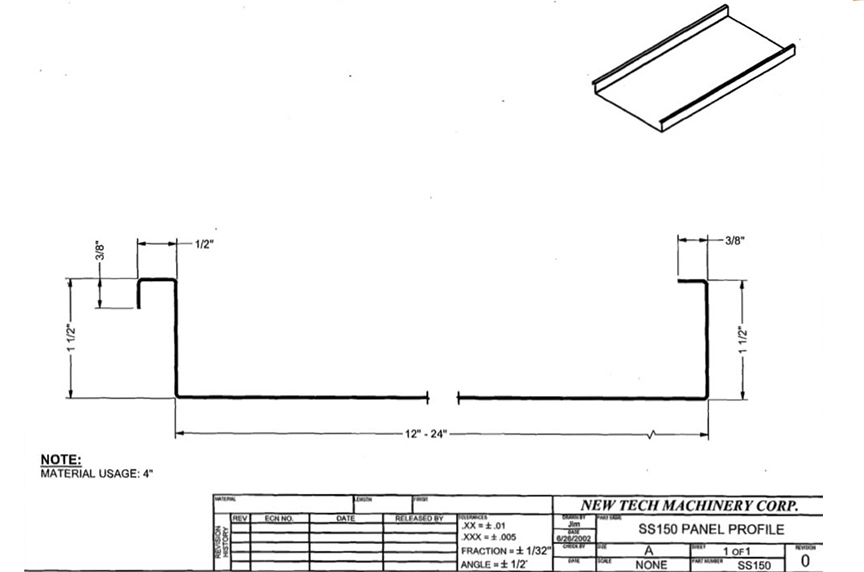

When the inspector shows up, someone at New Tech Machinery provides a panel (a different profile every time) and the UL book containing the UL Construction Numbers for that panel to track the dimensions. The inspector measures and documents all the dimensions of that panel to ensure that our profile drawing matches the actual panel measurements.

The inspector checks the base metal thickness and dimensions. Every bend, thickness, width, and height must be taken into account and verified that the panel and its legs match those measurements listed on the NTM cutsheet. UL does not check or perform any testing on the actual machines.

At NTM, we only have inspections done to remain in compliance with specific UL Class 90 Construction Numbers, but other companies and contractors may provide additional testing like air infiltration, water penetration, hail impact, UL and ASTM wind uplift, etc. Be sure to check with your metal sheet or coil supplier about the testing they may offer for your metal roofing systems. An architect or engineer can help specify which testing you need, depending on the project.

Not all of our profiles are UL compliant. The only panel profiles inspected to remain UL compliant are:

- SS100

- SS150

- SSQ200

- SSQ210A

- SS450

- SS450SL

- SSQ550

- SSQ675

- FF100

- SSQ275

When you purchase an NTM machine, we’ll supply you with a letter explaining how to register your machine with UL to obtain certification. Also, check your documentation for other important information regarding your portable rollforming machine, including warranties, machine manual, and UL compliance paperwork with UL construction numbers listed.

What Is a UL 90 Construction Number?

When you look at the New Tech Machinery UL test booklets, you’ll see on some of them “Construction No. 575” or “Construction No. 529.” What do those numbers mean?

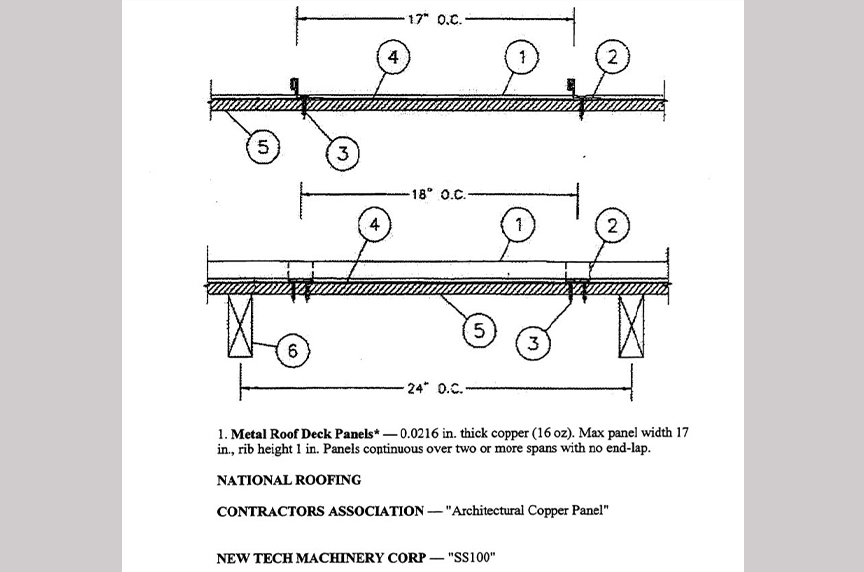

The UL Construction Numbers are more like a blanket test that covers multiple manufacturer’s panel systems that are similar. If those panels are installed per the requirements of the particular UL 90 Construction Number, then all the panel profiles listed under that construction number will meet UL 90 standards when tested. However, there’s no seal or test report when you get a UL 90 Construction Number.

The UL 90 Construction Number basically tells you that if you put those panels on per the specifications of that Construction Number, they will be compliant with UL 90 requirements. It describes the full roof system as tested to achieve the UL 90 rating.

UL 90 Construction Numbers are based on UL580 test standards. They list everything that panel is compliant for in regards to a number of qualifications, including:

- Which type of substrate assembly is used and its minimum thickness(plywood, metal deck, open framing)

- What panel material is used (aluminum, steel, or copper)

- How wide of a panel can be used

- Insulation type and thickness (if applicable)

- Which type of clip is required to be used

- Which fasteners are used to connect panels and how many (screws)

- Types of joists used and the spacing of those joists

- If the decking is required to be sealed or screwed down instead of nailed

Another point worth mentioning is that with some UL 90 Construction Numbers, uncommon practices may be used in these installation methods that you want to be mindful of. Just consult with your metal coil or sheet supplier as to the installation methods they recommend.

Why and How to Obtain UL Certification for My Portable Roof Panel Machine Profiles?

For contractors, manufacturers, and anyone providing metal roof panels to customers for installation, providing a UL-certified panel is a significant benefit. It does require some work to keep that certification, though. Every six months, you need to renew your certificate to remain in compliance and certified with UL. On our website, you can find the registration document with instructions on how to make sure your machine remains compliant with UL.

Why is it important to keep your panels certified? As a machine owner, it’s up to you to ensure you’re running panels in tolerance of UL specifications. It tells customers that your product is going to perform to the specifications and requirements set forth by UL. However, if you provide misinformation and your panels aren’t UL-certified, you could be held liable for any problems that may arise. Once you obtain the certificate, it has to be with your portable rollformer at all times.

Why might it be a good idea to get UL certification for your portable rollforming machine?

- It tells your customers that you’re dedicated to their safety and the quality of the products you offer them.

- It offers your customers a sense of security.

- Because UL is such a well-known and reputable company, having your product associated with UL is a great way to set yourself apart from the competition.

- It provides customers with confidence that they’re getting what they pay for. It tells them you’re standing behind your product and helps protect your brand’s reputation.

So what do you have to do to make your portable rollforming machine’s panels UL-certified?

Your machine will go through a similar process as New Tech Machinery when checking panels for UL compliance. First, you’ll be required to apply with UL for certification, pay any fees, and enter their follow-up service program. With this follow-up service, a UL representative will check your machine periodically to verify that your portable rollforming equipment is still producing panels that are compliant and representative of the original machine manufacturer’s UL drawings and specs.

How can you make sure your machine remains in compliance with the factory dimensions of the panel? Keeping your machine well maintained and properly adjusted can help ensure that your panel doesn’t fail inspection. Also, checking your panel dimensions frequently throughout the rollforming process will help ensure you maintain the proper tolerances till job completion. If you’re unsure how to make adjustments or need maintenance assistance, our service team is here to help.

Final Thoughts

Industry standards are designed to ensure your product keeps up with the latest requirements and is reliable and safe for your customers. That’s why it’s vital to understand what kind of UL inspections and compliance our portable roof panel machine profiles go through.

Remember that although we provide UL compliant panels, New Tech Machinery is still only a machine manufacturer, and we’re only inspecting one aspect. You must certify your machine and keep your certification up to date and with your machine at all times if you want to install UL-certified panels; otherwise, you’re only providing a UL-compliant panel.

At New Tech Machinery, we understand the importance of keeping your customer’s loyalty and trust. This means knowing what inspections your machine’s panels have gone through and how it applies to you and your customers.

If you have any questions about our UL inspection process, portable roof panel machines, or panel profiles, please contact us, and one of our rollforming specialists will be happy to help.