How to Maintain Your NTM SSQ3™ MultiPro

If you’ve run NTM machines before, the basics of NTM’s new SSQ3™ MultiPro maintenance will feel familiar. The goal is the same: keep it clean, keep it lubricated, and catch small issues before they turn into downtime. However, given some of its new time-saving features, you’ll find a few differences in maintaining the SSQ3. This article combines standard NTM best practices with what’s unique to the SSQ3.

We’ve broken this article down for you and your crew to use as a practical, field-ready reference. Always refer to your machine’s manual first for procedures and safety guidelines.

Why Maintenance Matters

- Extends the life of mechanical and electrical components

- Improves cut quality and panel finish

- Reduces unplanned service calls and lost time

- Keeps operators safer and more efficient

Table of Contents

- What Maintenance Tasks are Common to All NTM Roof Panel Machines?

- What’s Different on the SSQ3? Key Items to Watch

- SSQ3 Maintenance FAQs

- Practical Lubrication Tips

- SSQ3 Quick Checklist

- Maintenance Interval Chart

- Troubleshooting

What Maintenance Tasks are Common to All SSQ Roof Panel Machines?

Use these intervals as a general guideline. Adjust by environment and runtime; some contractors may use their machine a few times a month, while others run it daily. When in doubt, check it weekly for maintenance.

Daily or every production day

- Shear lubrication: On the SSQ™ and SSQ II™, lightly spray both faces of top blades, bottom dies, and male/female dies about every 30 cuts or when they look dry.

- male/female dies about every 30 cuts or when they look dry.

- Wipe-down: Remove chips, dust, and debris from exposed surfaces, guides, and work areas. Clean drive rollers only with soap, water, and a Scotch-Brite pad—never solvents.

Weekly

- Visual inspection: Look for loose hardware, abnormal wear, rubbing, or anything out of place.

- Chains: Check tension (snug, not tight) and condition; look for rust or dryness.

- Hydraulics: Check oil level and condition; top off per manual specs.

Every 30 hours of operation

- Main drive gears: Lubricate.

Every 40 hours of operation

- Chains: Lubricate with dry motorcycle chain lube or equivalent.

- Tip: Light applications are better than heavy, messy applications.

Yearly

- Hydraulic oil and filter: Replace annually, or sooner in dusty environments or if the fluid looks contaminated. Replace the filter when the red replacement indicator pops.

General best practices

- Never store material in the rollers.

- Avoid long-term outdoor storage. If you must, cover with a breathable tarp to prevent condensation and rust.

- Keep forming rollers clean. Follow the manual—polyurethane drive rollers should never be cleaned with harsh chemicals.

- Lockout/Tagout and remove power before maintenance, adjustments, or changeovers.

What’s Different for SSQ3 Maintenance?

The SSQ3 improves machine protection, adds top cover window visibility, and provides ease of upkeep in several areas. Here’s what streamlines your routine:

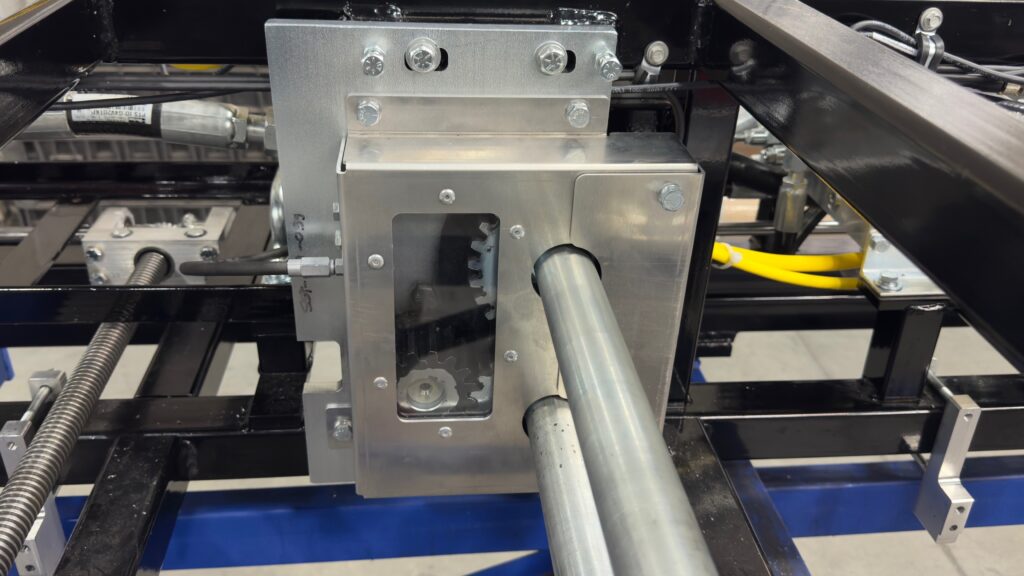

1. Main drive gear cover for safety, extra protection, and easy maintenance.

- What’s new: A two-piece protective cover shields the three main drive gears from dust, chips, and overspray—and helps keep hands out for safety.

- Why it matters: Cleaner gears, easier lubrication, and less debris migration.

- How to use it:

- Quick checks: Use the top cover windows and interior LED lights to verify there’s a visible “wet” film of grease on the gear teeth.

- Deep clean: If you’ve over-greased and the cover is collecting excess, remove the cover and clean. With top covers off and the machine locked out, removing the gear cover should take ~5 minutes. It’s designed so you can remove one side and slide the other away.

2. Easy and quick lubricating with an external grease point for the main drive gears

- What’s new: A grease line easily and cleanly delivers lubricant directly to the gears, replacing the open-spray approach on earlier machines and simplifying the process, saving you time. Prevents lubricant residue from spreading to other interior components to help you keep your machine clean.

- Frequency: About every 30 hours of operation is the benchmark. Practically speaking, one pump weekly is a good habit for most contractors using the machine regularly.

- Amount: Start with one pump of high-pressure grease through the line per interval. More is not better—over-greasing only creates cleanup and can fill the cover.

- Visual cues:

- Healthy: Gear teeth appear wet/tacky with an even film.

- Needs attention: Teeth look dry or hazy. Add a small amount—do not flush or wipe down the gears; just re-establish a light, even film.

3. Chain lubrication approach

- Guidance update: Light applications more frequently are better than heavy, infrequent soaks. Over-lubed chains sling oil, attract grit, and make a mess.

- Interval baseline: Every 40 hours of operation. In the field, that often translates to once a week under normal use. If the machine sits idle for several weeks, inspect before you lube; reapply only if the chain looks dry.

4. Quick-Change rail cleanliness

- What’s new: The SSQ3 quick-change system relies on clean rails and latching surfaces to operate smoothly to save you time and simplify operations.

- Do this:

- Keep rails and latch areas free of chips, sealant, dirt, and buildup.

- Before swapping tooling, wipe the contact surfaces. Debris that a bolt-down system might “crush through” can interfere with the SSQ3 latch action.

- Symptom of neglect: Latches get stiff or require excessive force.

5. Bearings at the back end

- Reminder: There are grease points for bearings that some users overlook, but need lubricating.

- Action: Include these zerk fittings to simplify your routine. If the threads or bearing areas look dry, add EP grease with a grease gun until a film is present—avoid overfilling.

6. Acrylic window care

- What’s new: SSQ3 uses acrylic windows in the gear cover for increased user visibility and easy diagnostics.

- Cleaning: Use Windex or a mild glass cleaner and a microfiber cloth. Avoid abrasive pads and aggressive solvents. Do not pressure wash the windows.

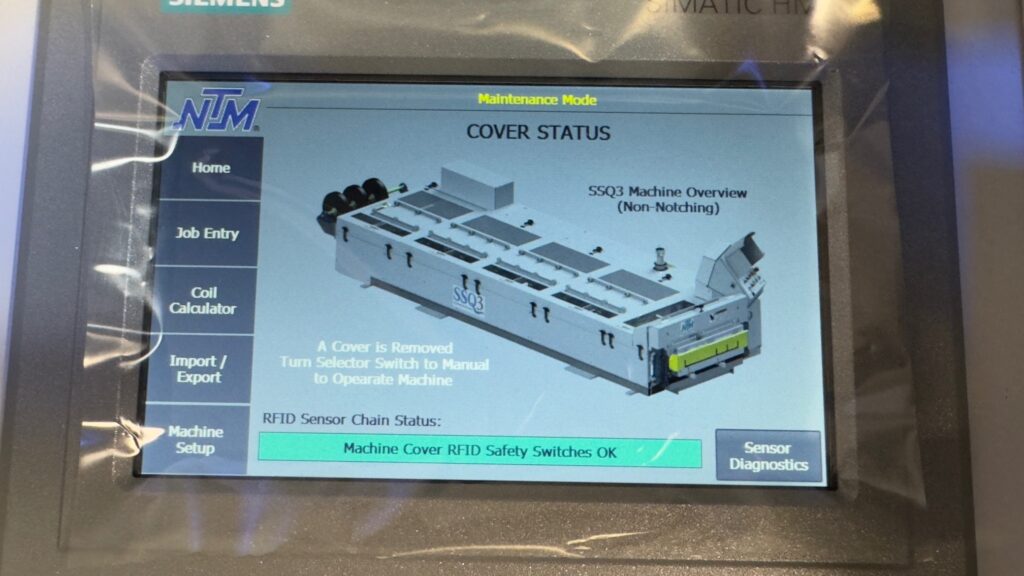

7. Controller and sensors

- SSQ3 cover sensors diagnose offset covers and identify them on your controller, so you can quickly set the cover back in place and keep rolling.

SSQ Maintenance FAQs

Practical Lubrication Tips from the Field

- Main drive gears: One pump via the remote line ≈ a short, targeted spray on older models. Because the SSQ3’s system is direct and contained, err on the side of less per interval.

- Chains: Dry motorcycle chain lube is preferred. Light, even coverage. Wipe excess.

- Shear: If cut edges dull or look torn, re-lube immediately. Proper shear lubrication also prevents rust on blades and dies.

SSQ3 Quick Checklist

Before operation

- Check chains for snug tension

- Verify visible grease film on main drive gears through the window

- Confirm shear blades/dies are lubricated

- Ensure rails and latch faces are clean if you’ll be swapping tooling

- Look for loose fasteners, debris, or anything unusual

End of day

- Wipe chips and dust

- Clean drive rollers with soap/water + Scotch-Brite if needed

- Lightly lube shear if surfaces look dry

Weekly

- One pump to main drive gears via grease line

- Inspect and lube chains if due

- Check hydraulic level and fluid condition

- Hit overlooked grease points (rear bearings, arbor nuts, acme shafts and mitre gears as needed)

Yearly

- Change hydraulic oil and filter; sooner in dusty conditions or if contamination is observed

Safety

- Lockout/Tagout and remove power before any maintenance or changeovers

- Guards stay on during operation; remove only for maintenance with power disconnected

Maintenance Interval Chart (SSQ3)

| Daily or at ~30 cuts | Weekly | ~30 hrs runtime | ~40 hrs runtime | As needed | Yearly |

| Shear blades and dies: Spray lube on both faces; reapply when dry or cut quality declines | Main drive gears: 1 pump high-pressure grease via remote line; confirm film through window | Main drive gears: Lubricate (align this with your weekly routine if usage is regular) | Chains: Lubricate with dry motorcycle chain lube or equivalent; keep applications light | Drive rollers: Clean with soap, water, Scotch-Brite when marking occurs; never use solvents | Hydraulic oil and filter: Replace; earlier if dusty environment or contamination is present |

| End-of-day clean: Wipe down machine; remove chips and debris | Chains: Inspect tension and condition; lubricate lightly if due | Entry guide carriage, bead roller carriage shafts, acme shafts, mitre gears: Light spray lube per manual | |||

| Clean drive rollers with soap/water + Scotch-Brite if needed | Hydraulics: Check oil level and clarity | Arbor cradles: Clear grease as required | |||

| Lightly lube shear if surfaces look dry | General inspection: Hardware snug, rails and latch surfaces clean, windows clean | Arbor nut threads: EP grease when threads look dry | |||

| Hit overlooked grease points (rear bearings, arbor nuts, acme shafts and mitre gears as needed) | Quick-Change rails and latch surfaces: Keep wiped clean to ensure smooth, safe operation |

Troubleshooting signals to act on

- Panel markings/stripes: Clean drive rollers with soap/water; inspect for trapped debris

- Ragged cuts: Re-lube shear; check blade/die condition

- Stiff Quick-Change latches: Clean rails and latch surfaces; remove debris buildup

- Dry or noisy chains: Re-check interval and lubrication method; avoid heavy, messy applications

- Gear cover pooling grease: Over-lubrication—remove cover, clean, and reduce future amounts

Have a question about your SSQ3’s maintenance, lubrication products, or intervals? Our service team can walk you through best practices for your exact setup and environment. Contact our service department for more information.

For information about the SSQ3 MultiPro or any of our portable metal roof panel or seamless gutter machines and accessories, contact us.